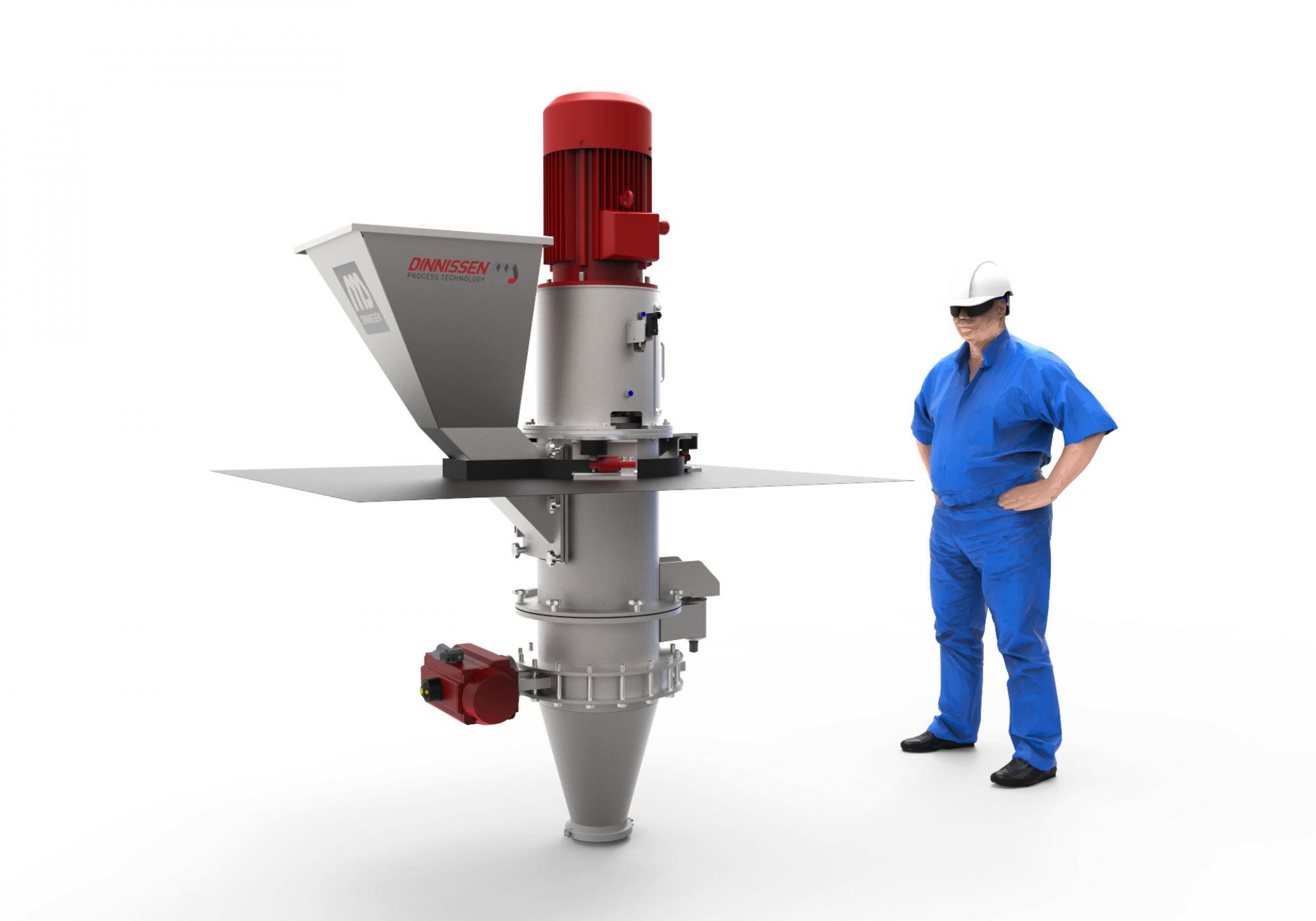

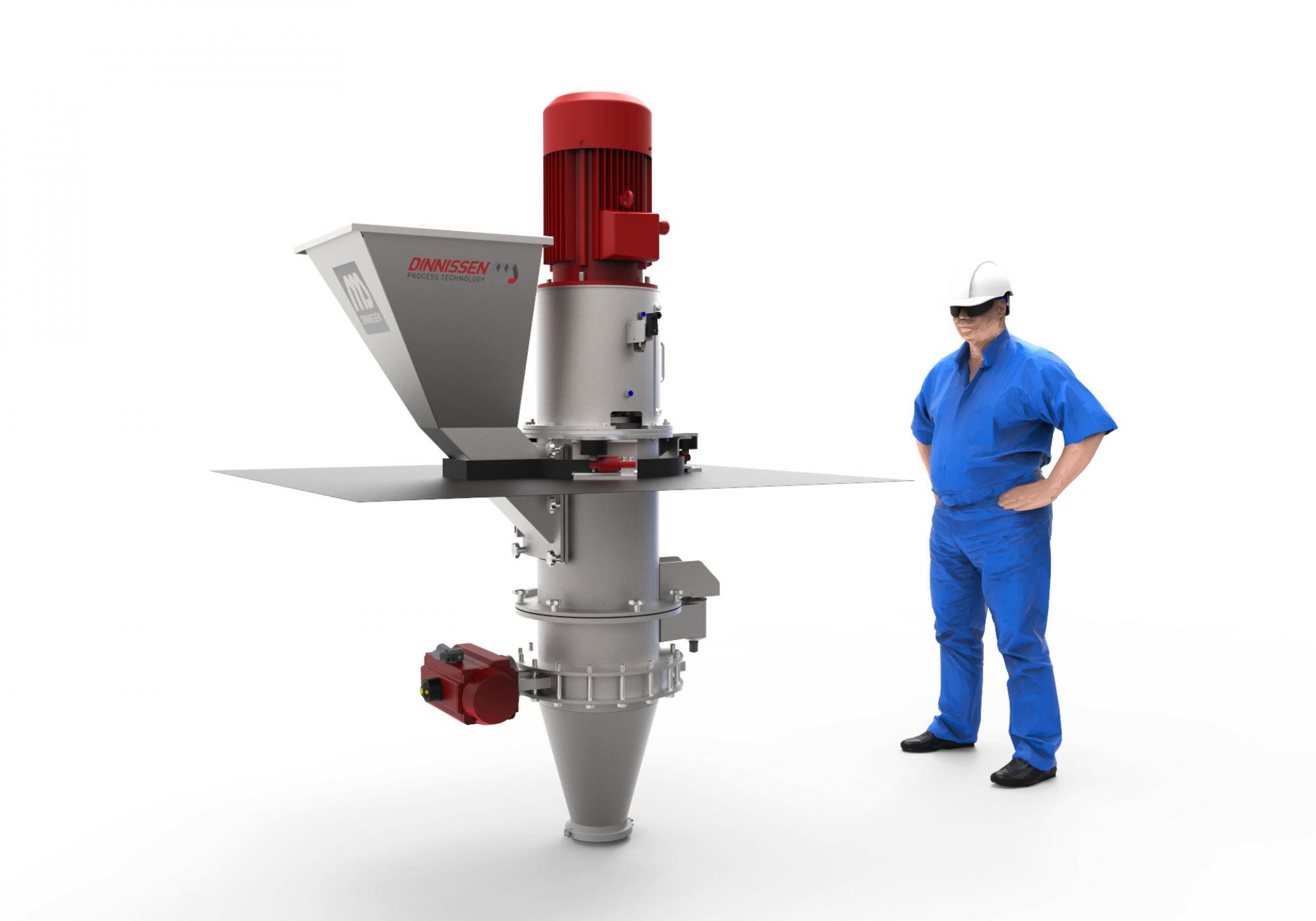

Shredder

Shredders are particularly suitable for reducing soft and tough products. Available in various types of material, Dinnissen shredders are fitted with one or two rotors with hardened, wear-resistant, and easily replaceable blades.

Shredders are particularly suitable for reducing soft and tough products. Available in various types of material, Dinnissen shredders are fitted with one or two rotors with hardened, wear-resistant, and easily replaceable blades.

Process:

Dinnissen shredders were developed for the safe and quick shredding of various products in both the food and feed industry and in other industries such as the recycling industry. The shredders contain one or two rotating rotors with blades attached. The distance between the blades and the housing is adjustable and determines the product fineness.

To achieve exactly the desired grind fineness, the clearance between the directly driven rotor and the housing is accurately adjustable. Thanks to the modular configuration and the frequency-controlled variable rotor speed, Dinnissen shredders ensure accurate and uniform product reduction over and over again. The shredders can be used for such purposes as the reduction of leafy herbs, chili peppers, gelatin, and cellulose sheets, as well as plastic and rubber reduction.

In addition to the space between the directly driven rotor and the housing, the clearance between the blades is also very important for the desired product fineness. This is usually below 0.3 mm. Because the blades are mounted diagonally, the shredded product does not accumulate behind the knives and the product can be shredded continuously and efficiently.

Our shredders are available in various types of material. The blades mounted on the rotors are hardened and wear-resistant, but also easily replaceable. Additional stator blades are present in the grinding chamber. The blades move through the product at a high speed, causing product reduction. Over time, the blades become less sharp, as a result of cutting. For this reason, all Dinnissen shredders contain a simple and fast blade change system.

The effectiveness of reducing a given product depends on the product properties, the geometry of the blades and the cutting speed. The cutting speed can be diversified because the speed of the rotors is adjustable. The built-in air circulation system ensures low energy consumption at low capacities. If desired, the shredder can be designed to be completely gas-tight. This makes the shredder excellently integrable in closed-loop process lines, which must be completely inert.

A shredder works because of shear forces. The material is divided into pieces when the maximum shear stress in a material is exceeded. This happens because the sharp blades in the shredder exceed the maximum shear stress in the material. The shredder works based on the blades moving through the product at high speeds.

The product is in a grinding chamber and usually, two rotating rotors in opposite directions are present, to which the blades are attached. In this process, product reduction occurs through the rotation of the blades attached to the rotors.

There is also another way in which a shredder can operate. In fact, in other types of shredders, the product passes through a stationary ring of sharp blades in a rotating grinding chamber. The blades cut off some of the product particles passing by at a high speed. With this principle, the blades do not move and cut through the material, but the material itself moves against the blades.

Download our brochure or the datasheet with all options, models, and measurements, or freely contact one of our experts.

From hammer mills and shredders to grinders and breakers. In addition to shredders, we can achieve your desired grain or product size with various grinding and crushing solutions, together.

System integrator Dinnissen optimizes and innovates your production process with tailored solutions: developed, manufactured and tested in-house. From product intake, transport, dosing and weighing, mixing, grinding, sieving and packaging to full automation and control. We maximize the performance and efficiency of your entire process.