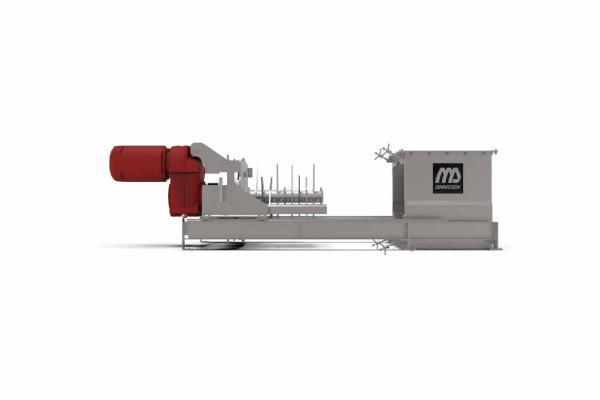

Key features, options, and models

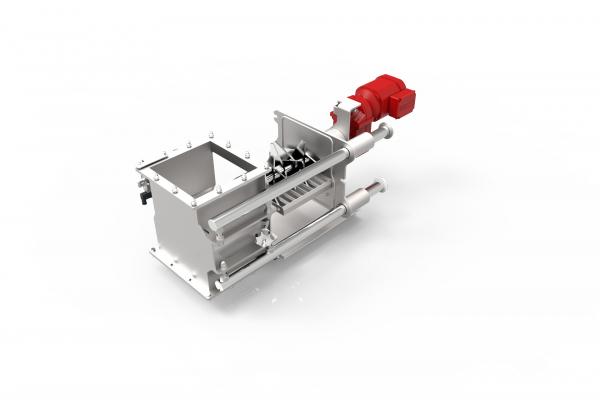

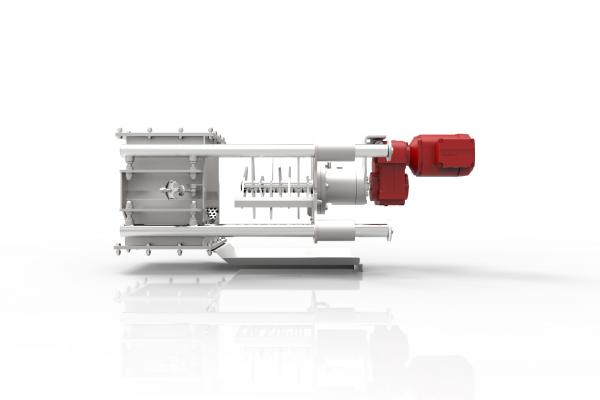

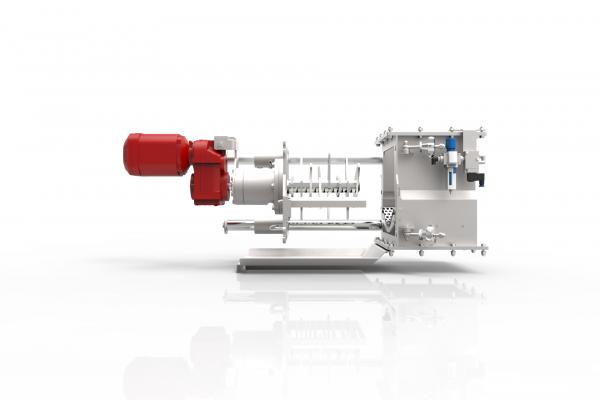

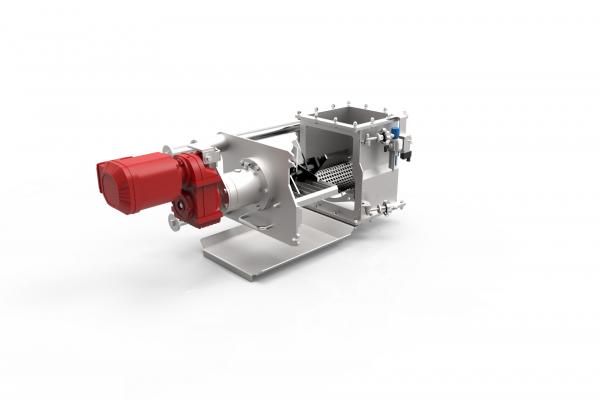

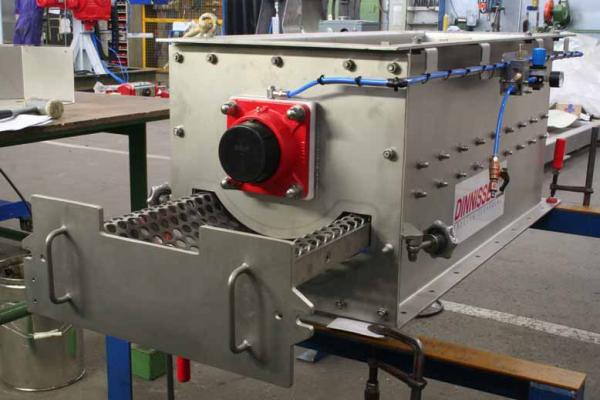

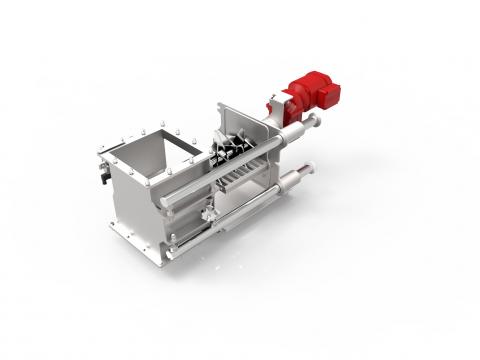

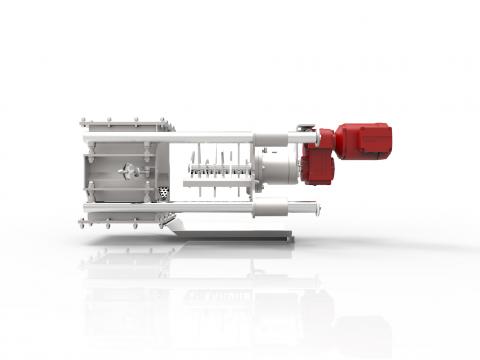

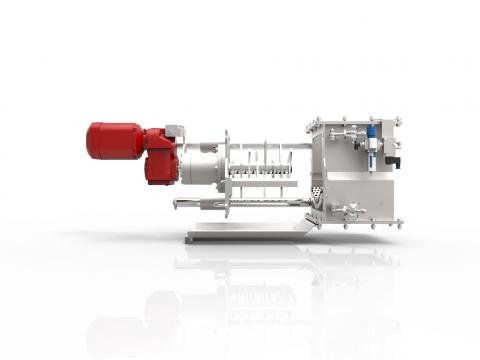

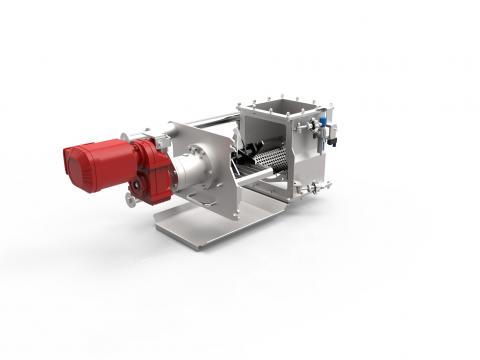

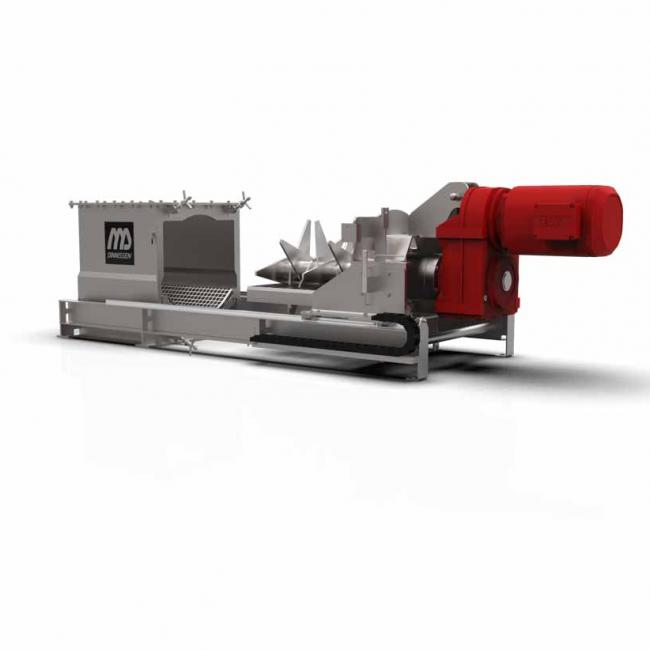

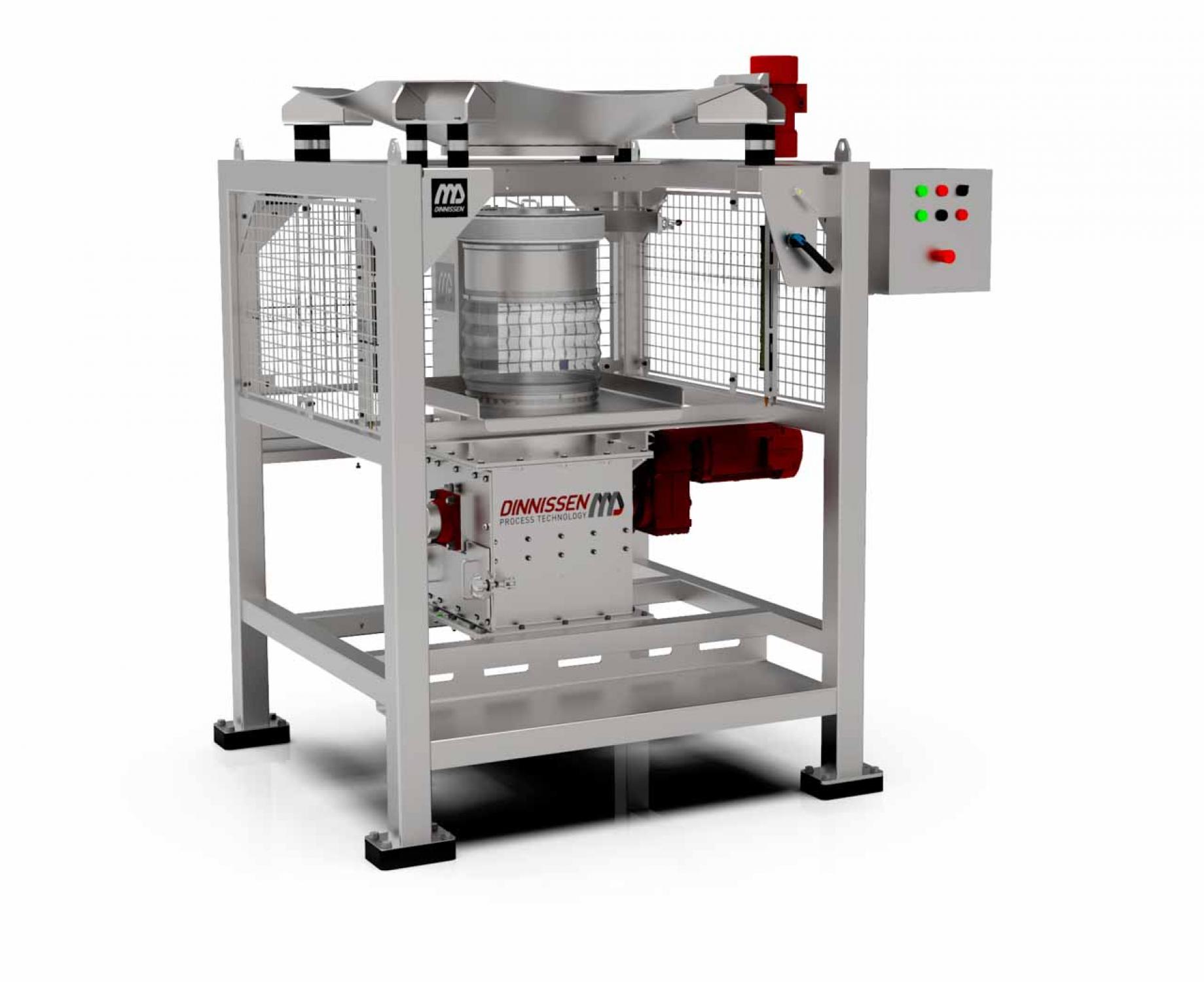

The directly driven machines are extra robust and therefore extremely suitable for breaking soft to medium-hard lumps, clods, and agglomerates. Because of the low heat generation, our breakers are excellent at reducing moist and greasy products, such as cocoa cake, filter cake, and cinnamon sticks. The fineness range is between 10 mm and 150 microns. Depending on the desired final fineness, different rotor versions are available, with capacities up to 80 tons/hour. Of course, this capacity depends on the product and the desired fineness.

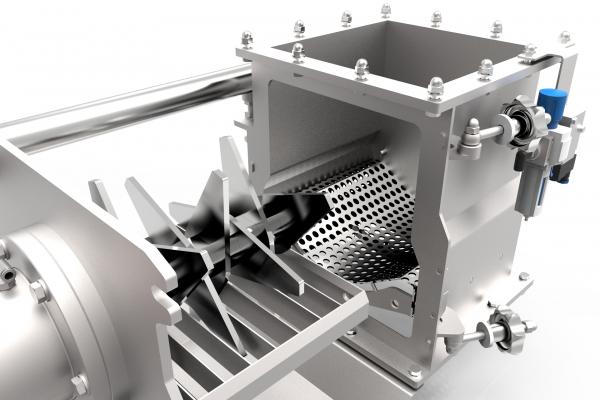

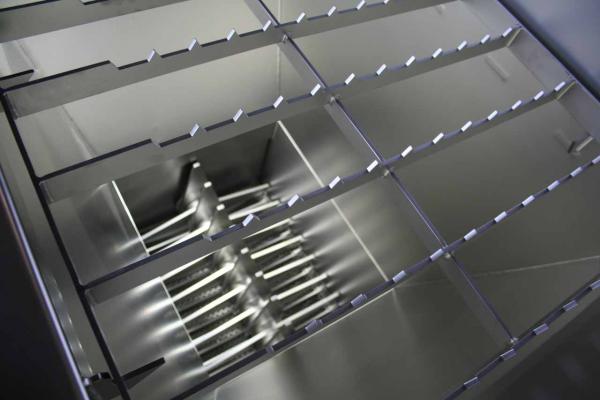

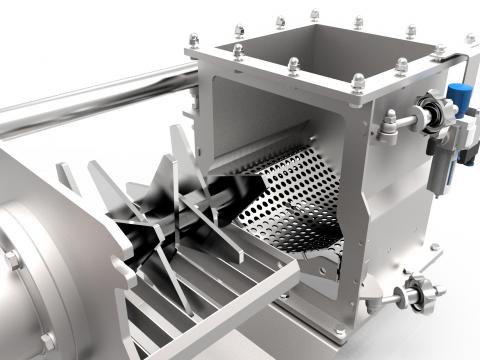

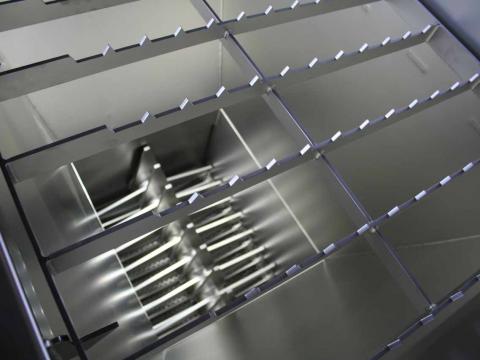

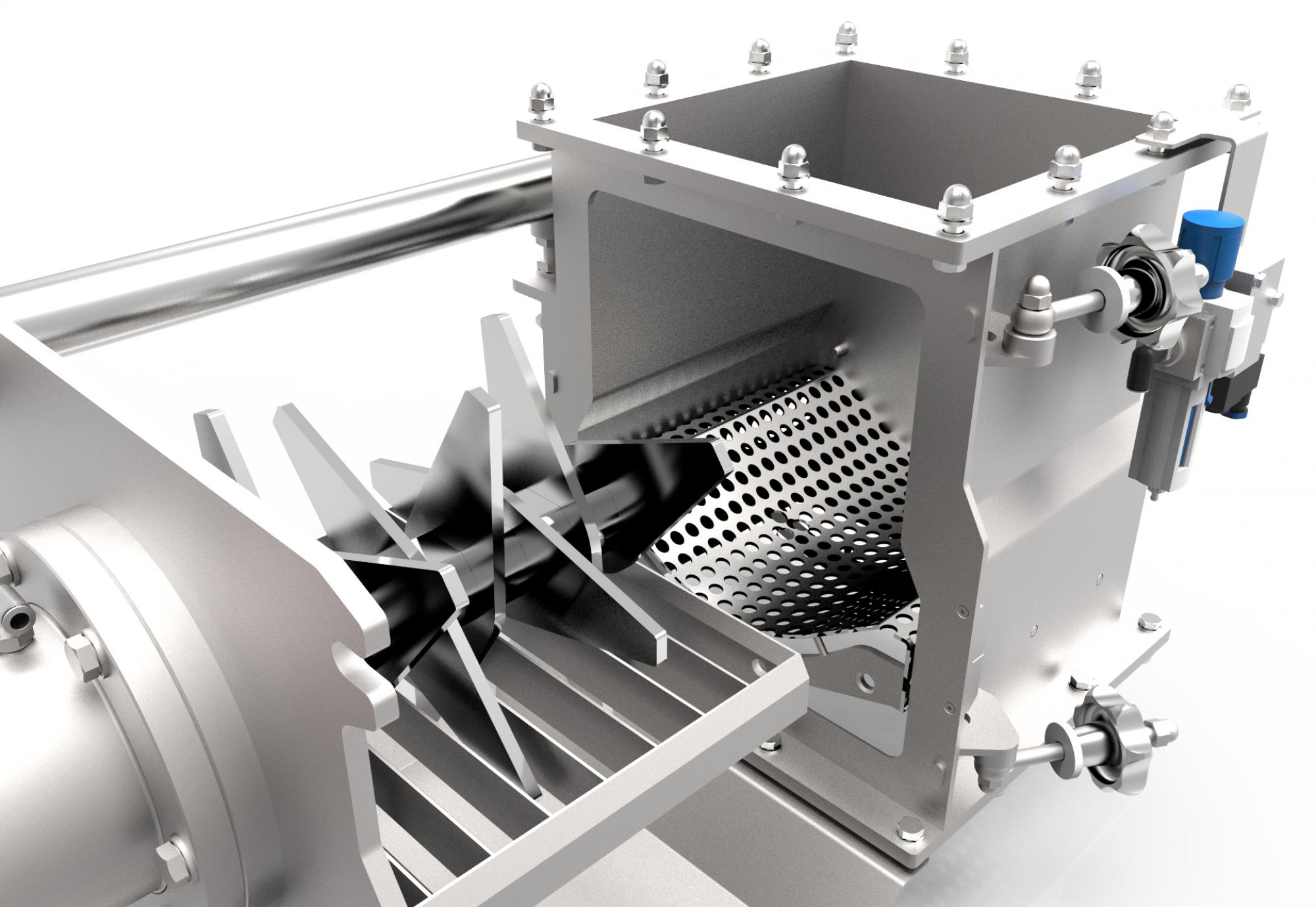

For applications in the fine range, the rotor is placed above a sifting section. The broken/ground material is rotated over the sifter to further reduce the product. The sifting section is optionally removable thanks to an easily accessible sliding drawer. The rotor has no hollow spaces and is mounted on one side, allowing it to be moved out of the housing via a guide rod for easy cleaning and inspection.

Dinnissen shredders are also available as EHEDG versions, optimized for hygiene and food safety. For the food industry and infant food, our shredders are made entirely of stainless steel, including a very high-quality finish.