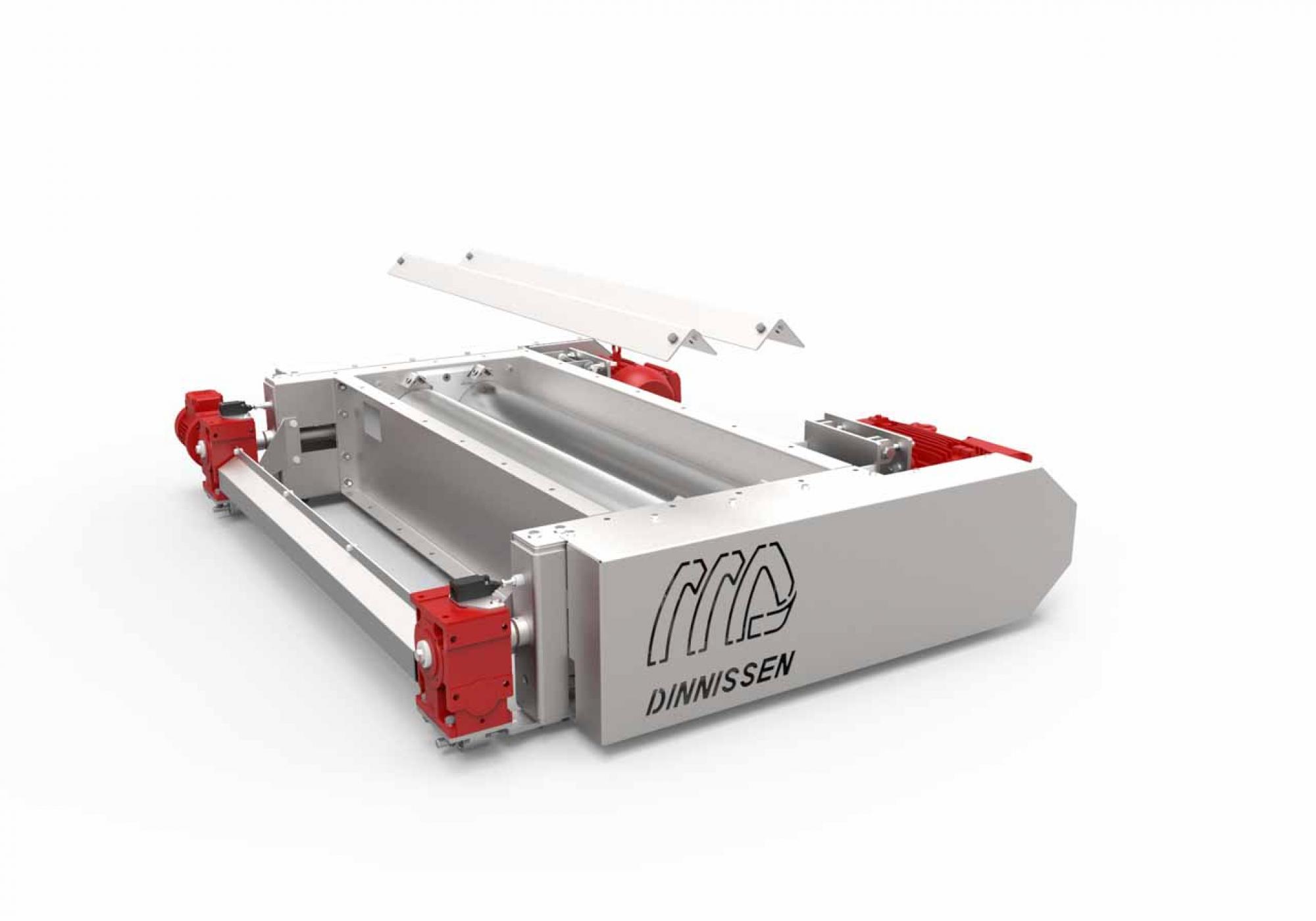

Key features, options, and models

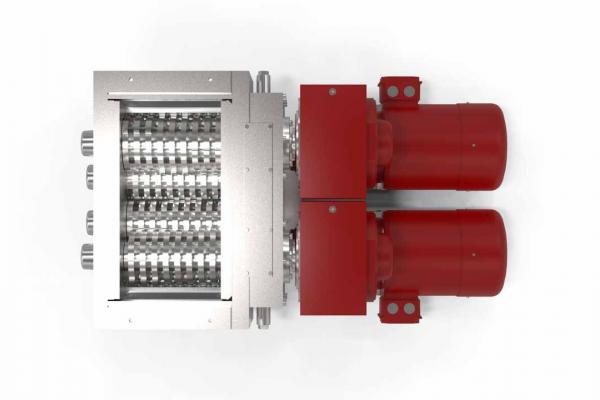

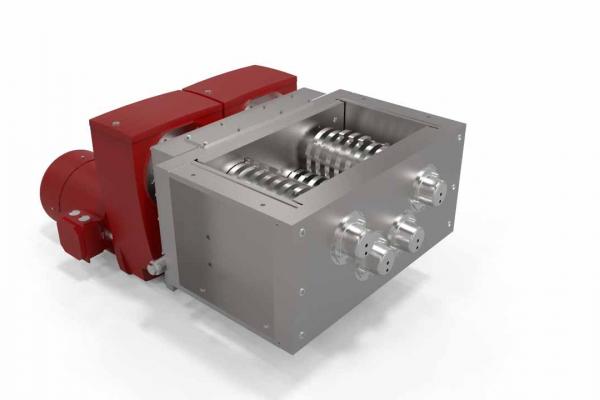

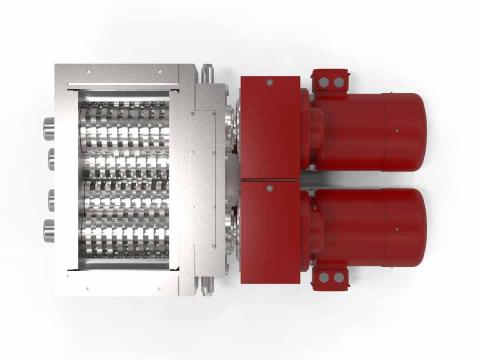

With a roller mill, various products can be crushed and ground. Product refinement occurs through a combination of compressive and shear forces. This principle is especially very suitable for products with a fibrous structure, such as cereals, oilseeds, and biomass. Because the heat generation is very low, it does not affect the products to be processed. The grain size of the product is determined by the profile of the roller and the space between the rollers. For ultrafine product pulverization, several pairs of rolls can be placed one above the other.

When using multiple pairs of rolls, the top two rolls are furthest apart, and the bottom two rolls are closest together. The further the product is in the production process, the finer it gets. A roller mill can reduce the product from medium-fine grains to ultra-fine grains, depending on the product and the desired result.