Safe emptying and handling

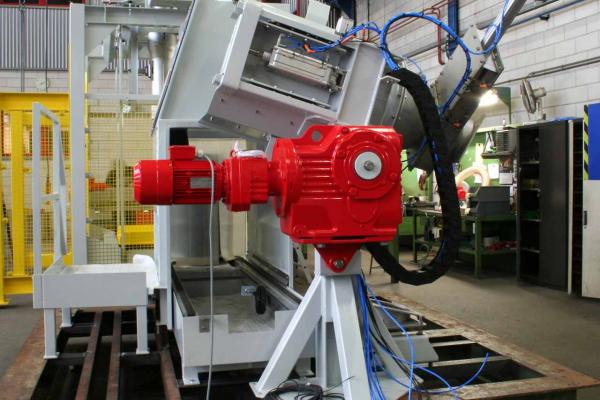

With Dinnissen's drum, container, and barrel handling system you are assured of a safe and dust-free handling system that ensures the complete emptying of both drums and containers. The drum, container, or barrel is connected dust-free. After hermetic connection, the drum, container, or barrel is turned 180 degrees and opened using a tipper. For toxic or hazardous substances, more may be needed than just a hermetic connection. For this purpose, Dinnissen offers the option of emptying drums, containers, and barrels in a completely sealed enclosure. This way, operator safety can be guaranteed, no matter what substance is being handled.

Empty drums or containers can be cleaned and reused, or the choice can be made to shred or flatten the material. This step can also be implemented in the process after the drums or containers have been delivered and emptied. Again, Dinnissen looks for the most cost-effective and environment-friendly option.

- Designed with an eye on operator ergonomics

- Empty drums and containers without residue

- Emptying and processing in one streamlined process

- Various processing options

- Also suitable for toxic substances