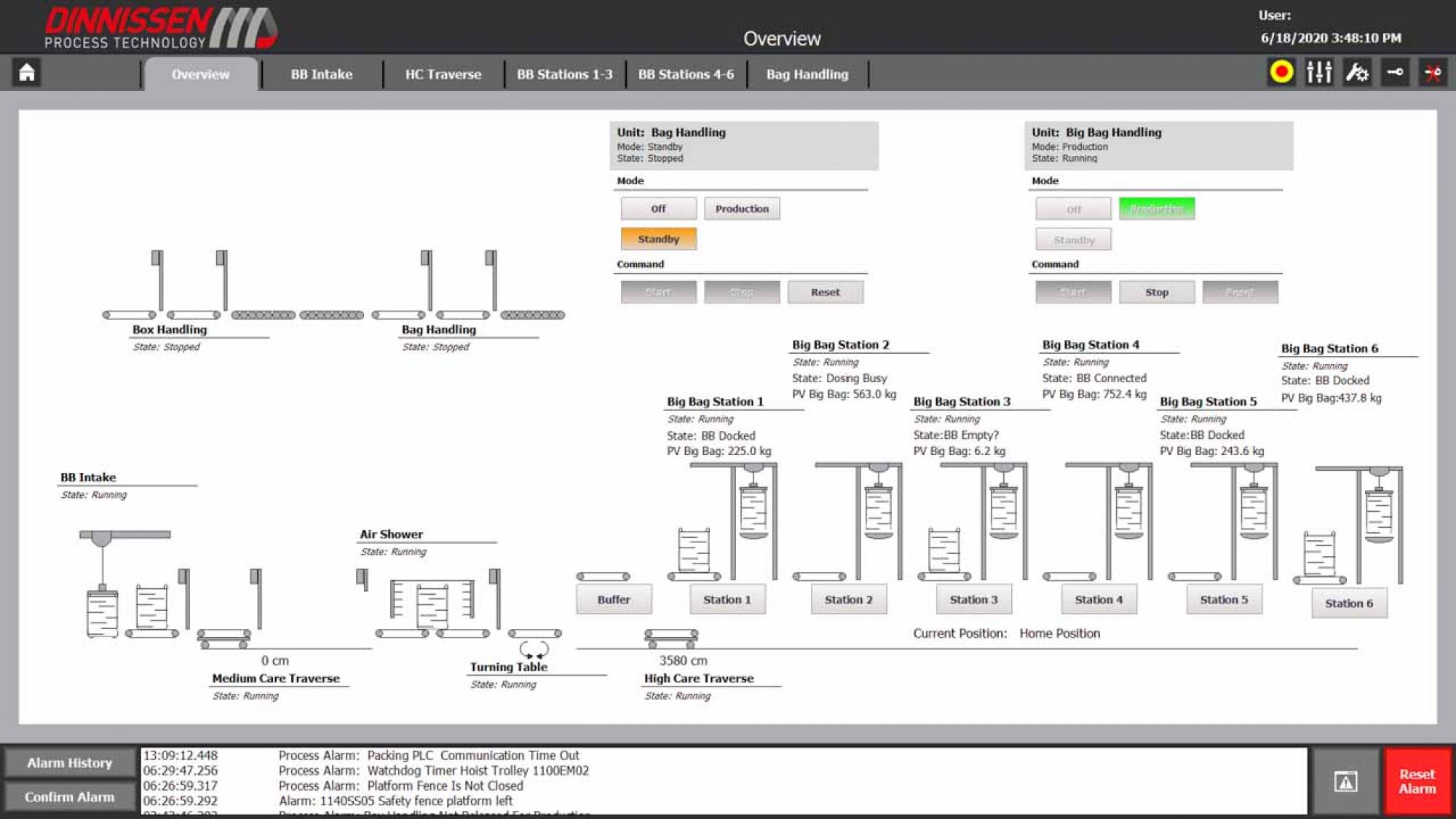

PLC Automation

PLC stands for Programmable Logic Controller. The PLC can control machines and determines what a device should do (when, for how long, how often and how). A PLC could be described as a robust computer, that works well in an industrial environment. Dinnissen has an internal automation department that develops perfectly functioning PLCs, tailored to the market of grains, powders, and granulates.