A fast and efficient process

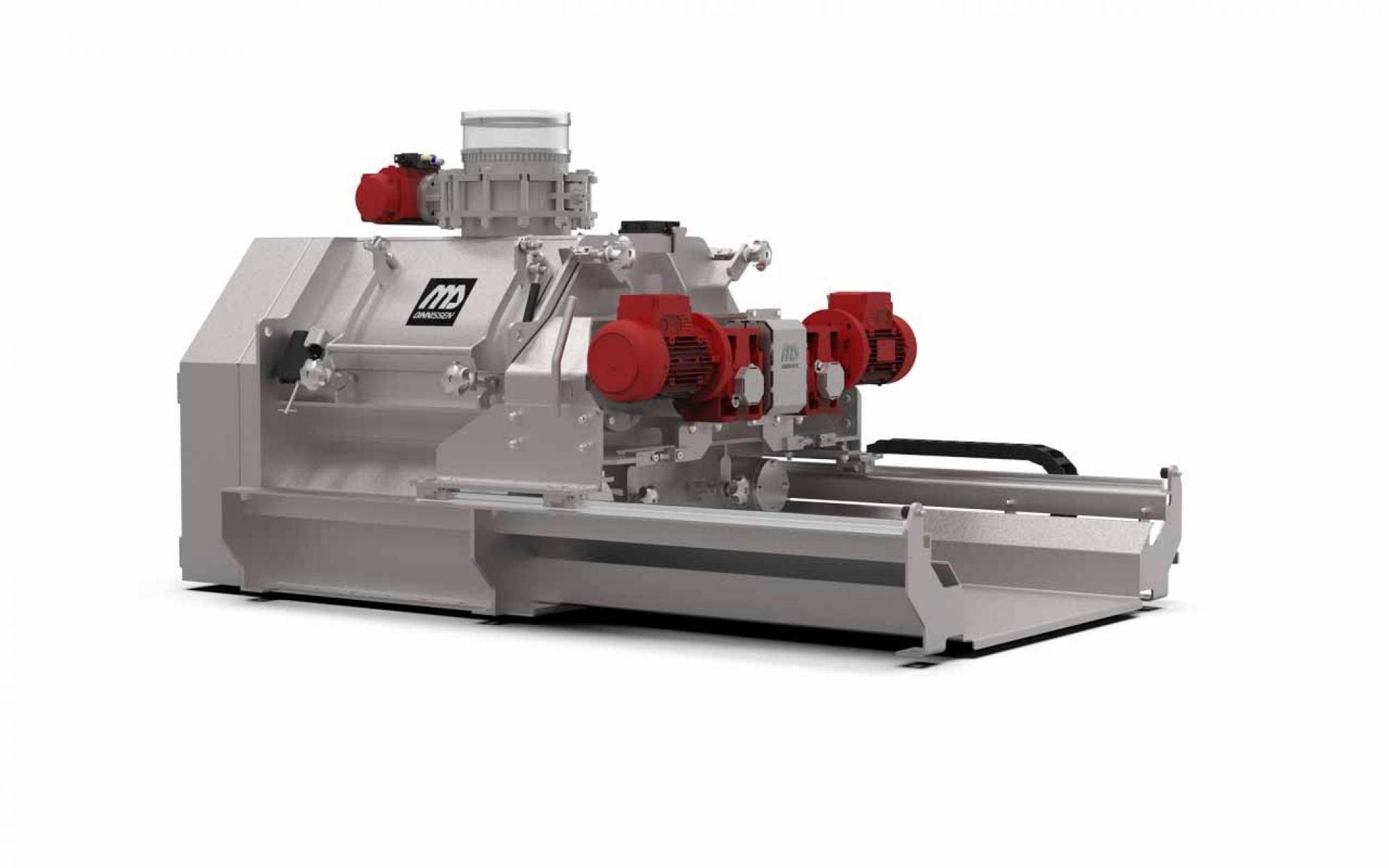

By combining several process steps in one machine, the Pegasus® 5-in-1 mixer saves on both cost and energy. The dual axis mixing mechanism airily tosses powders, pellets and granules during mixing. Then the finely atomized liquid particles mix homogeneously with the dry raw materials. The 5-in-1 mixer can also dry, germinate and acidify the product. No transport is needed between the different process steps, saving time and manpower. The various process combinations make this mixer very suitable for practically any producer, in any industry, for any process.

- Energy-efficient solution

- Less time and manpower required

- Suitable for almost any process

- Hygienic and easy-to-clean design

- Designed, developed, and tested in-house