Customer Story: Südstärke

Customer Story: Südstärke

Südstärke and Dinnissen: partnership in innovation and reliability

Since 1981, the facilities in Sünching and Schrobenhausen have together formed the company Südstärke. However, the history of this potato starch manufacturer dates back much further. A vegetable drying plant was founded in Sünching as early as 1916. In 1938, a potato flake producer opened in Schrobenhausen. In 1947, both companies started producing potato starch. The collaboration between the organizations intensified over the years, and from 1981, they continued as one company: Südstärke GmbH.

A leader in potato starch production

Annually, around 600,000 tons of potatoes are processed, resulting in 150,000 tons of starch. Südstärke distributes its high-quality starch to various sectors. 50% of the production goes to the food industry, and 50% is used in other markets such as the paper industry, chemical industry, and animal feed. At the Schrobenhausen facility, all starch is modified to give it the specifications to meet various industrial demands.

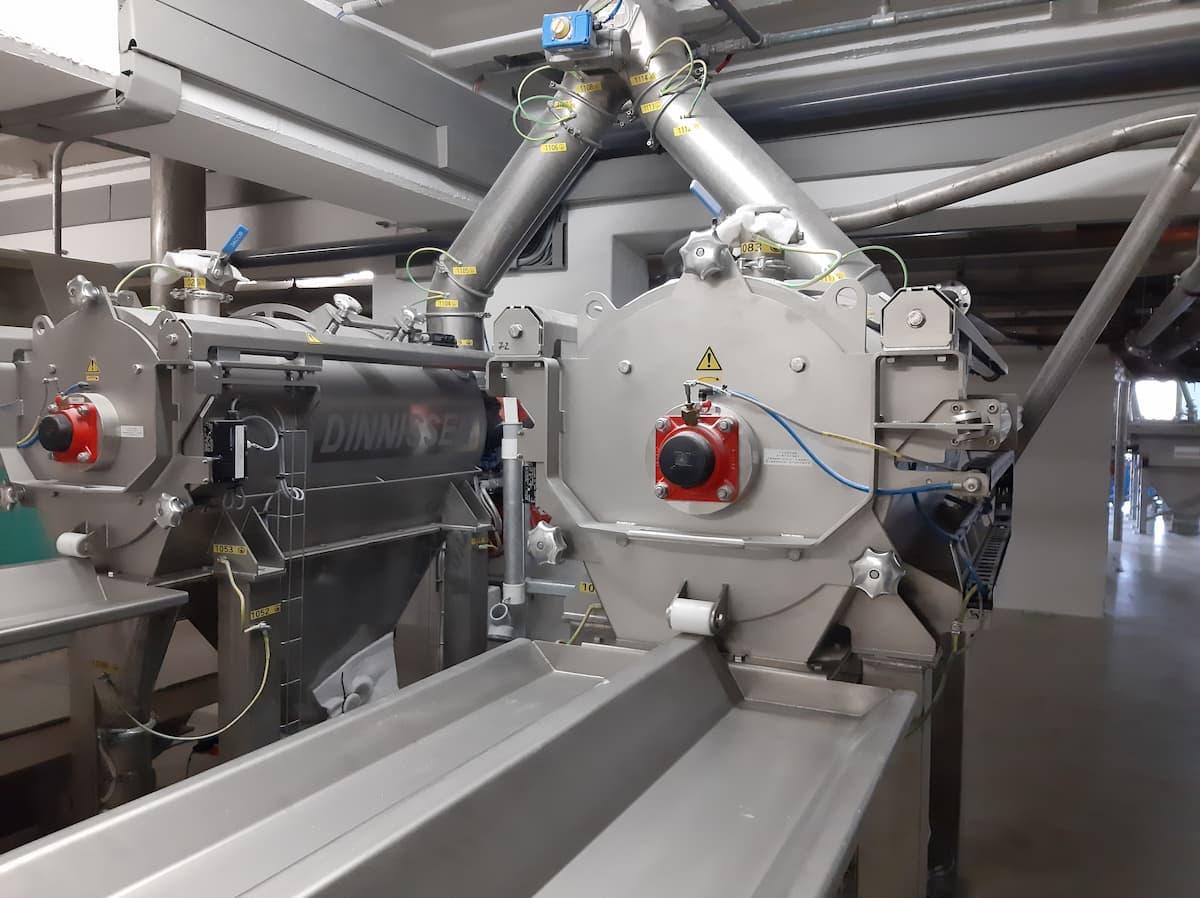

Centrifugal Sifters at Südstärke.

"The ease and safety with which the sieve basket can be changed were decisive factors in our choice for a Dinnissen sifting machine."

MR. Kreuzer, COMPANY manager AT Südstärke

Why Südstärke chose Dinnissen

Südstärke Schrobenhausen was in search of sifting machines capable of handling potato starch with varying moisture percentages. Their colleagues at the Sünching location had a Dinnissen sifting machine and were very satisfied with its performance. That is how the team from Schrobenhausen ended up with Dinnissen for their sieving installation. Mr. Kreuzer, company manager at Südstärke, explains: "The ease and safety with which the sieve basket can be changed were decisive factors in our choice for a Dinnissen sifting machine."

The start of the process

Before a sifting machine was installed in Schrobenhausen, Dinnissen conducted several rounds of testing with Südstärke's product at the D-Innocenter test center. Test were done with potato starch with varying moisture percentages. In this way, the sifting solution could be tailored precisely to Südstärke's production process. The tests concluded that the starch could be processed successfully, with 500 and 1000 mu (μ) sifting mesh.

Centrifugal Sifter at Südstärke.

"Dinnissen supported us well in commissioning the installation and has the know-how to advise us in the best possible way."

MR. Kreuzer, COMPANY manager AT Südstärke

Centrifugal Sifters at Südstärke.

Further cooperation

The collaboration between Südstärke and Dinnissen is very good, even though there were challenges along the way. Following the installation of the sifting systems, Dinnissen also dispatched a mixer to Schrobenhausen. However, this machine could not be put into operation as initially expected. It took some time before everything was arranged and working properly. “However,” Mr. Kreuzer explains, “we had frequent contact and ultimately brought the project to a successful conclusion together. Dinnissen supported us well in commissioning the installation and has the know-how to advise us in the best possible way.”

Capacity

Currently, four CZ6- and two CZ4-centrifugal sifting machines are operating at Südstärke in Schrobenhausen, with several more sifting machines at the Sünching location. The capacity of these machines depends on the starch's moisture percentage, ranging from 8 tons per hour (with 20% moisture) to 12 tons per hour (with 9% moisture). With a bulk density of 0.75, these are substantial volumes of potato starch. In addition, downtime is minimized due to the simplicity and speed with which the sieve basket can be inspected and replaced.

"The contact with Dinnissen is always very pleasant. They are committed and collaborative, to achieve the best result together."

MR. Kreuzer, COMPANY manager AT Südstärke

Shared core values

In terms of mentality and core values, Südstärke and Dinnissen are an excellent match. Mr. Kreuzer states: “The contact with Dinnissen is always very pleasant. They are committed and collaborative, to achieve the best result together.” Both Südstärke and Dinnissen hold reliability and innovation in high regard, creating a perfect partnership to achieve solid results using the latest techniques. For instance, Südstärke recently rented a Pegasus® Mixer for batch testing of starch with liquids. Here's to a bright future together.

Do you have a question about your process challenge?

- 75 years of experience in your sector as a system integrator

- Everything in-house: engineering, production, testing, installation, control, and service

- Always a tailor-made solution, for your complete process