Dairy

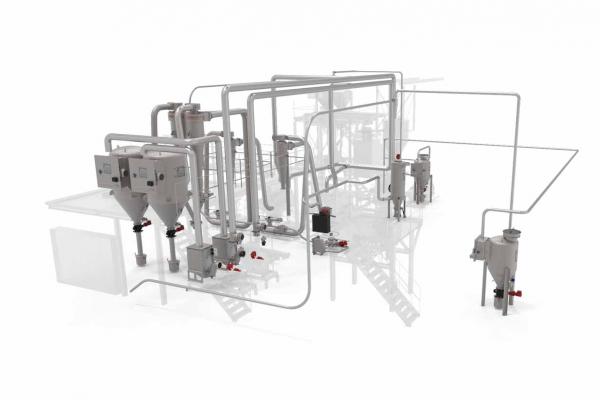

The processing techniques of dairy products differ strongly per manufacturer and per continent. Our dairy experts know how best to design, build and integrate the various processes. To prevent contamination and product damage our solutions are streamlined and hygienically designed.