Customer Story: Olam Agri

Customer Story: Olam Agri

How Olam Agri produces superior feed with vacuum coaters

Dinnissen has been working together with many producers for decades. We are proud to be able to welcome new customers as well. One of them is Olam Agri, part of Olam Group. This Nigeria-based company realized two production facilities for poultry feed and one for aqua feed 2016. In this article, Arnold Balledux - technical director at Olam Agri - explains the company’s choice to invest in Dinnissen vacuum coaters.

But first, what is vacuum coating?

Vacuum coating technology can be used to add value to your products. This technique allows producers in feed, aqua feed, and pet food industries to drastically improve the quality and properties of their products. This is accomplished by adding functional additives such as enzymes, vitamins, and medicines, at the end of the process line. By using vacuum coating technology, these additives infiltrate into the entire pellet homogeneously. This ensures better, more nutritious feed, as well as healthier animals and a better environment.

"WE CHOSE TO WORK WITH DINNISSEN BECAUSE THEY SUPPLY HIGH QUALITY VACUUM COATERS THAT FIT EXACTLY WITHIN OUR PRODUCTION LINES."

Olam Agri on the collaboration

"After working in Africa for almost 18 years, I now finally have the opportunity to work with Dinnissen machines. Ever since the beginning of my career, I have been charmed by Dinnissen's work. I knew the company from trade fairs, and I always wanted to work together with them. That's why I am proud to have decided to invest in vacuum and fat coaters from Dinnissen at Olam Agri."

Homogeneously distributed coating

"We chose to work with Dinnissen because they supply high-quality vacuum coaters that fit within our production lines perfectly. The amount of coating we use in our production processes is low by percentage. As a result, with previous coating machines, we noticed color differences in our product; the product failed to reflect the desired quality and uniformity. The vacuum coater from Dinnissen solved this problem. Every percent of the coating is distributed homogeneously. Our product is non-leaching, and it looks excellent in terms of quality."

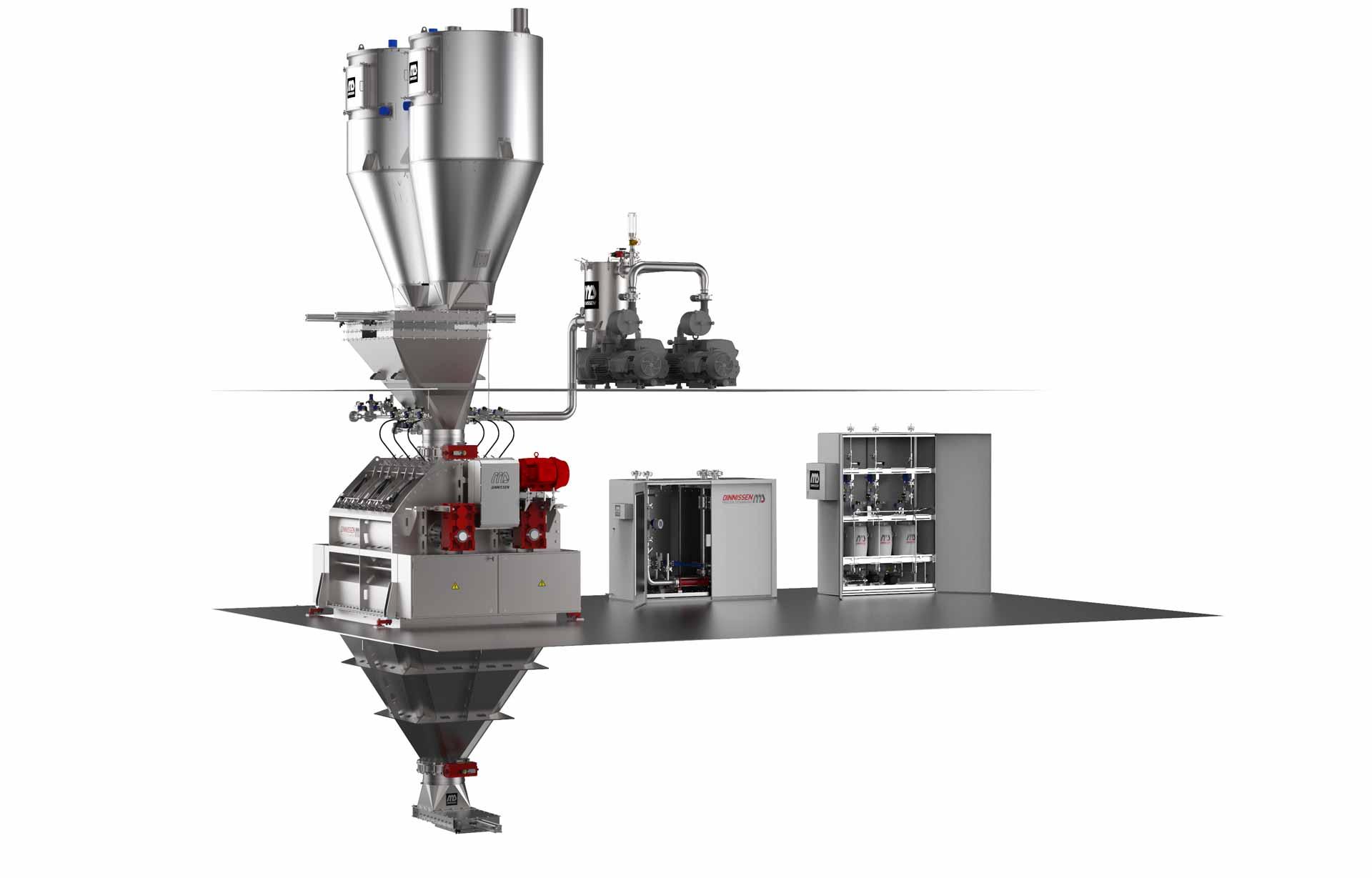

Vacuum coating installation at Olam Agri's plant in Nigeria.

"Every percent of the coating is distributed homogeneously. Our product is non-leaching, and it looks excellent in terms of quality."

Arnold Balledux

Global Technical Head Animal Feeds

Vice-president Animal Feed & Protein-Olam Agri

Olam International Limited

SOLUTIONS IN CHALLENGING CIRCUMSTANCES

"Dinnissen always thinks along and searches for solutions. A good example of this is the integration with existing automation. That wasn't easy. We have power cuts regularly in Africa, which can lead to problems in the process. Together with Dinnissen, we’ve created a functional solution; during power outages, an auxiliary power unit now keeps our line in full operation.

Working in the process industry in Nigeria is challenging. There is always something going on. This must have been a learning process for Dinnissen as well. Nonetheless, they delivered a complete package and got it up and running in the right way. The people at Dinnissen stand by what they guarantee, and they do not run away from their responsibilities.

Dinnissen makes sure everything is well organized and documented. Materials are delivered correctly and on time. And unlike some other firms, the people at Dinnissen always listen to their customers and think along with them. For example, we have had several constructive meetings with their software department.

We have considered several companies, but the high quality of the Dinnissen machines and the expertise and commitment of the employees were the deciding factors for us."

Arnold Balledux

Olam International Limited

hOW FISH PRODUCERS PRODUCE ENERGY-RICH, NON-LEACHing AQUA FEED

It is important that fish get sufficient oils and fats, without these substances polluting the water. With the Vacuum Coater, the required substances are easily incorporated into the feed. A top layer of, for example, solidified fat can then be applied. As a result, a pellet contains all the "wet" substances a fish needs, without the pellet falling apart when it hits the water. The top layer causes the pellet to sink and be easily eaten by the fish. It is also possible to add a top layer that actually prevents the pellet from sinking. The best possible aquafeed can be produced with vacuum coating technology.

how vacuum coating works in 6 steps:

- The pellets are dosed in a vacuum coater under atmospheric conditions

- Next, a vacuum is created

- After this, oils and liquids -in the exact desired quantities- are sprayed onto the pellets

- Then, the vacuum is broken, allowing the incoming air to push the additives deep into the core of the pellets

- In this way, producers can add up to 80% more functional additives, such as lipids and pharmaceuticals, without losing product

- Finally, additional layers of top coatings, such as sealers, can be applied to each pellet

The result? Strong, high-energy, non-leaching pellets. For better growing, healthier fish, and for less water pollution and feed waste.

Would you like to know how you can optimize your recipe with a Pegasus® Vacuum Coating System? Please feel free to contact us.

3D visualization of Olam Agri's vacuum coating installation.

VIDEO: How VACUUM COATING FOR AQUAFEED WORKS

Do you have a question about your process challenge?

- 75 years of experience in your sector as a system integrator

- Everything in-house: engineering, production, testing, installation, control, and service

- Always a tailor-made solution, for your complete process