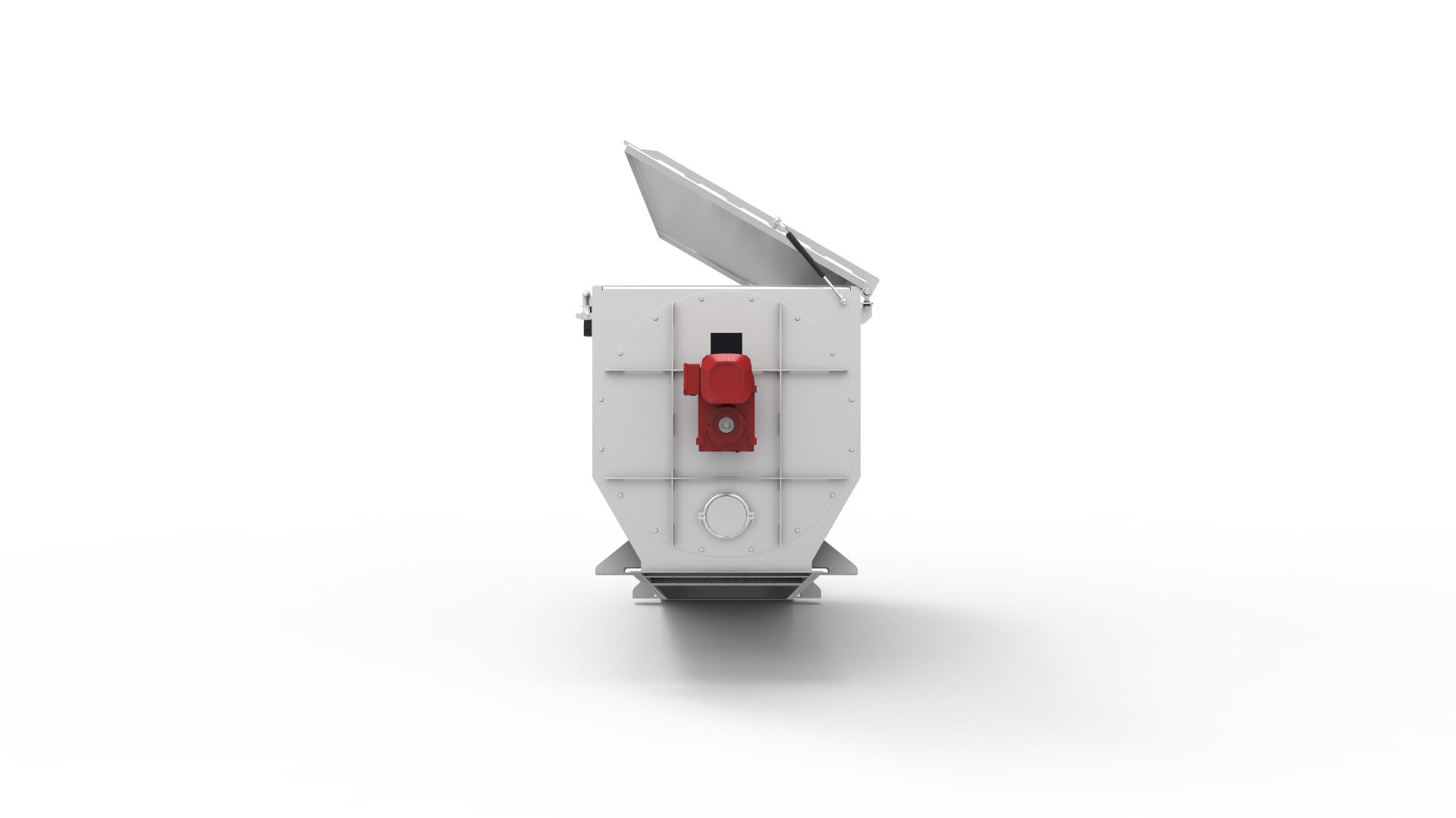

Suitable for processing animal feed - Different perforation sizes - ATEX guidelines

Whereas mainly powders are processed in a centrifugal sifting machine, this rotary version is suited to sifting granular materials and chunks. That is why this type of machine is frequently used in animal feed processing.

During the process, the screen drum rotates at a relatively low speed, less than 1 m/sec. On the one hand, this is to prevent product damage and on the other it is for conformity with the applicable ATEX guidelines. If desired, we supply the screen mesh with different perforation sizes, to allow processing the widest range of products possible. This allows, for example, separation of the finest product particles in the first part of the screen drum in order to collect the desired product at the correct size in the second part of the screen drum. Larger chunks are removed through a separate outlet and returned to the process.

Would you like to know how the Dinnissen rotary sifting machine could add value for your process? Feel free to contact one of our specialists by sending an email to [email protected] or calling +31774673555, without any obligation.