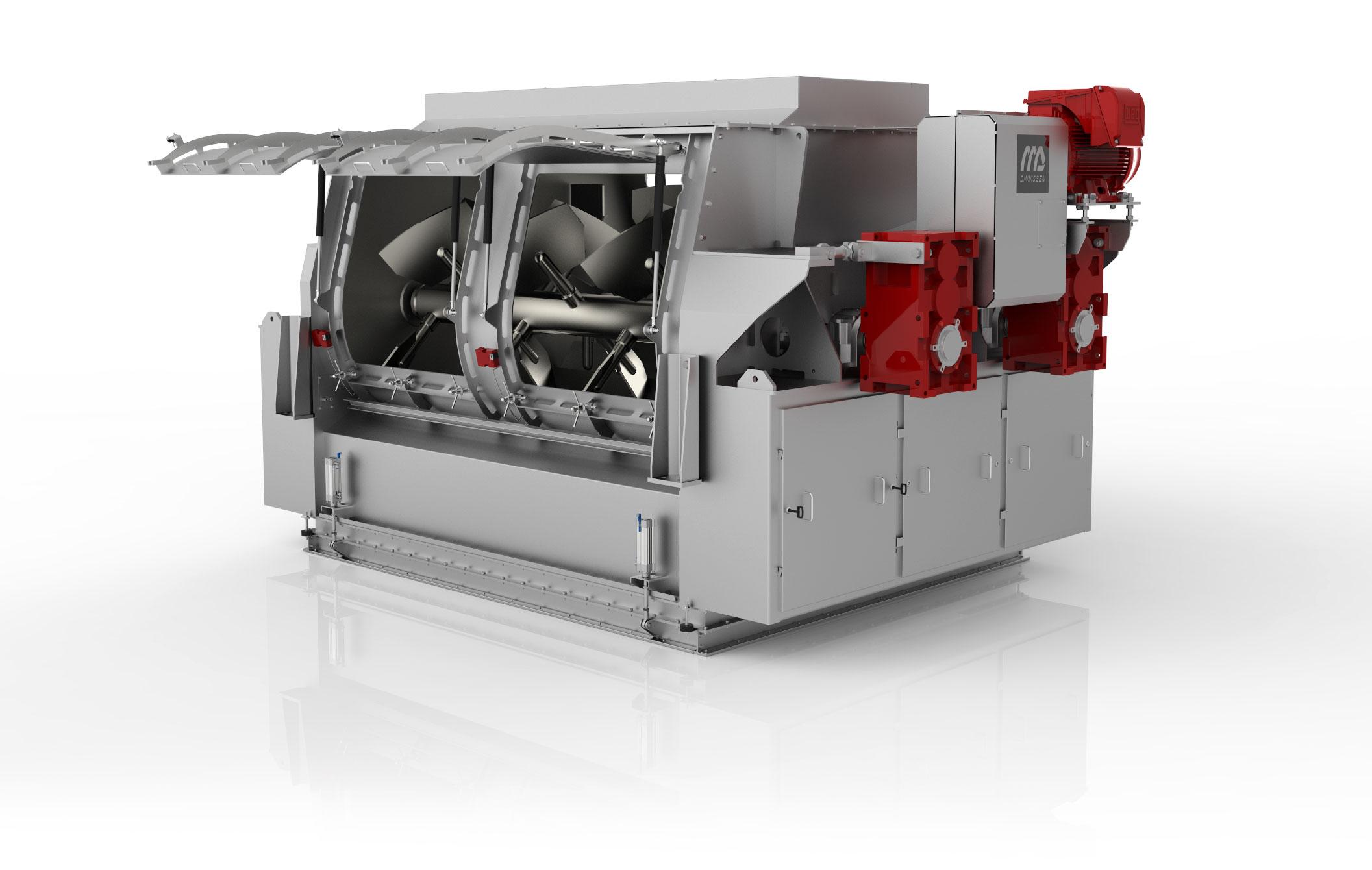

Double axis - Homogeneous mixing thanks to dosing system - Suitable for sensitive products - Fast cleaning

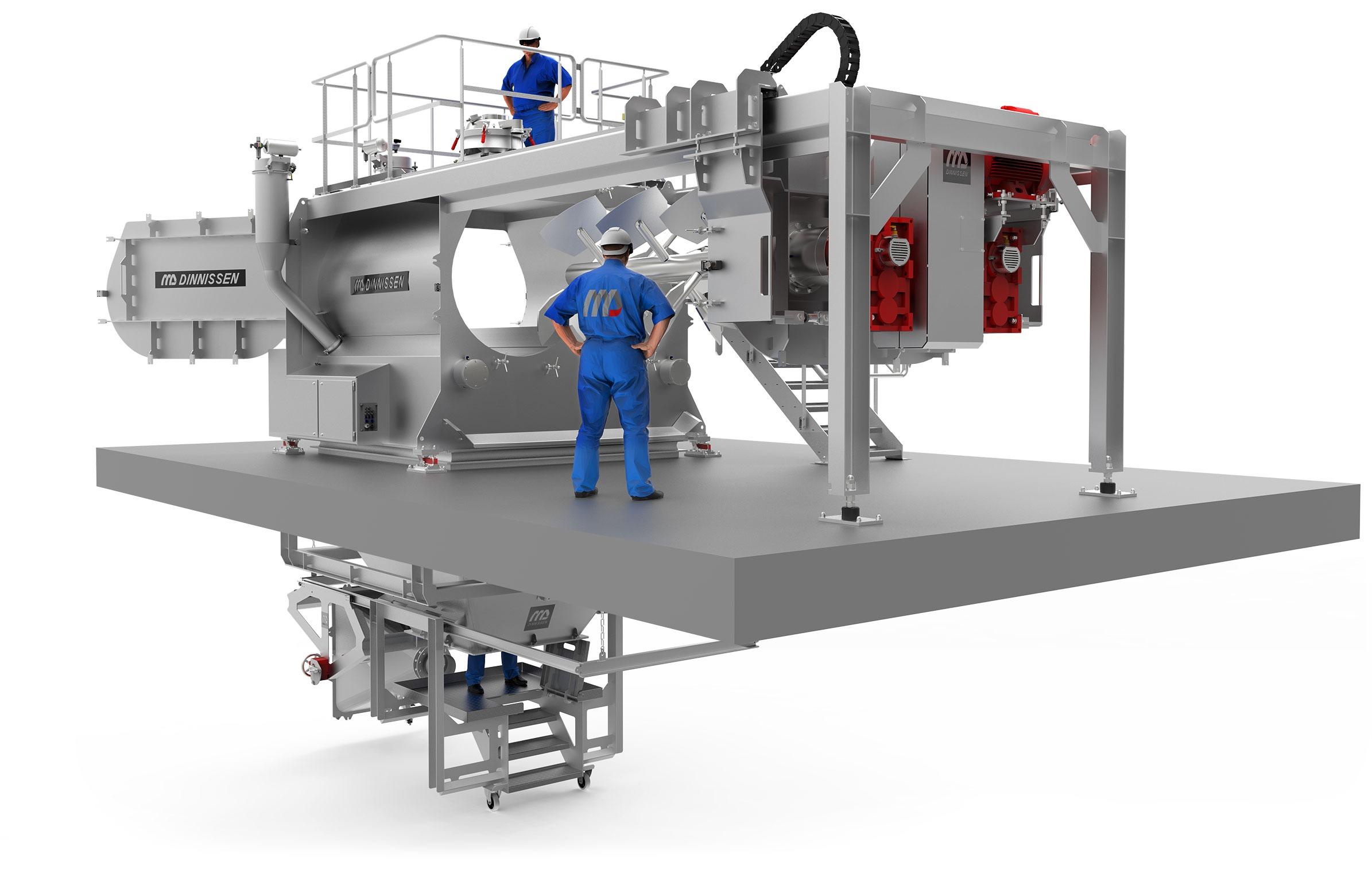

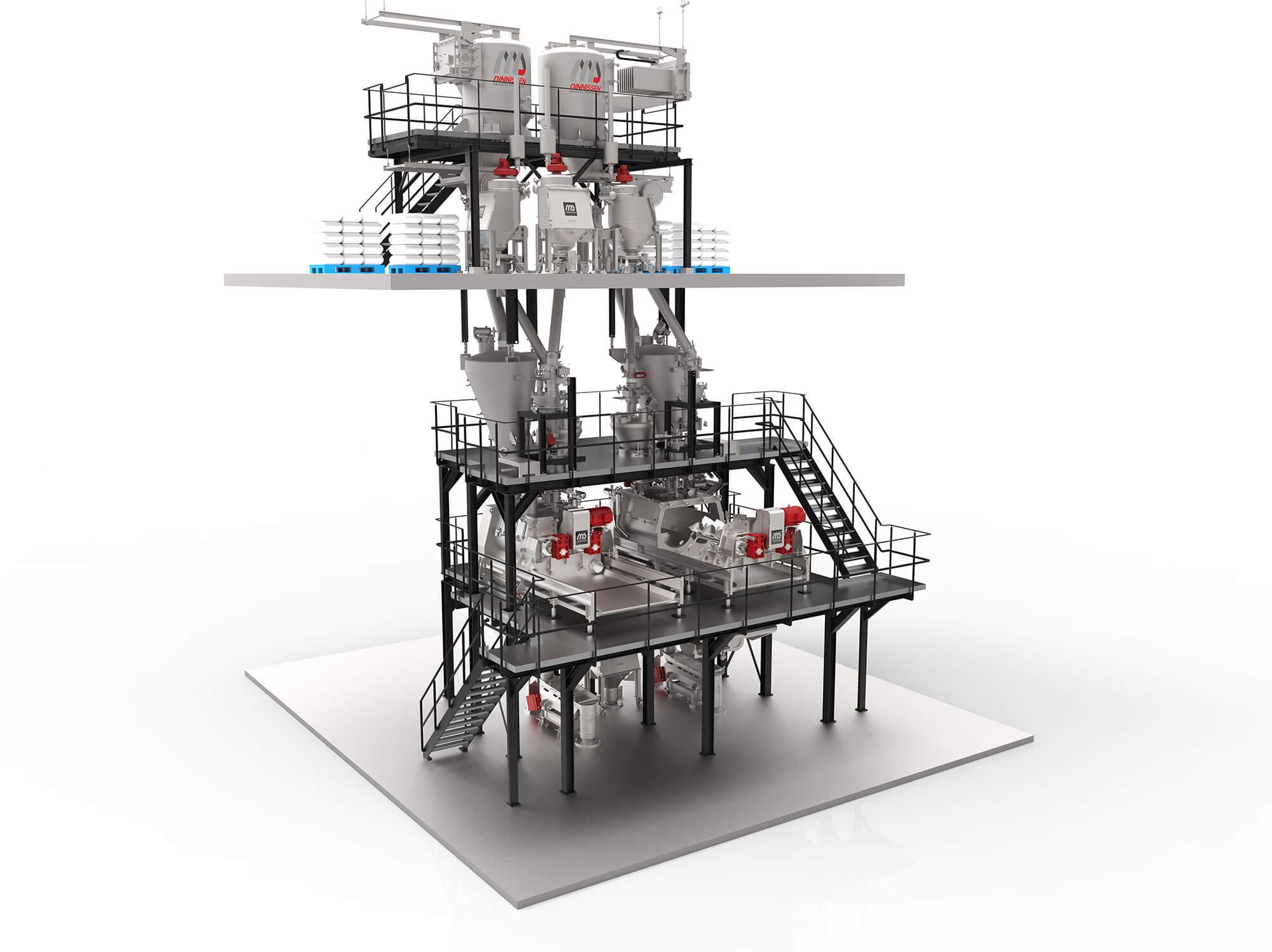

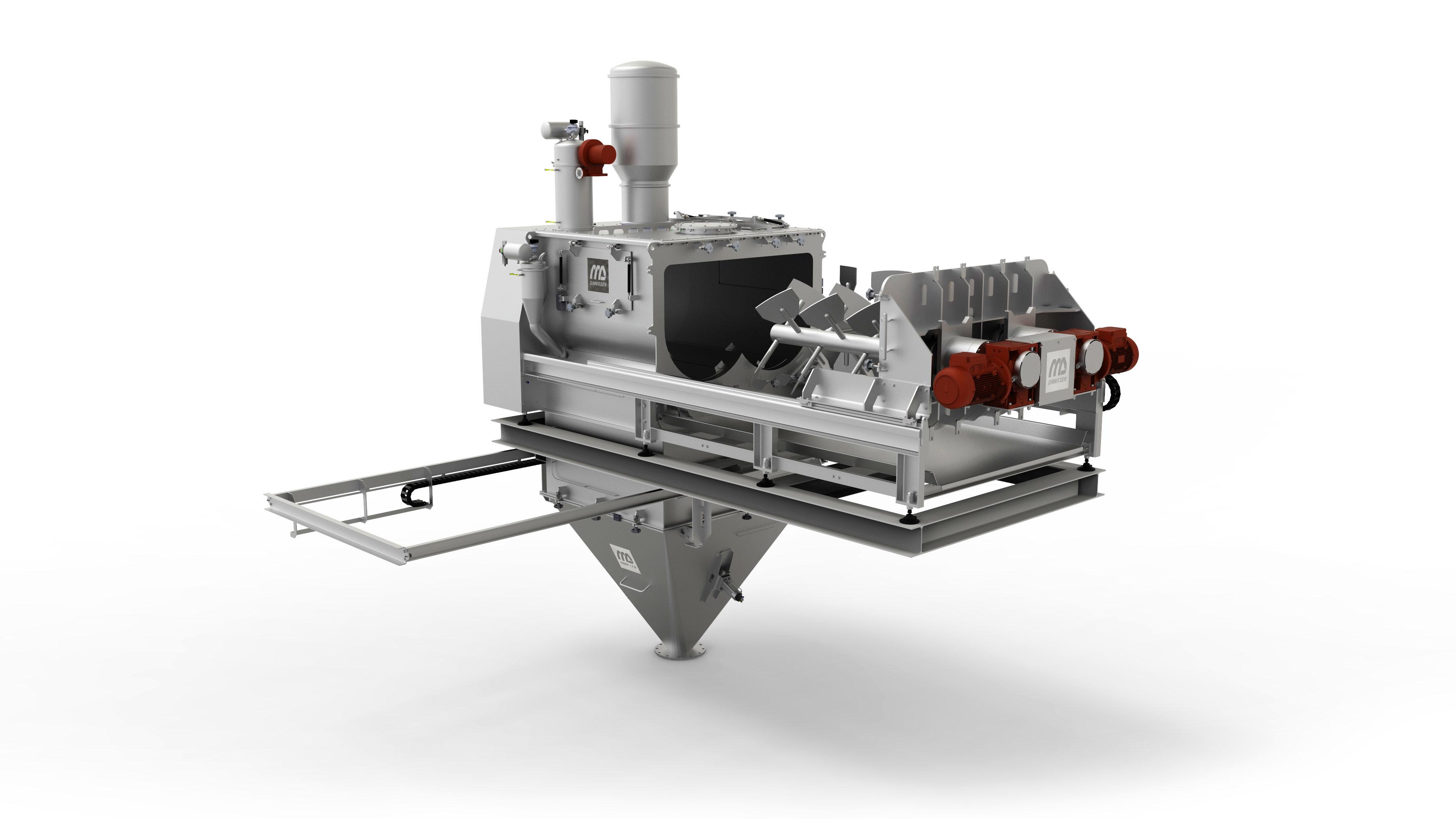

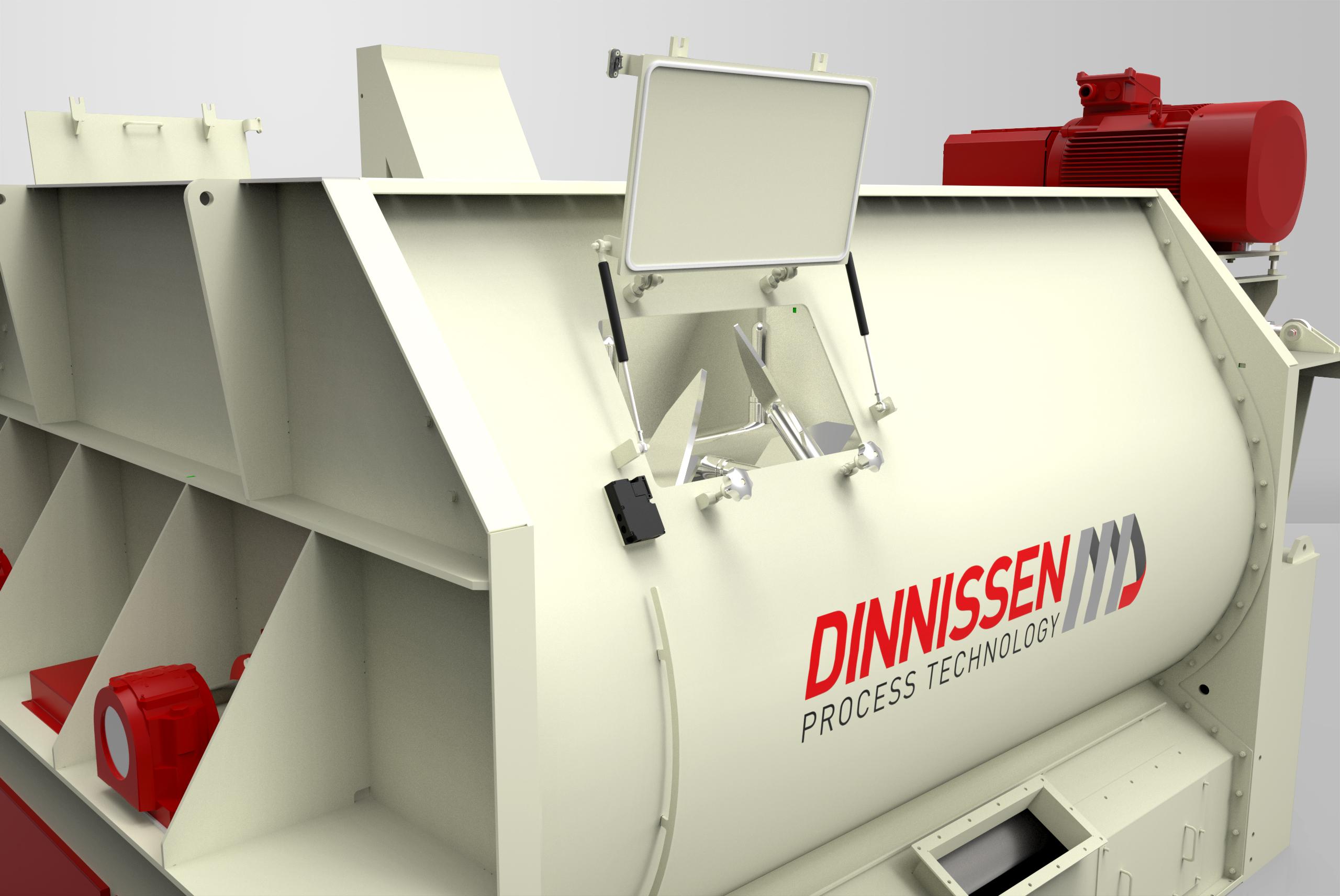

Increasingly efficient and faster production has led to a need for more and more multiprocessing machines in the food industry. That is why an increasing number of producers see the Pegasus® mixer as a good addition to their production line. The core of this double-axis Pegasus® paddle mixer comprises two opposingly-rotating shafts, making it ideally suited for ultra-fast mixing of powders, pellets grain and granular materials. The shape of the paddles and the mixing chamber ensure optimum mixing with the least possible product damage. Fragile products can also be mixed, heated and cooled with the Pegasus® mixer. You can also use this machine combined our special dosing system to mix liquids homogeneously.

The geometry of the installation is such that the sides of the mixing chamber bend slightly towards each other at the top, creating a drop shape. The negative angle of inclination on the top of the mixing chamber thus reduces the risk the processed product sticking. And the Pegasus® mixer has the added advantage of large wing-doors to allow easy access for inspection, maintenance and cleaning. If desired, you can also opt for mobile bunkers and 2 large floor hatches for complete emptying of the mixing chamber.

Would you like to know how the Dinnissen Pegasus® mixer could add value for your process? Feel free to contact one of our specialists by sending an email to [email protected] or calling +31774673555, without any obligation.