Thorough and fast cleaning

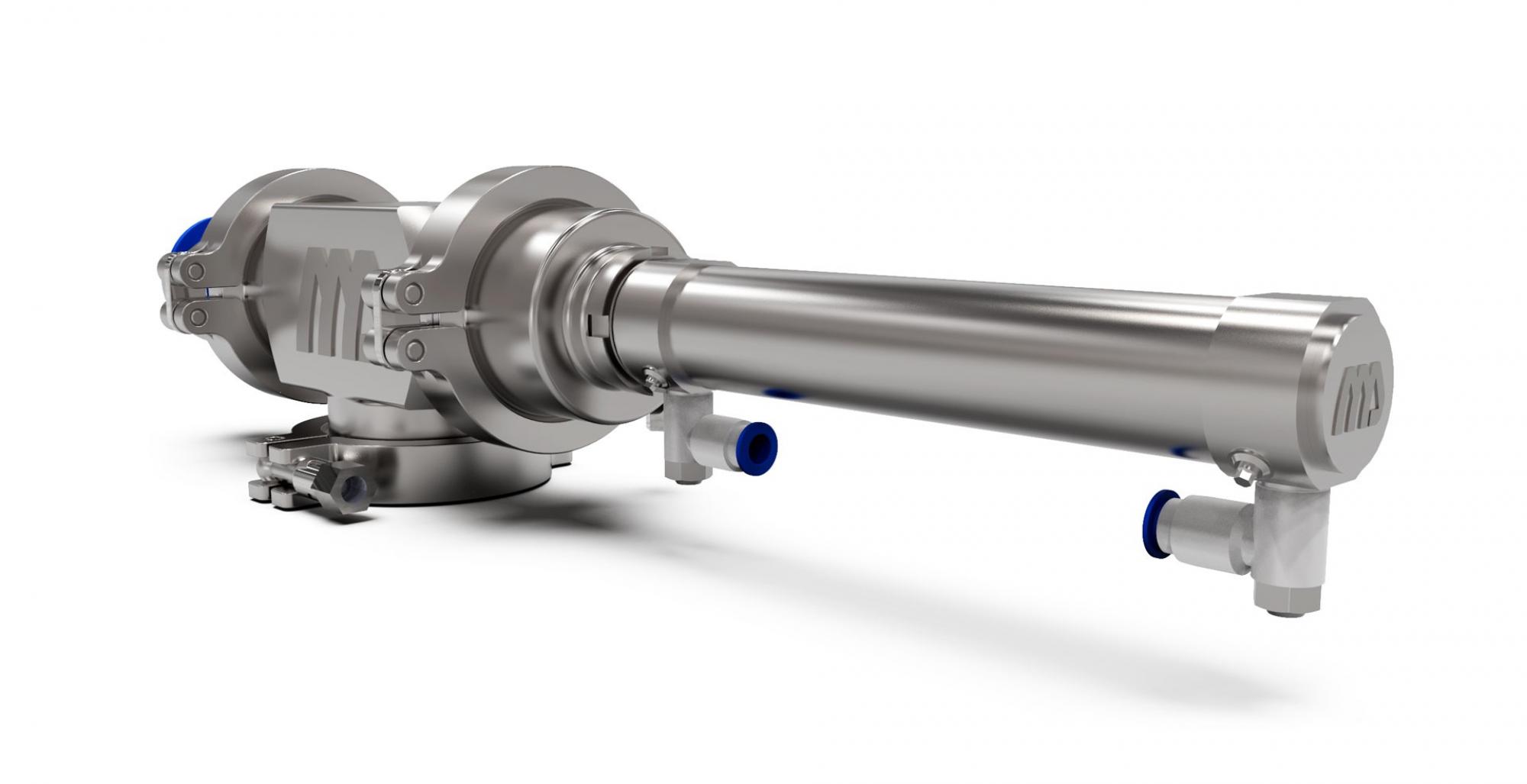

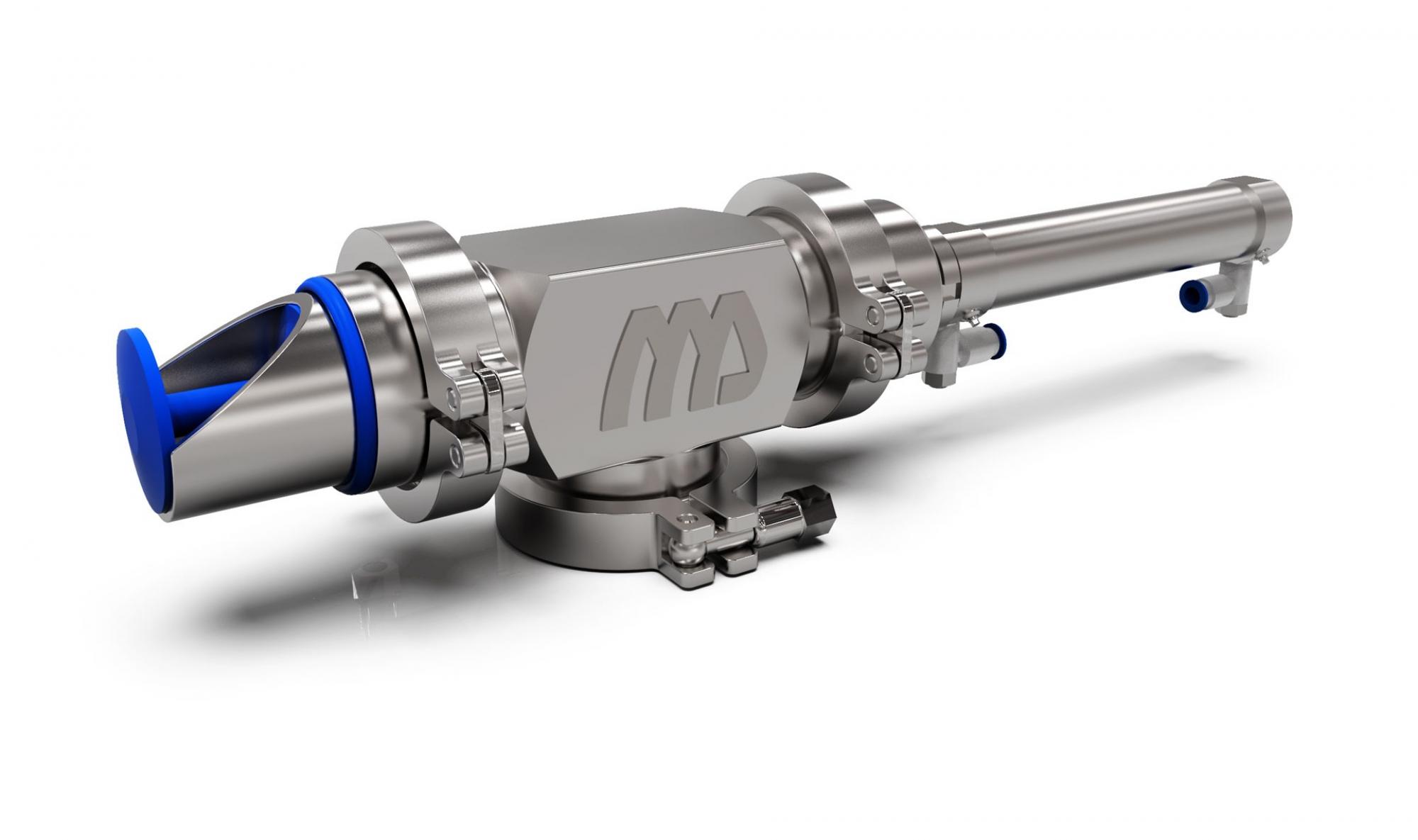

A distinction is made between the standard Sampling System and the premium Sampling System. The standard line is designed for use in hygienic environments, easy to disassemble and clean. When hygiene requirements are even more stringent, the premium line is the best choice. The interior of the premium line consists of only one plastic part with no edges, seams, or gaps. The interior can also be removed and replaced without touching, which prevents sample contamination. As the system’s sensors are integrated into a detachable plastic adapter that can be removed with a single hand movement, the premium Sampling System can be cleaned quickly and thoroughly.

- Easy and fast cleaning

- Designed and patented according to EHEDG and ATEX guidelines

- Capacity from 25 to 1000 grams per sample

- The premium line can be delivered with metal detectable interior

- In the premium line, the plastic is in a food-contrasting color, making detection very easy