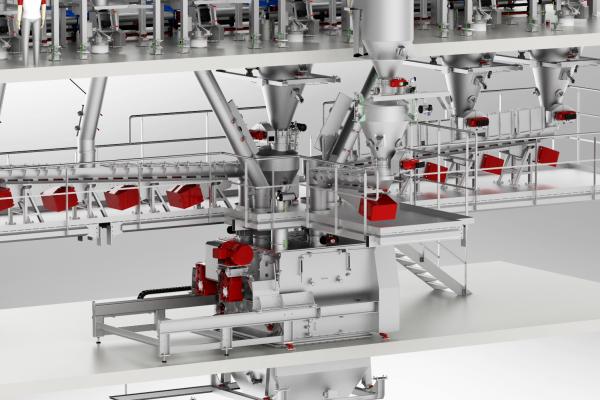

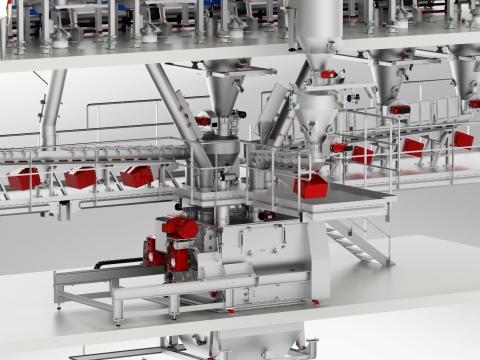

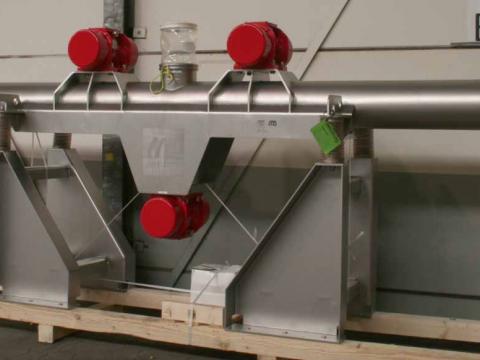

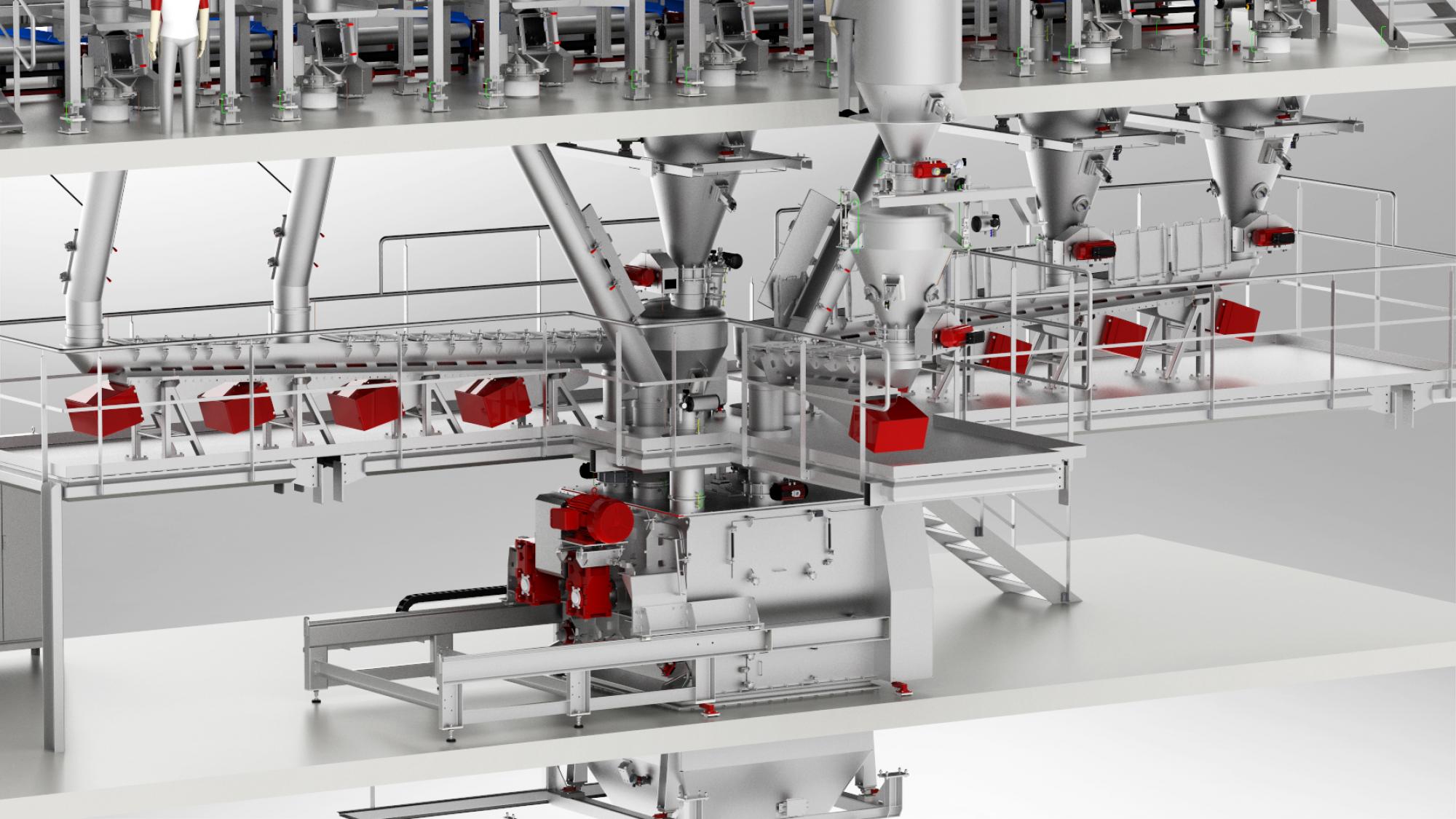

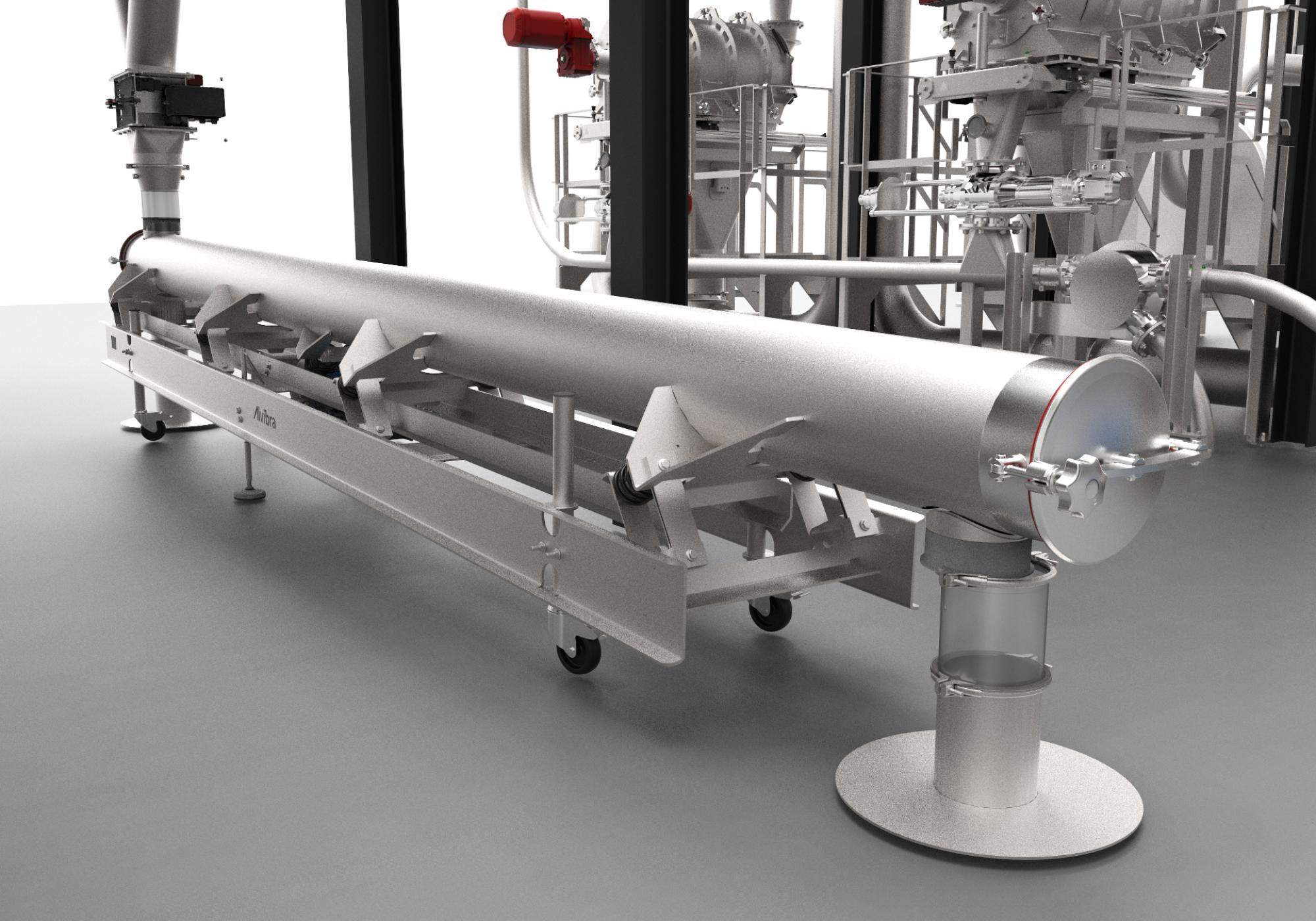

Vibration Transport

Vibration transport is a form of mechanical transport in which raw materials are transported using a vibrating movement. Vibration transport is an extremely suitable solution for processes with high hygiene requirements because no rotating parts are used and the system is easy to thoroughly clean. You can choose either a trough or a tube, whereby the tube can be fitted with access hatches to facilitate inspection and manual cleaning.