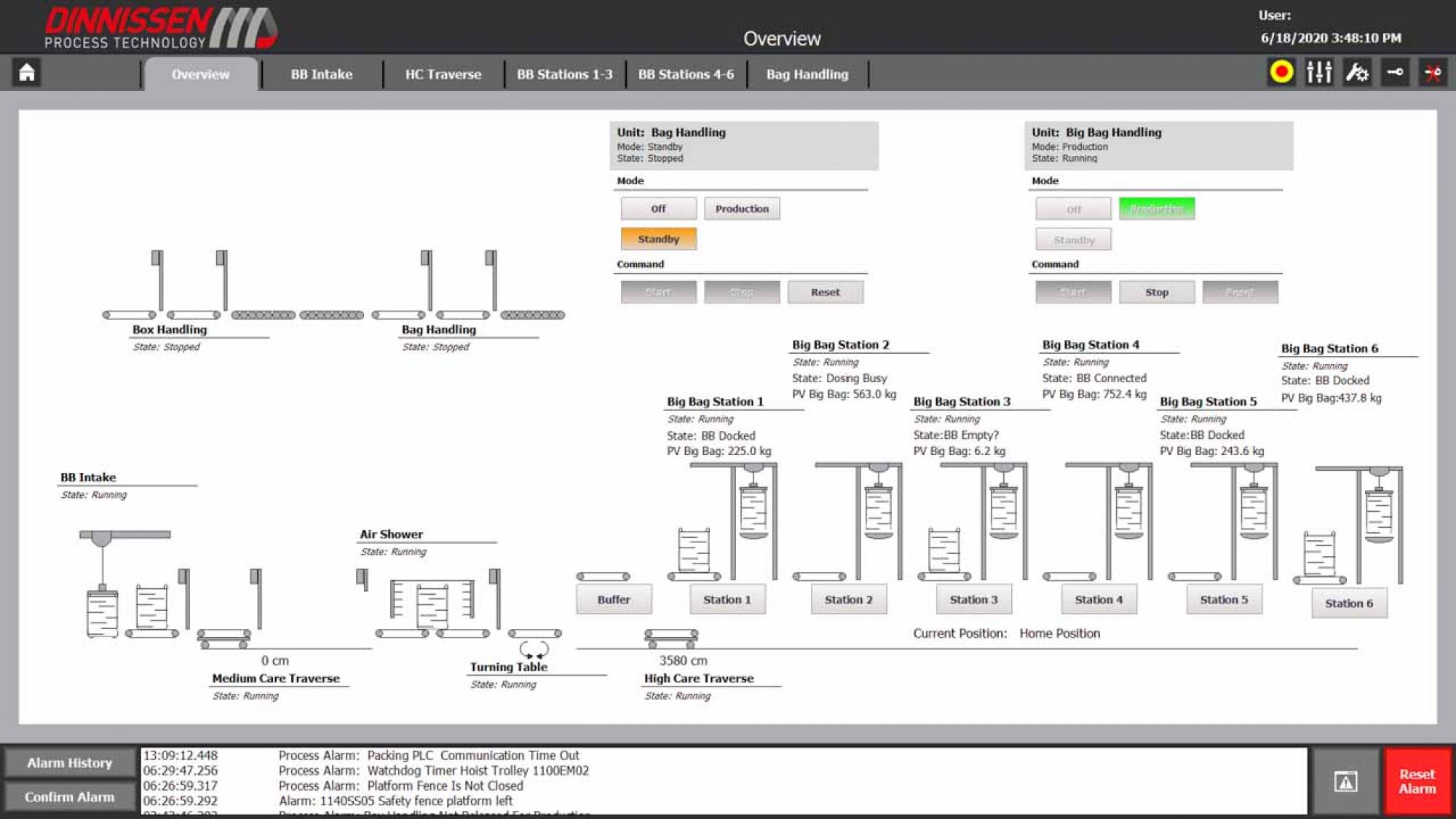

HMI OneBlink

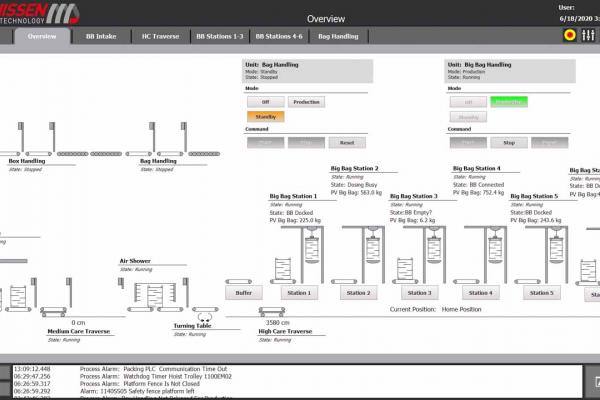

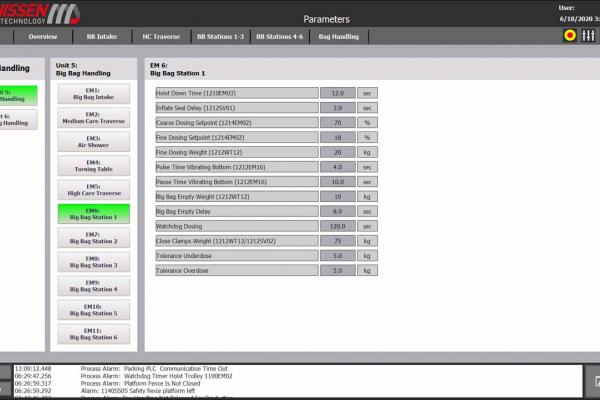

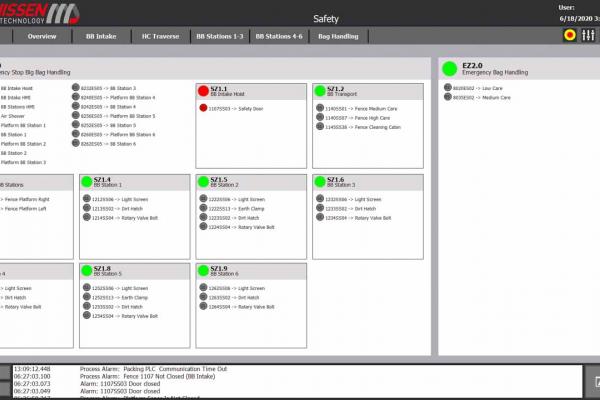

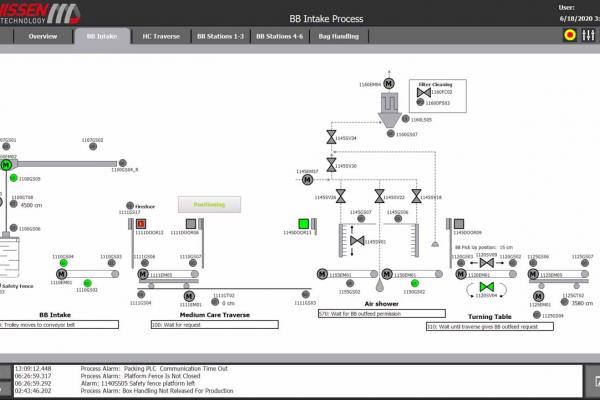

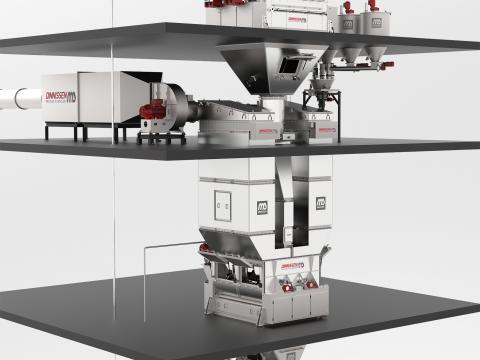

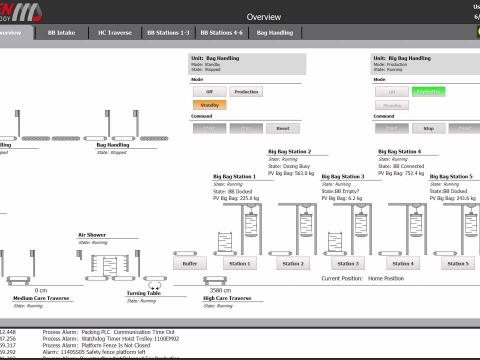

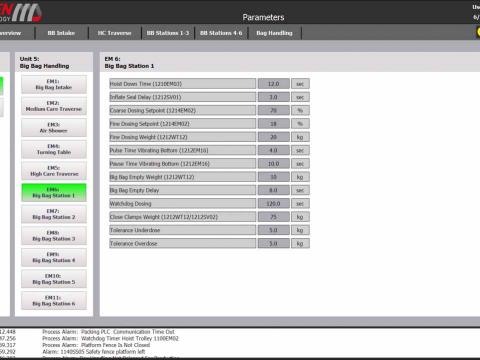

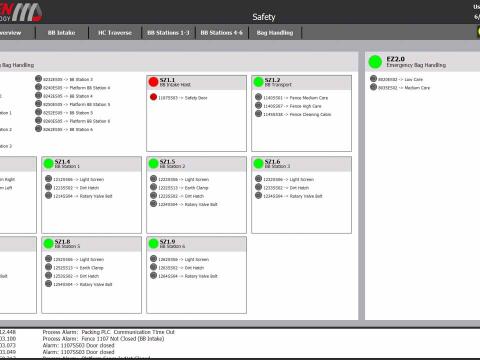

Over the last few years, Dinnissen has developed the HMI OneBlink, a human-machine interface. This interface is designed based on usability and ease of use. The HMI OneBlink allows operators, technical services, and other users to see the status of the entire process line at a glance.