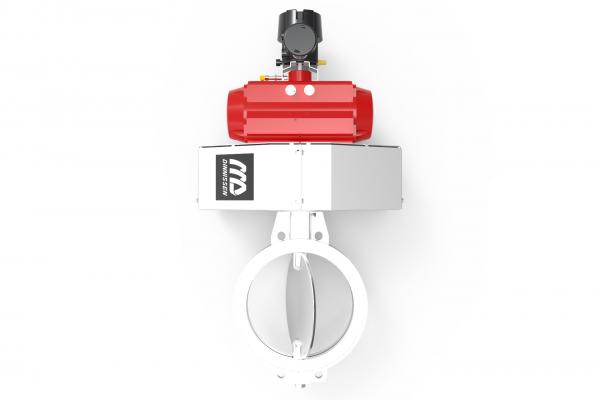

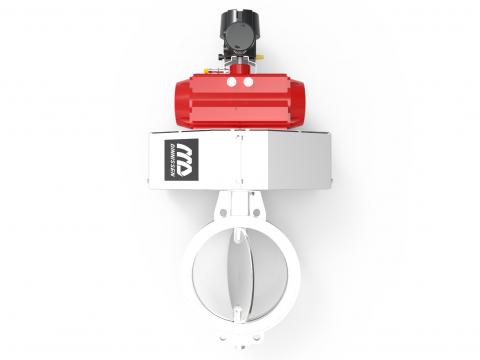

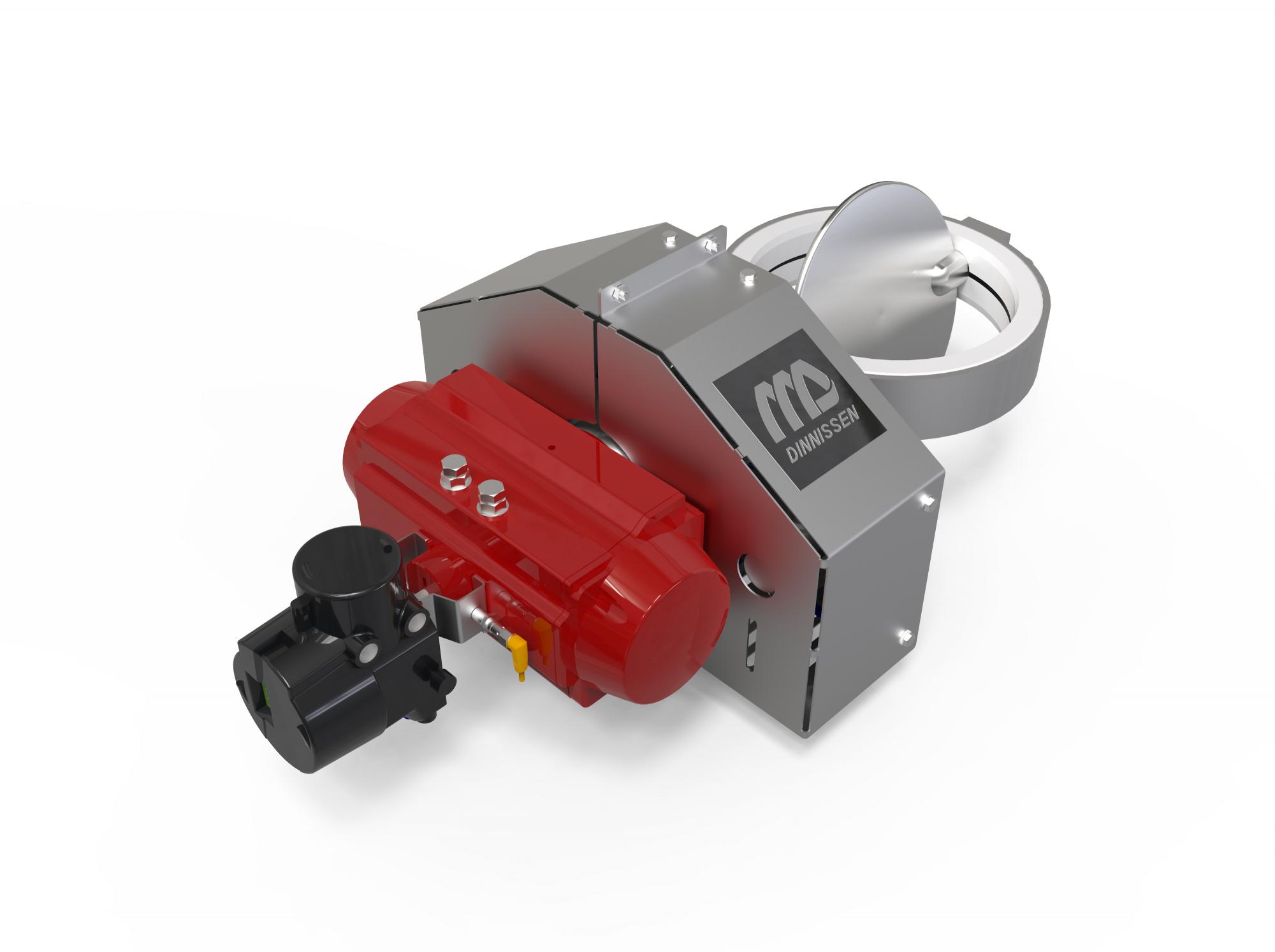

Accurate to the gram

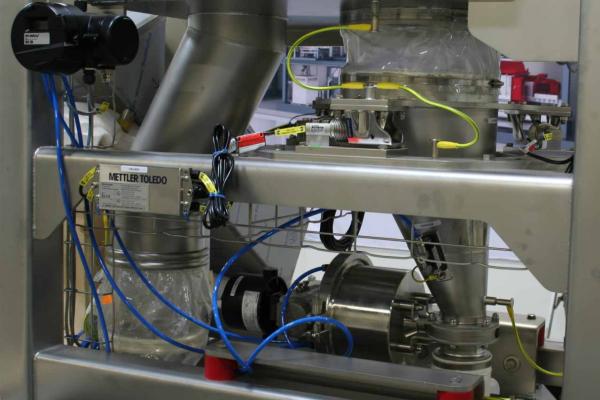

Production requirements in the powder industry are becoming increasingly strict. Whereas initially, a dosing accuracy of 100 grams was sufficient for processing bulk materials, the demand came for a much more accurate dosing system. In response to this demand, our engineering department has developed a Micro Dosing System with an accuracy of 1 gram. The Feeder Valve can be used in a batch weighing application as well as in a continuous weighing application. The system uses hardly any energy, has short dosing times, and is applicable in many sectors. The Dinnissen Feeder Valve has been validated by leading producers of milk powder, cocoa powder, creamers, sugars, whey powders, lactose, premixes, and baby food.

- Very high accuracy, up to the gram

- Suitable for both batch and continuous weighing systems

- Energy efficient

- Short dosing times

- Validated system