Seeds

Thanks through our knowledge of product properties we can optimize our processes

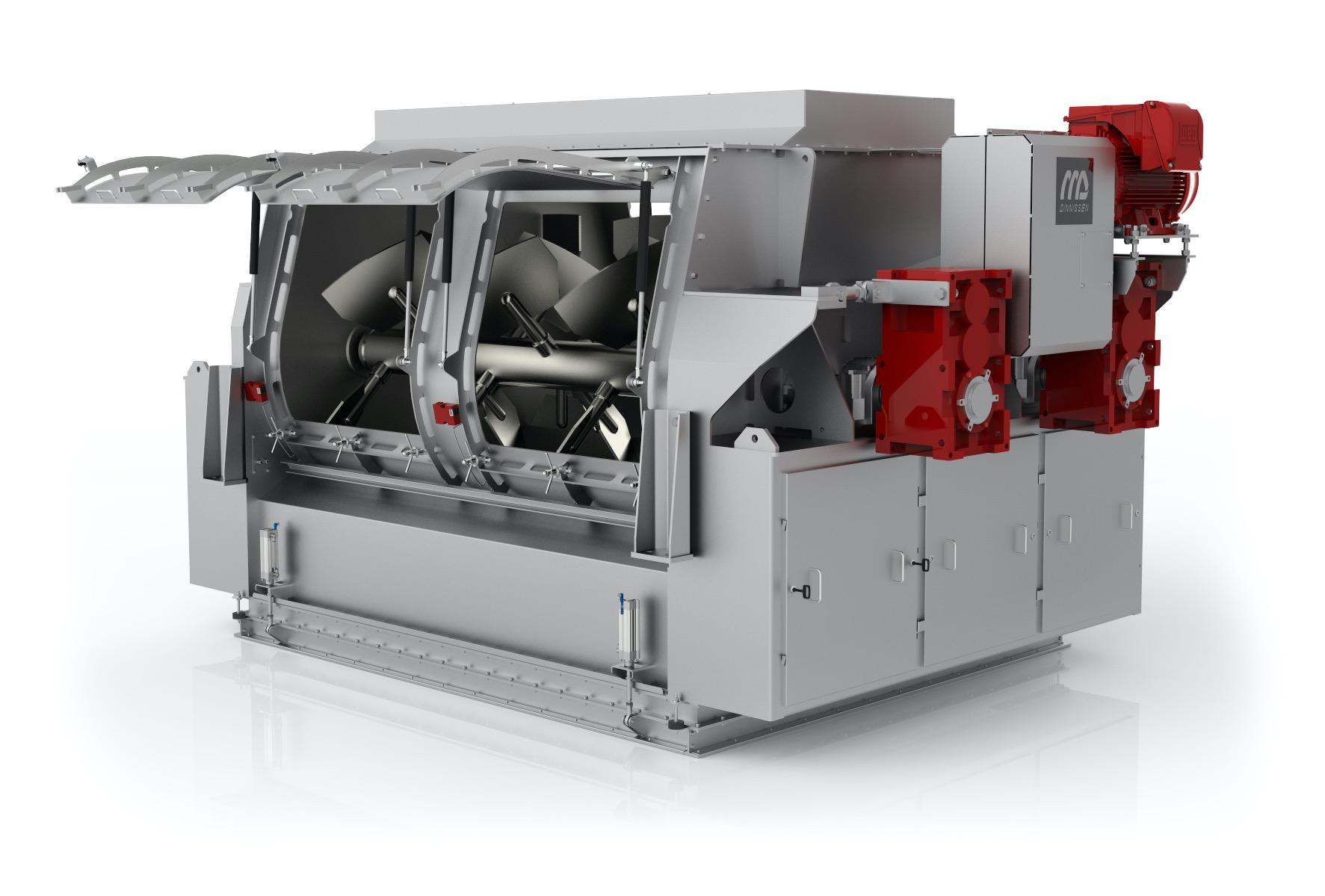

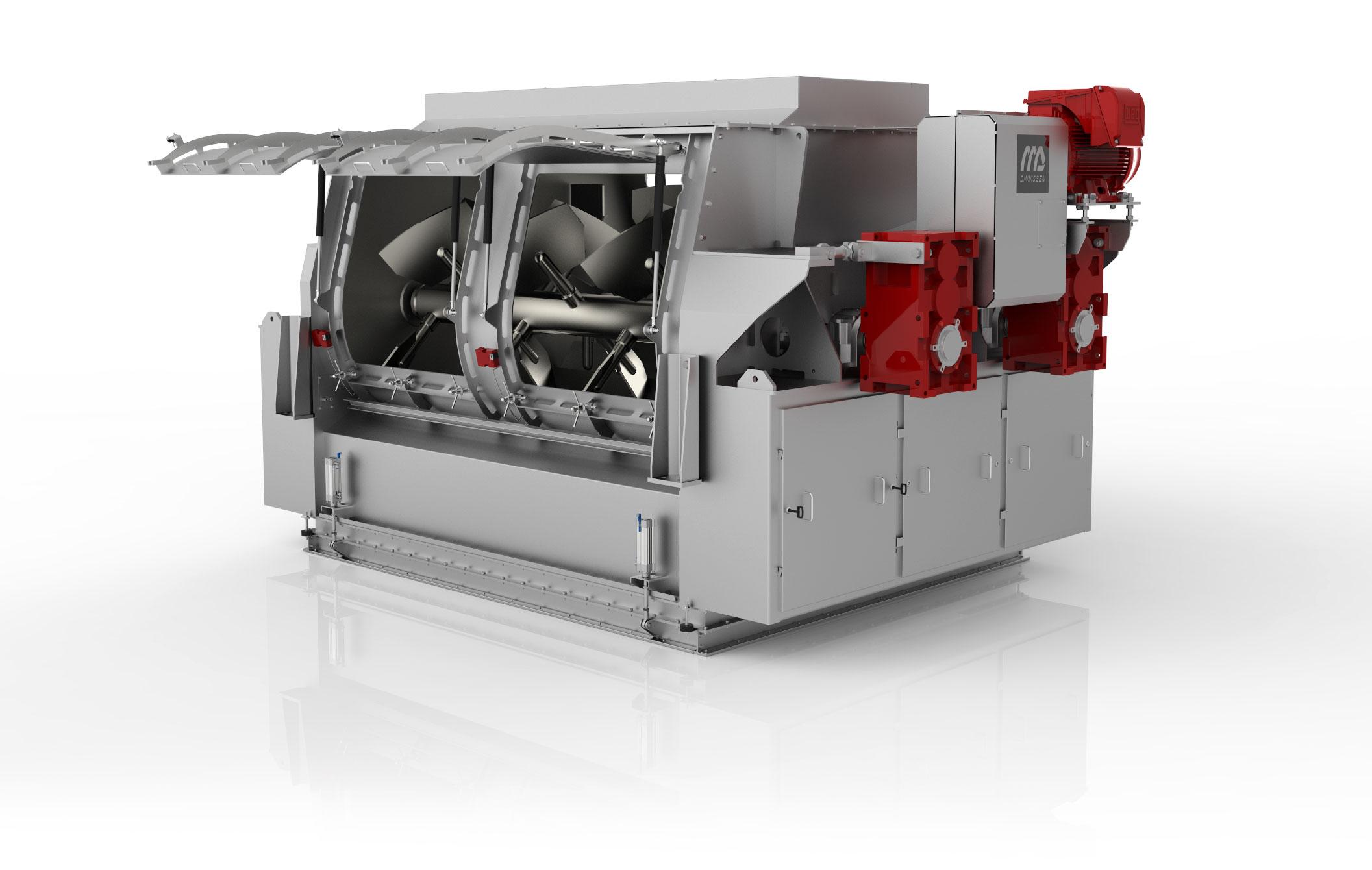

A seed is the most important survival organ in seed plants. The seed is an expanded seed principle or ovule. Seeds can be spread by the plant itself, by trees, plants, the wind or by mechanical machines. We are developing machines for different seeds. Are you producing with seeds? Dinnissen surely can help you to find the right solution for your seeds process.

Thanks to our team of experienced food specialists, Dinnissen Process Technology has knowledge of many product properties. This enables Dinnissen to efficiently design innovative processing lines. This way we can offer our customers a solution that perfectly suits seeds.