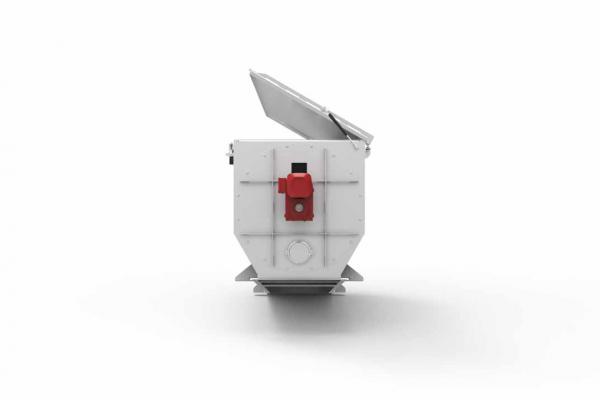

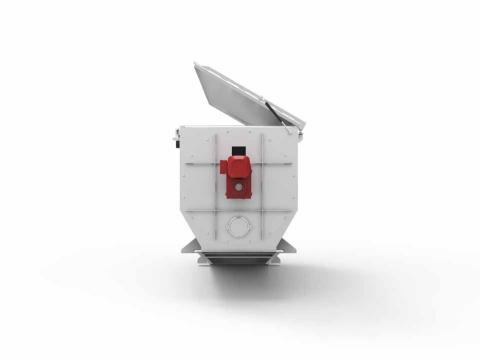

Key features, options, and models

A Rotary Drum Sifter (1 or 2 decks) can be equipped with different sifting perforations. A product can be divided into two groups (fine enough to go through the perforations and too large to go through the perforations), but for example also in three groups. In this case, at the top of the sifter, finer perforations are used through which only grit can pass. The further down the chunks or grains go, the larger the perforations become. The chunks that are the right size for further processing then fall into the lower section. The oversized chunks remain and can be brought back into the process.

The drum sifters are -depending on the desired capacity- available in various construction sizes. Extra-large types are also available for cleaning raw materials. In this variant only impurities are separated. Rotary Drum Sifters can be used for different materials. In addition to dried granules or chunks, more moist and sticky mixtures can also be processed by a Dinnissen Rotary Drum Sifter.