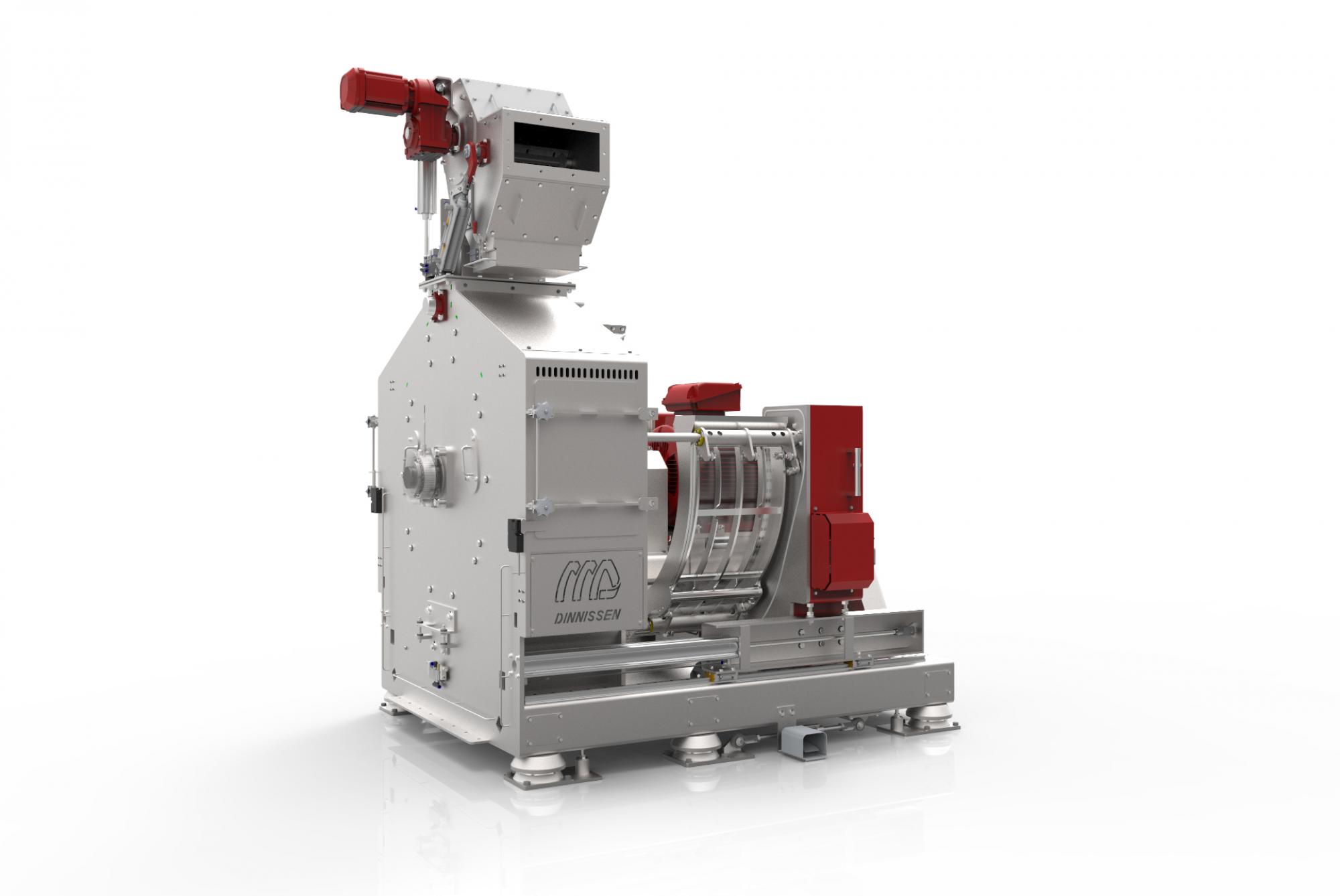

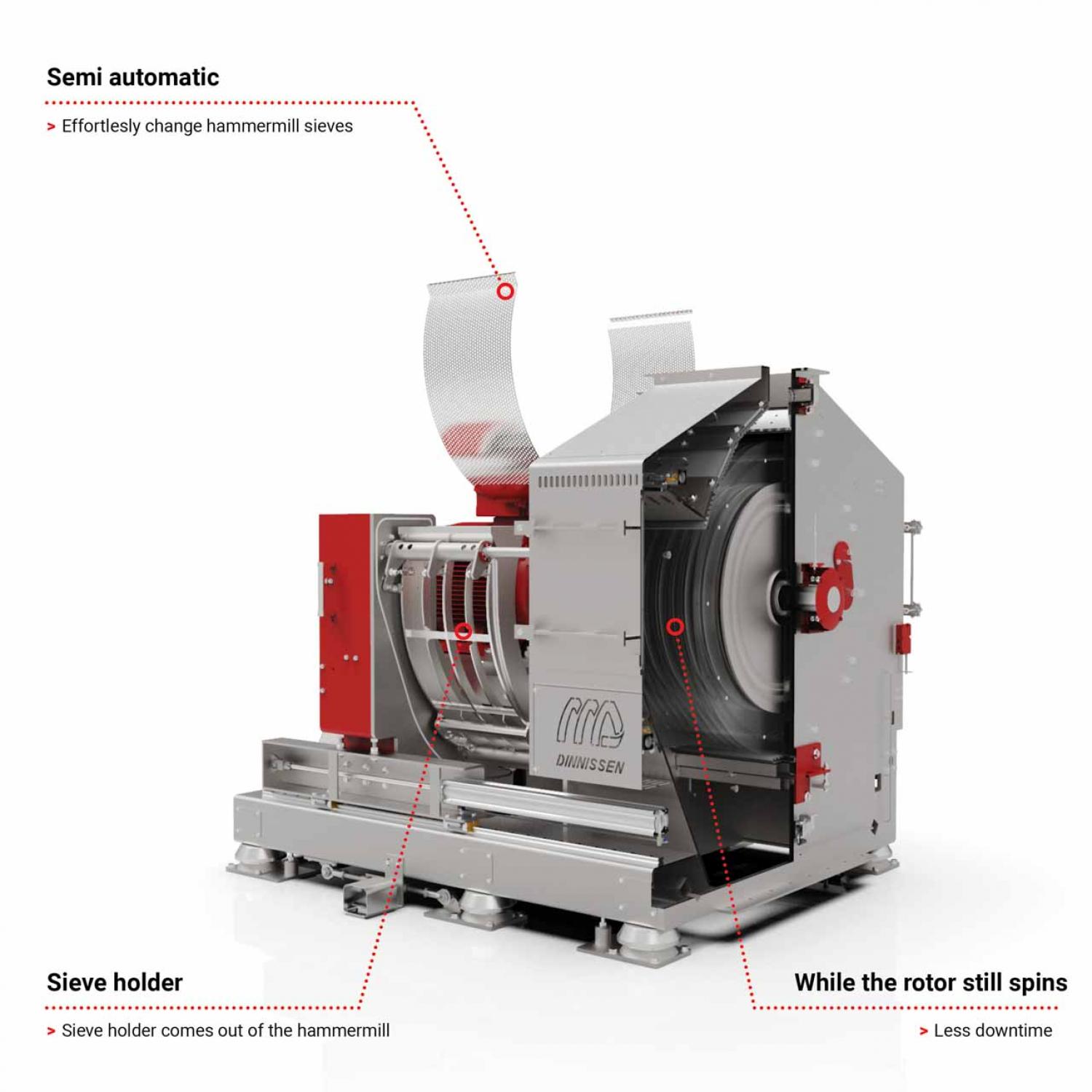

Minimizing Downtime

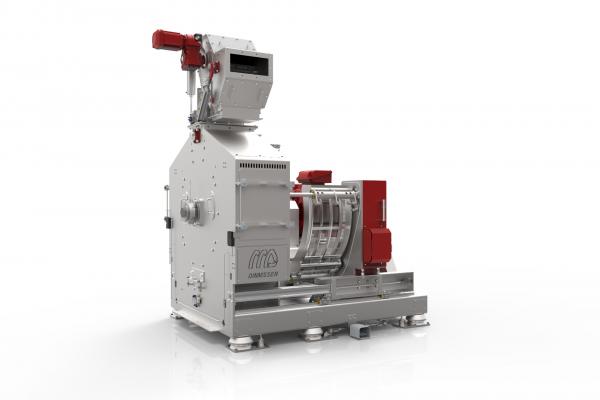

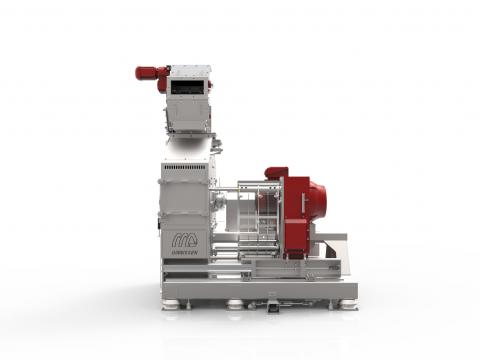

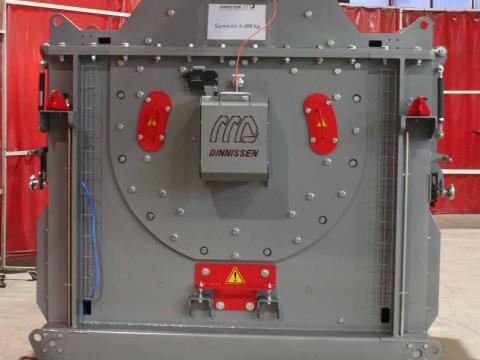

The Hamex® Fast Screen Exchange Hammer Mill allows sifter changes to be made while the rotor is still spinning. This results in ten minutes saved sifter change. In addition, the Hamex® Fast Screen Exchange Hammer Mill is equipped with large inspection hatches that provide quick and easy access for inspection, cleaning, and maintenance.

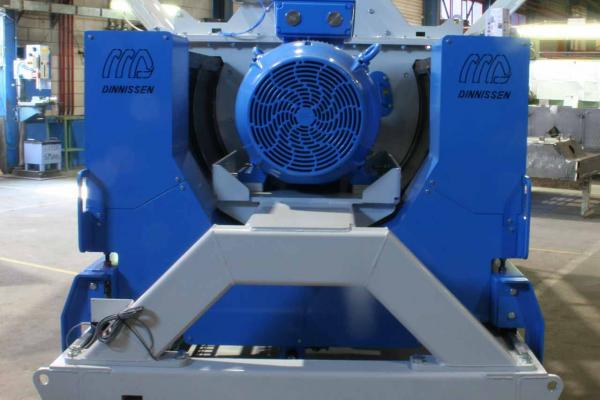

Hamex® Hammer Mills are the result of years of innovation and continuous development to make them even more efficient, productive, reliable, energy-efficient, safe and quiet. All Hamex® Hammer mills are designed as follows:

- Long service life thanks to its proven robust construction

- Good accessibility: wear parts can be replaced quickly

- Variable direction of rotation to spread wear

- Production, quality control, and testing are all carried out in-house

- Optimized over decades for efficiency, capacity, and uptime