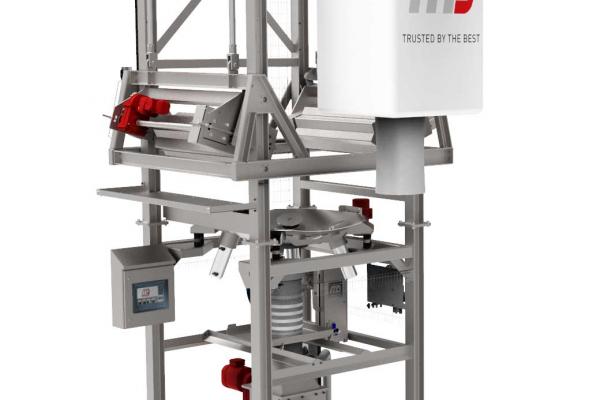

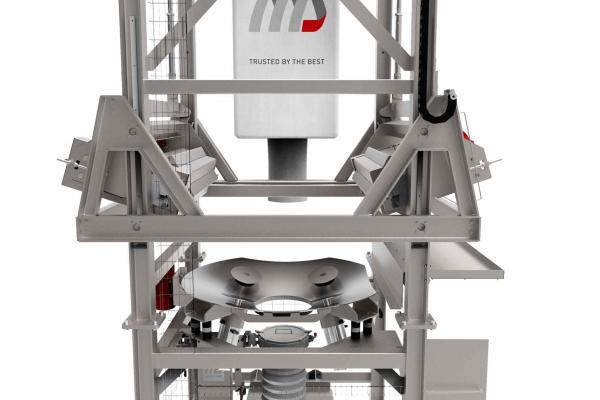

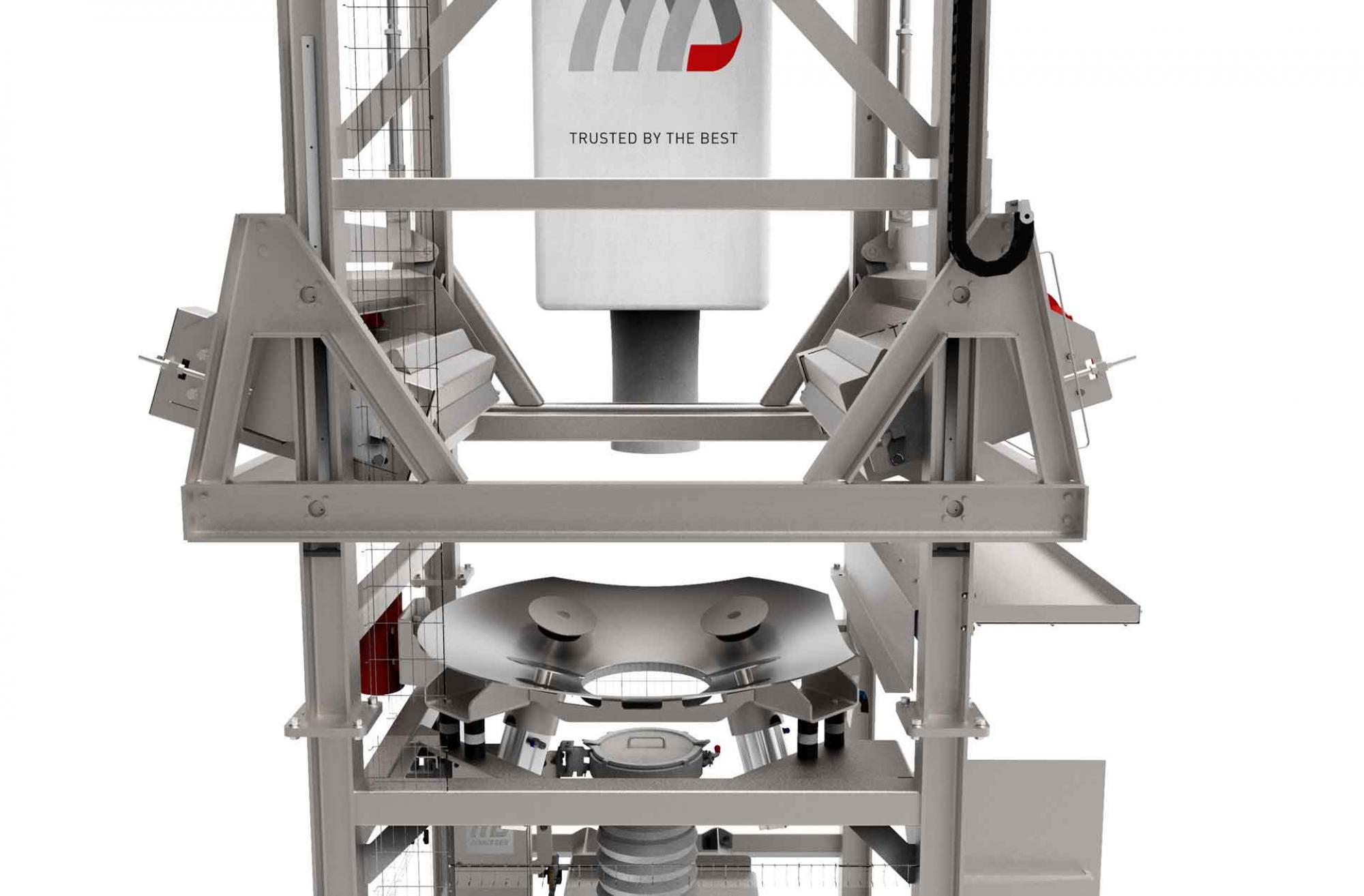

Big Bag Emptying Station

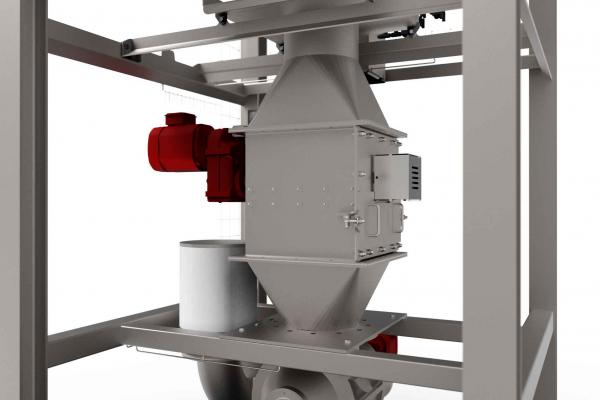

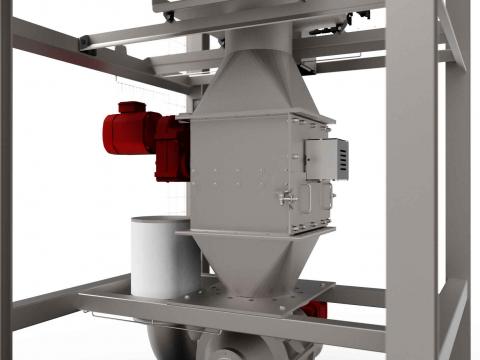

For many manufacturers, emptying Big Bags is a difficult and time-consuming process. The Big Bag Conditioner makes this a thing of the past. The system first loosens highly compacted products in the Big Bags, after which the Big Bags can be emptied smoothly and quickly.