Modular build

Depending on the product and the production process, several options can be added to the base of the Big Bag Filling Station. When processing very light products such as silicas or expanded perlite, vibration can stabilize the Big Bag and compact the product (this allows more kilos in one Big Bag). Different types of vibrations can be used and for unstable Big Bags, various testing possibilities are available. Furthermore, Dinnissen develops systems with a hygienic design. This includes minimal horizontal surface area, open profiles, components that are accessible for cleaning, choice of materials, and finishing.

For low capacities, Big Bags can be hung from static hooks. To be able to process a higher number of Big Bags per hour while keeping ergonomics in mind, automatic moving hooks are optional. The hook suspension points are moved towards the operator so he or she is able to hang the Big Bags on the suspension hooks without having to lean forward. After filling, the hooks automatically release the Big Bags.

If desired, a Big Bag ventilation system can also be chosen, in which the Big Bag is connected dust-free to an inflatable cuff and automatically unfolded and blown into shape before filling. With a venting system, the Big Bag can be vented with negative pressure after the filling process to avoid dust formation. Big Bags with flammable substances can be vacuumed, after which nitrogen is injected so the product can be stored atmospherically, in a protected environment. Another option is sealing the Big Bag.

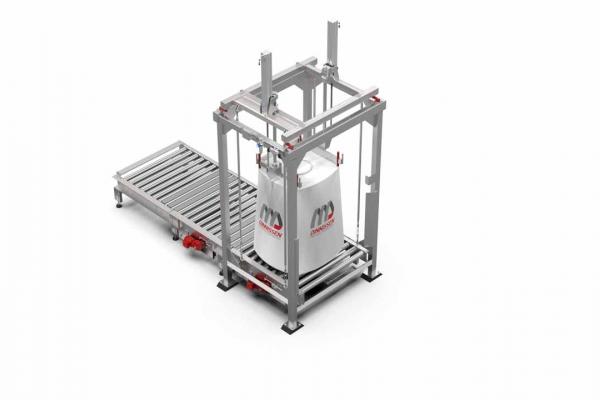

When working with different-sized Big Bags, height adjustment can be added to the system. This can be done with an industrial design, as well as a hygienic solution for high-care environments (without hydraulics/hydraulic oil). Big Bags can be discharged with a forklift, roller conveyor, or hygienic belt. We provide low to high-capacity filling systems, that can process up to 45 tons per hour.

- Stabilization and compacting by vibration

- Various possibilities for hygienic design

- Aeration or de-aeration system

- Vacuum and sealing options

- Height adjustment possible

Read how this Big Bag Filling System was implemented in the high-care mixing lines of DSM's new production facility in Poland.