Key features, options, and models

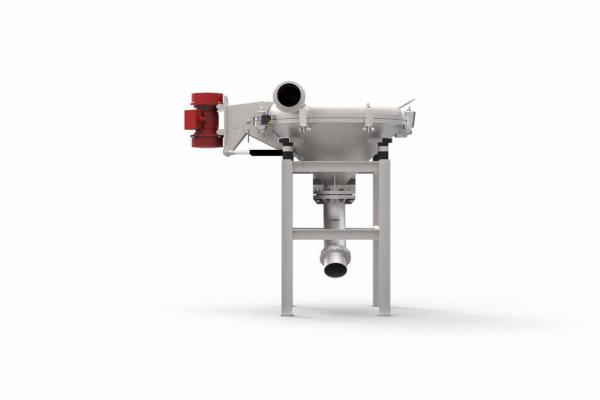

Every Vibrating Sifter contains a screening deck with horizontal vibration. Due to this vibration of this sifting deck, the smaller particles on the sifting deck fall through the sifting deck via the perforations. The larger particles remain on the sifting deck. There are various versions of the Vibrating Sifter. For example, several sifters can be mounted on top of each other. This creates different groups of product, selected for fineness. In addition, the sifting deck can move vertically, as well as horizontally.

Vibrating Sifters can ensure that the product that cannot pass through the sifter perforations is moved horizontally by the vibration. As a result, this machine is also referred to as a vibrating sifter. Dinnissen's Vibrating Sifters are available in different (round and rectangular) versions, in various material types, including specific cleaning options with air, impact, or ultrasonic vibrations. Ultrasonic vibrations create a more uniform movement, and the grains pass more easily through the perforations of the screening deck. This technique reduces the chance of clogging the sifting deck.