Centrifugal Sifters

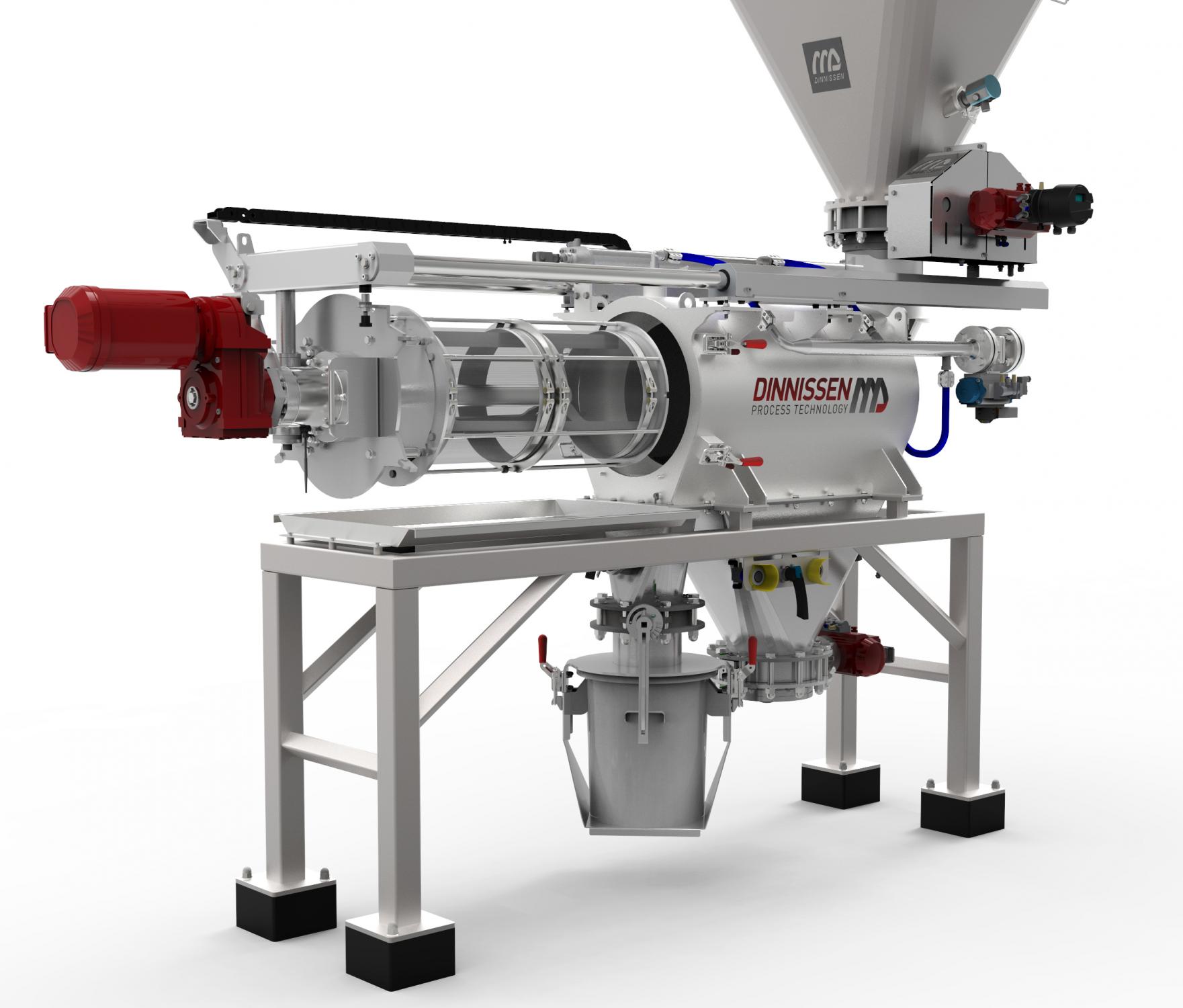

Dinnissen's Centrifugal Sifters make it possible to sift large quantities of product quickly and accurately. The centrifugal force in the rotating, cylindrical sieve ensures that the product is sifted evenly.

Dinnissen's Centrifugal Sifters make it possible to sift large quantities of product quickly and accurately. The centrifugal force in the rotating, cylindrical sieve ensures that the product is sifted evenly.

Process:

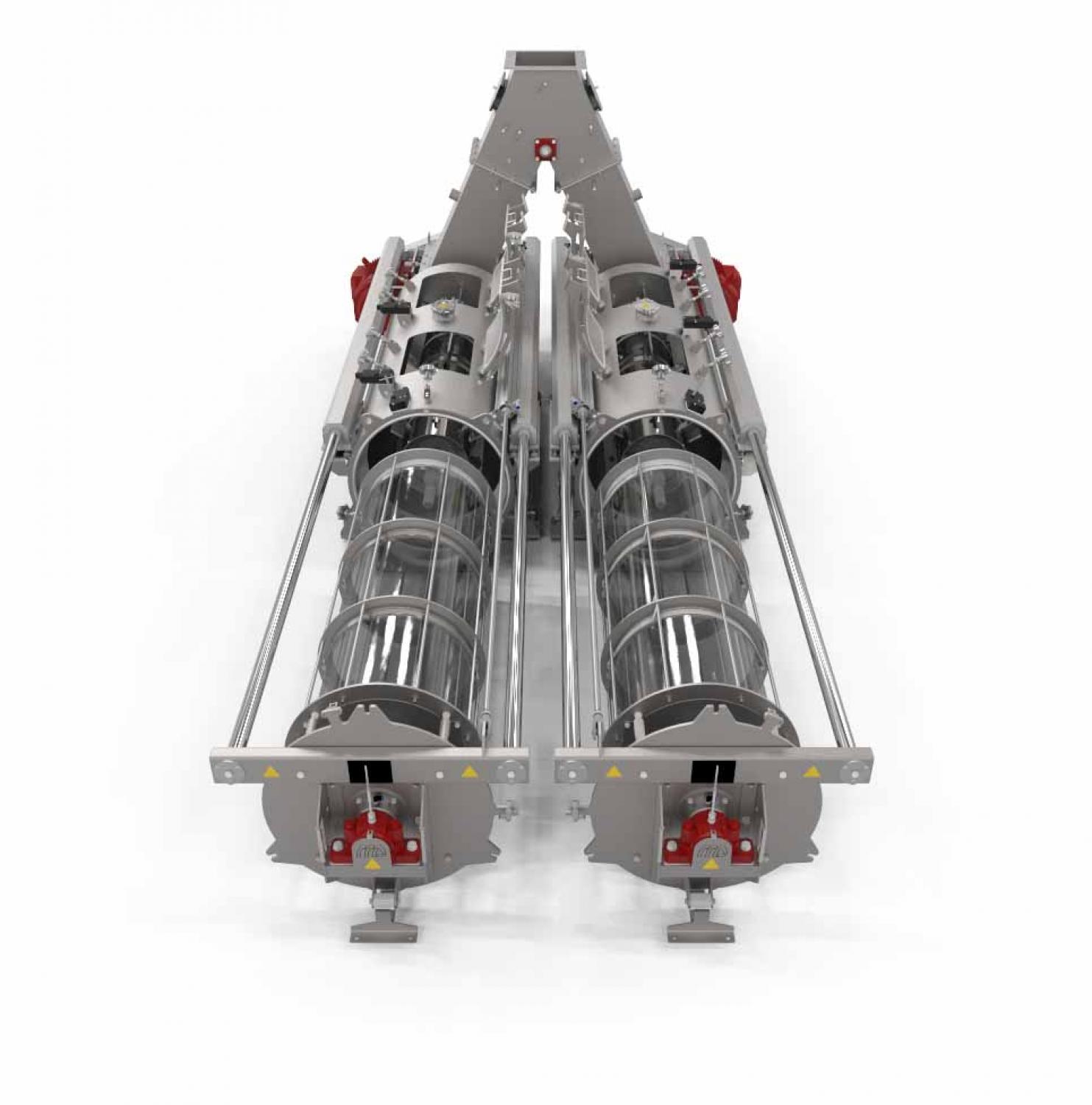

Centrifugal Sifters are ideal for processing varying amounts of product. Thanks to the various setting possibilities and mesh openings between 250 and 2000 µm, different capacities -from a few kilograms per hour up to more than 39 tons per hour- can be processed with a single machine. The centrifugal force in the rotating drum ensures that the product to be sifted is pressed against the perforated drum wall. Only the product particles that are small enough pass through the holes in the drum wall. Depending on the type of product and the required size of the sifting surface, Dinnissen provides a solution that meets the desired capacity and integration into existing systems.

In the feed and food industry, the requirements in the field of safety and hygiene are becoming increasingly strict. The machines used in these industries must also meet high standards. A Centrifugal Sifter from Dinnissen is designed to meet all hygiene and safety requirements within the sector. Centrifugal Sifters, for example, can be supplied with approval for ATEX Zone 20, which means that the sifter can also safely process explosive substances. For example, sifting machines that are integrated within a pneumatic process must meet additional requirements with a design pressure of more than 0.5 bar overpressure. Dinnissen provides a Pressure-Equipment-Directive (PED) inspection and delivers the screening machine with an approved Notified Body certificate.

A Centrifugal Sifter from Dinnissen can process capacities from a few kilograms per hour to more than 30 tons per hour. Dinnissen also offers specific solutions for even larger product quantities. The capacity of the sifter depends, among other things, on the product that is to be sifted and the perforation diameter used for sifting. Mesh sizes can vary between 250 and 2000 µm, but very fine-meshed products of > 75 µm can also be processed by the Centrifugal Sifter.

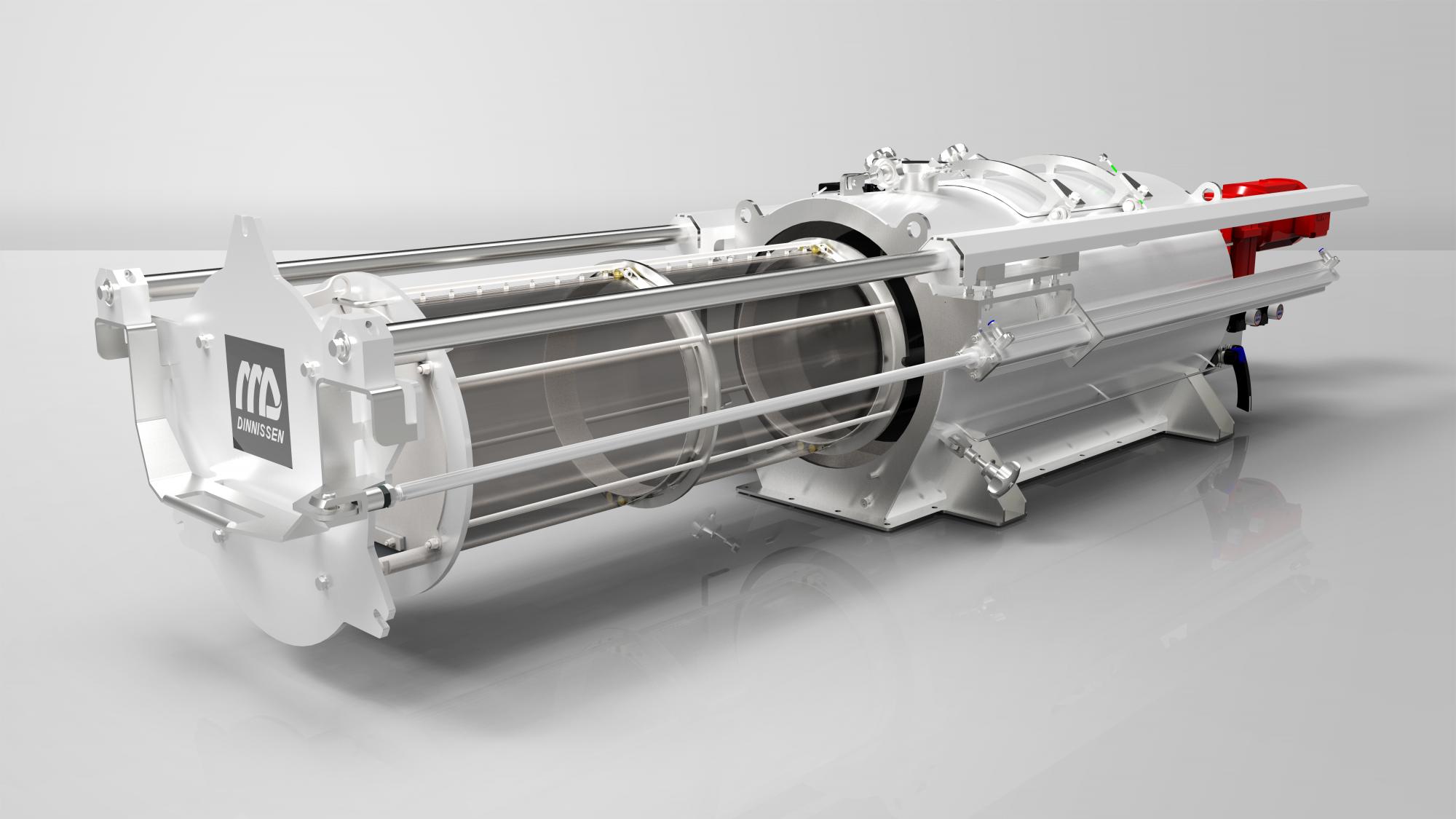

Whether a nylon fabric sifter can be used for sifting the most fine-grained products depends on the product type and the specified requirements. If a nylon fabric sifter does not suffice, a stainless-steel sifter can be chosen. In addition, Dinnissen offers the option of ultrasonic technology. This is a high vibration frequency of the sifter, which - in addition to centrifugal force - contributes to the sifting process.

In a Centrifugal Sifter, there is a cylindrical sieve chamber that rotates on its axis. The product to be sifted enters this sifting chamber via a pneumatic conveying system or by gravity. Once in the sifting room, the product is pressed against the walls of the sifting basket by rotating motion. This principle is called centrifugal force. The walls of the sifting basket have perforation holes through which the product of the desired size can exit. Material and contaminants that are too large remain in the sifting room and are led to a separate exit of the machine. In this way, this residual material can be easily removed from the centrifugal sifter after the sifting process.

The various adjustment options ensure that the Centrifugal Sifter can be used for a wide range of product types, capacities, and environments. Dinnissen has already installed more than 500 Centrifugal Sifters for a variety of applications and therefore has a suitable sifting solution for every demand.

Download our brochure or the datasheet with all options, models and measurements or freely contact one of our experts.

In addition to Centrifugal Sifters, Dinnissen has developed the Wingdoor Sifter, with extra wide opening doors. We also have Vibrating Sifters and Rotating Drum Sifters in-house. We are happy to advise on the best suitable solution, for the desired sifting result.

System integrator Dinnissen optimizes and innovates your production process with tailored solutions: developed, manufactured and tested in-house. From product intake, transport, dosing and weighing, mixing, grinding, sieving and packaging to full automation and control. We maximize the performance and efficiency of your entire process.