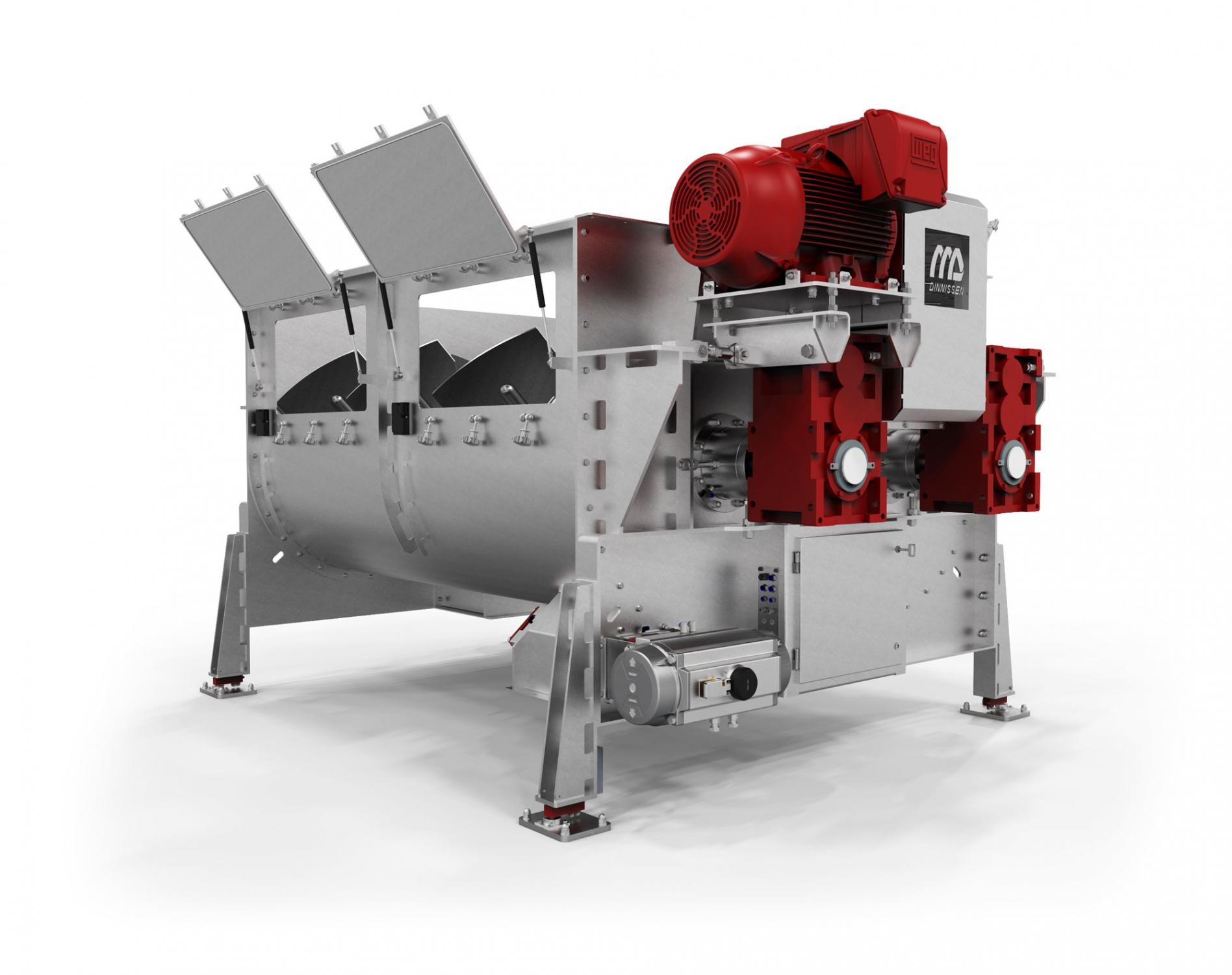

Mixing & Processing

Meet Dinnissen's Pegasus® machines: robust double-axis mixing machines designed to homogeneously mix all types of powders, grains and granules. To achieve the most efficient production process possible, multiple process steps can be carried out in one single machine. This not only saves time but space as well. Mixing can be combined with vacuum coating, heating, cooling, drying and more. We like to work with our customers to best meet their needs.