Pea starch processing equipment

Processing lines specially aimed at pea starch

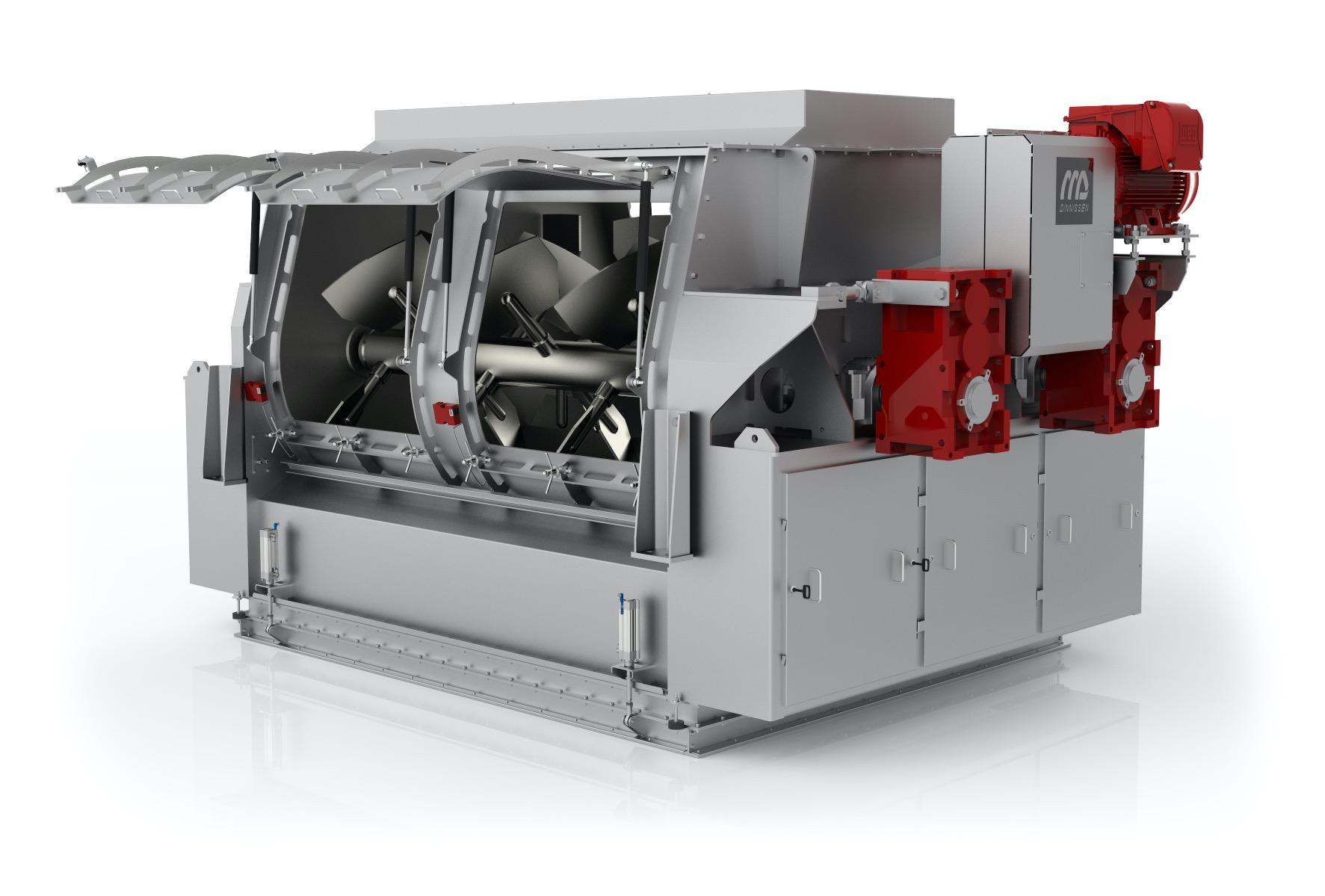

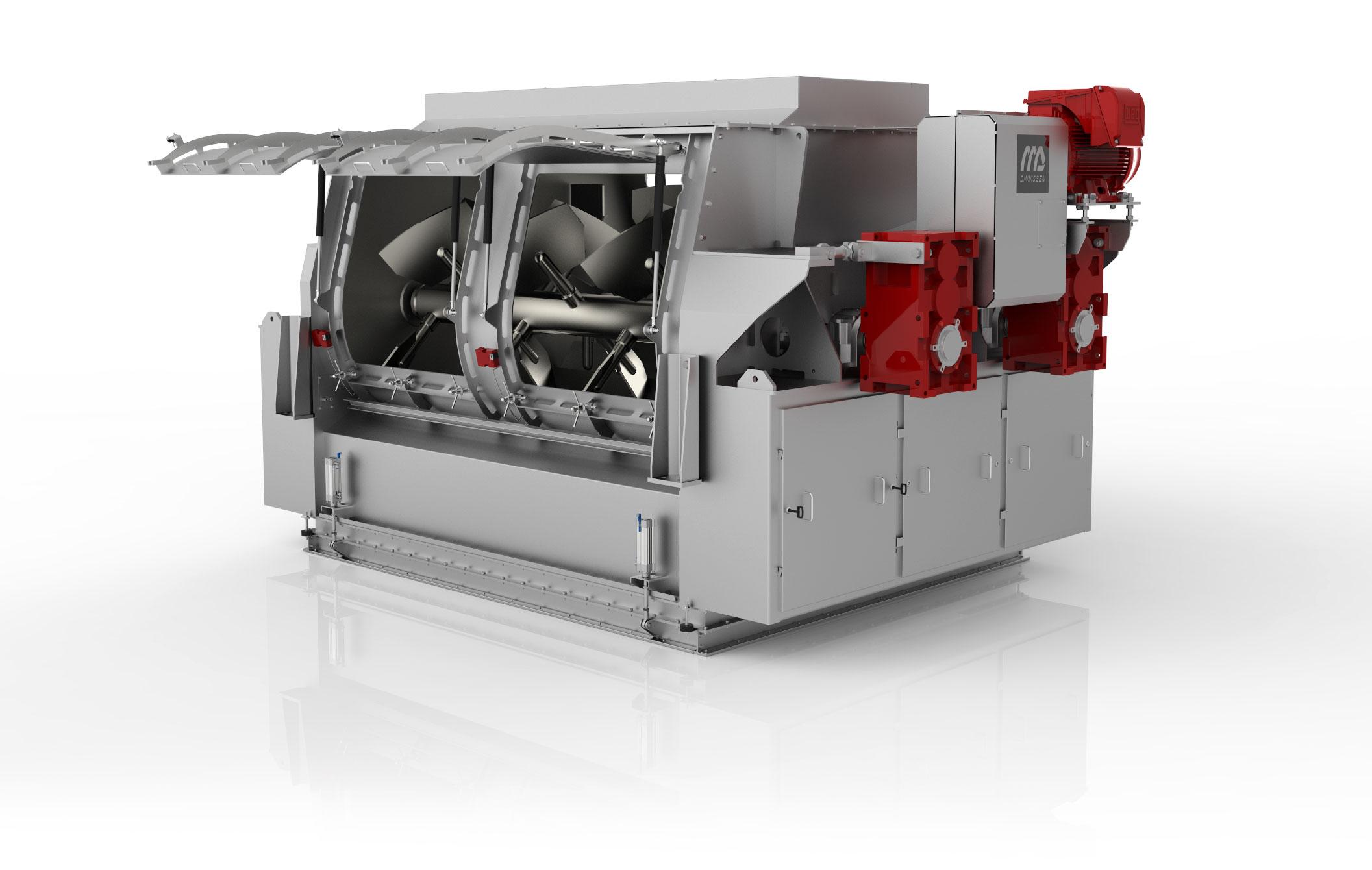

Over the years, we innovated a lot of machines in the food-industry, specially designed for pea starch. For example our Pegasus Mixer. This machine can be completely tailor-made to comply with the specifically guidelines in the food-industry. The fact that multiple steps, like mixing and accurate moistening can be done in just one single step, makes the machine truly the best option for every producer working with pea starch.

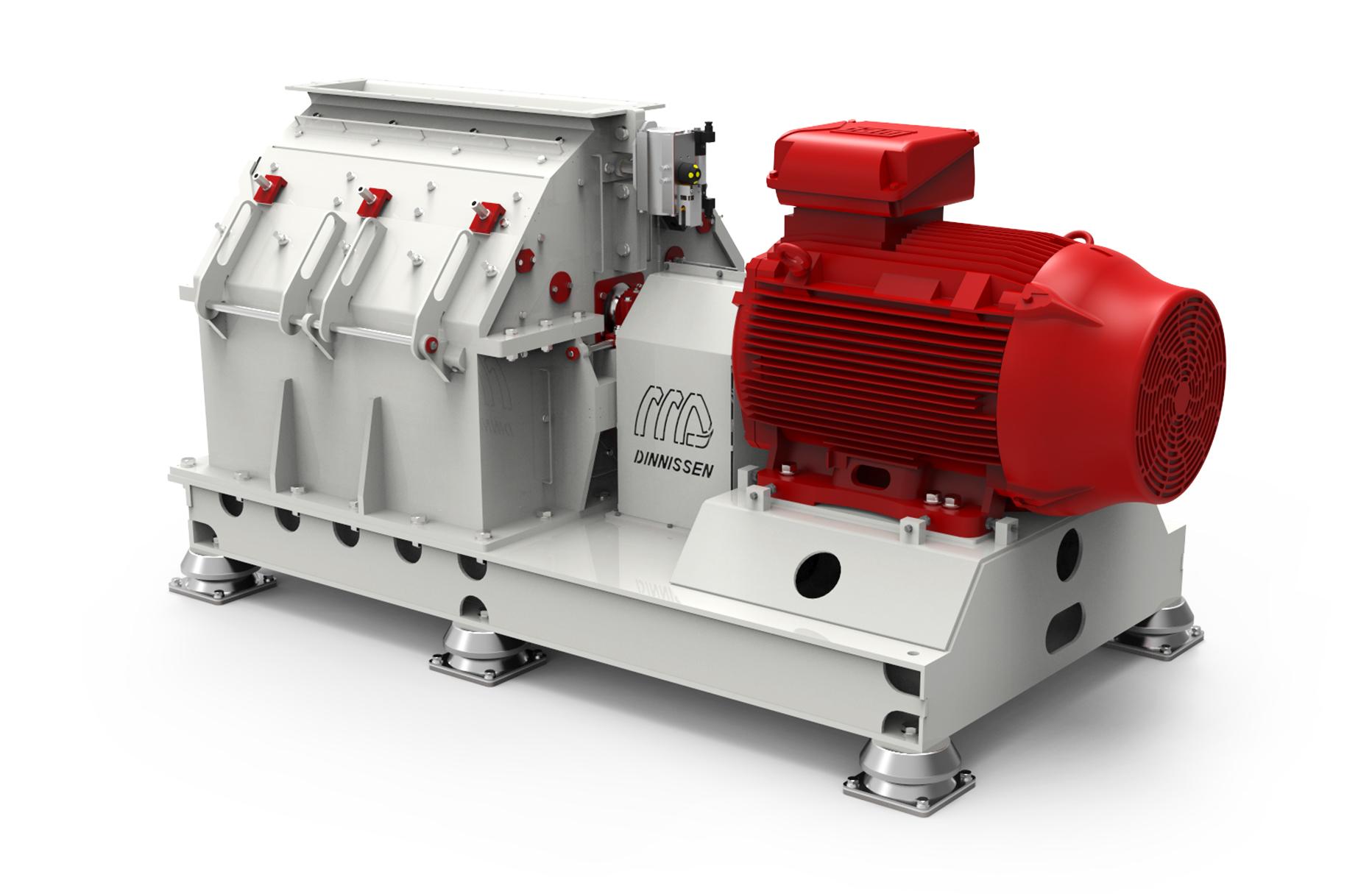

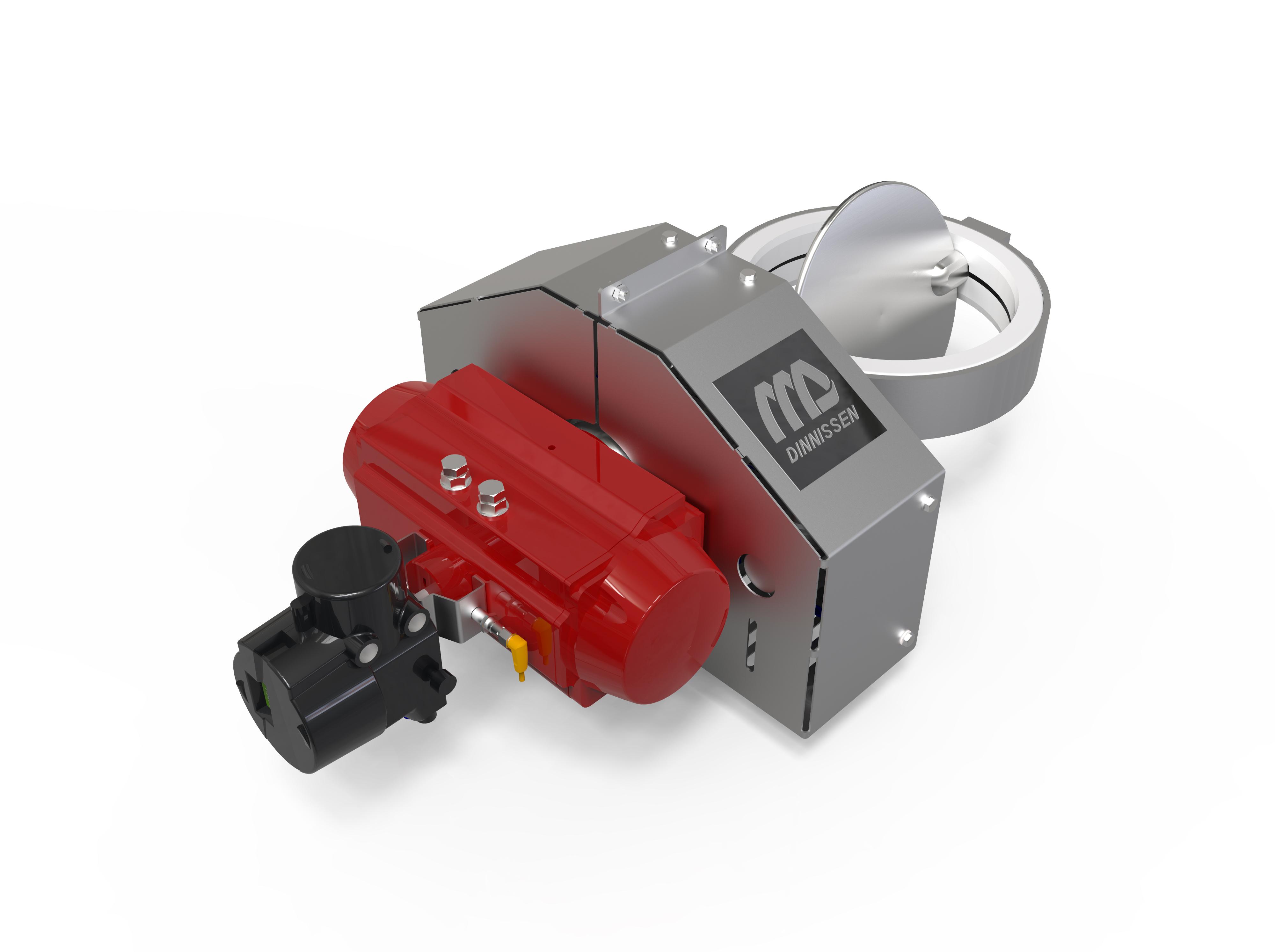

Another impressive machine is the hammer mill, this machine has a very short change time by automatic sieve change which ensures a higher up time / capacity.

Below are some examples of machines and completing processing lines specially designed for pea starch.