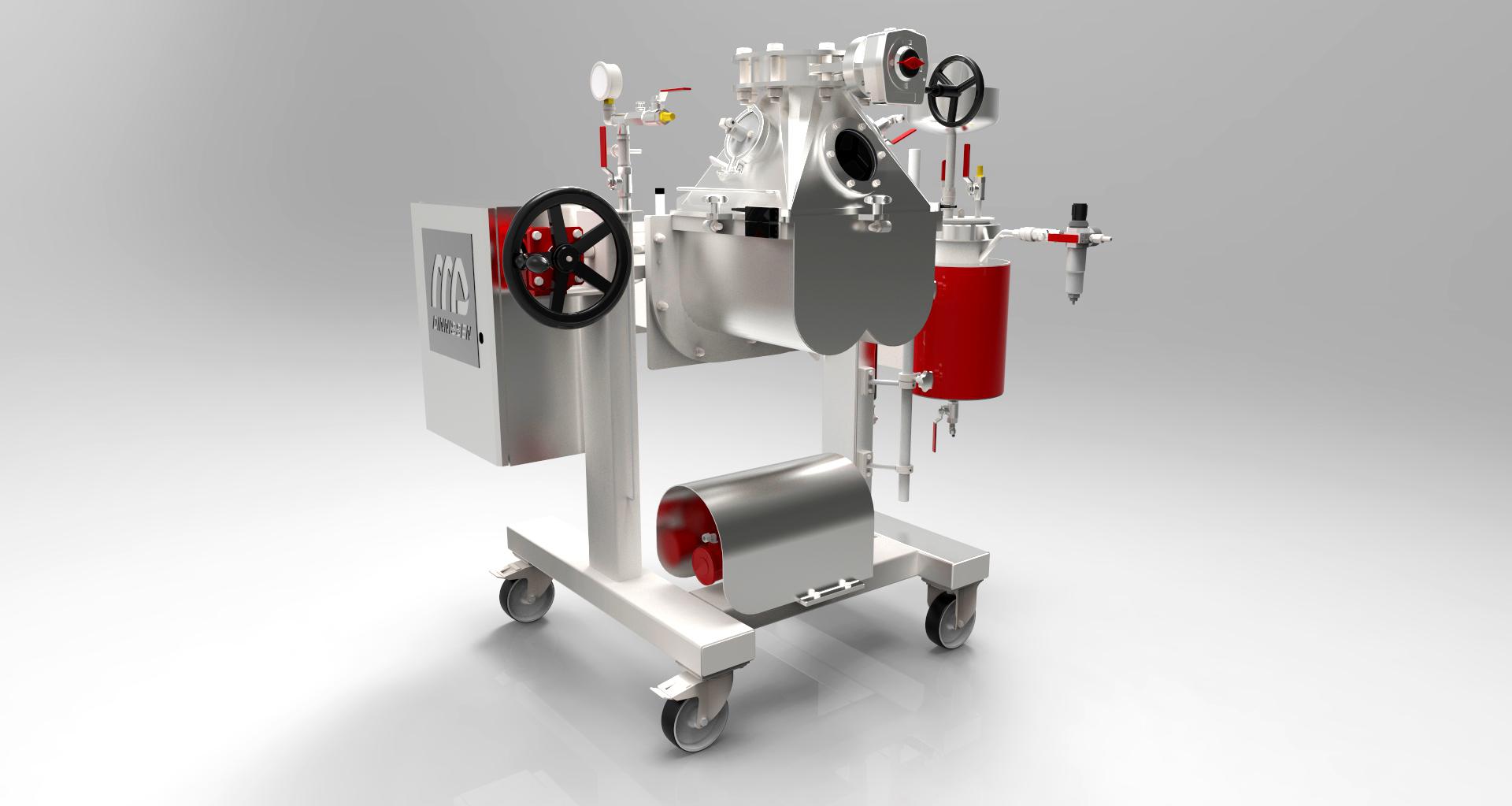

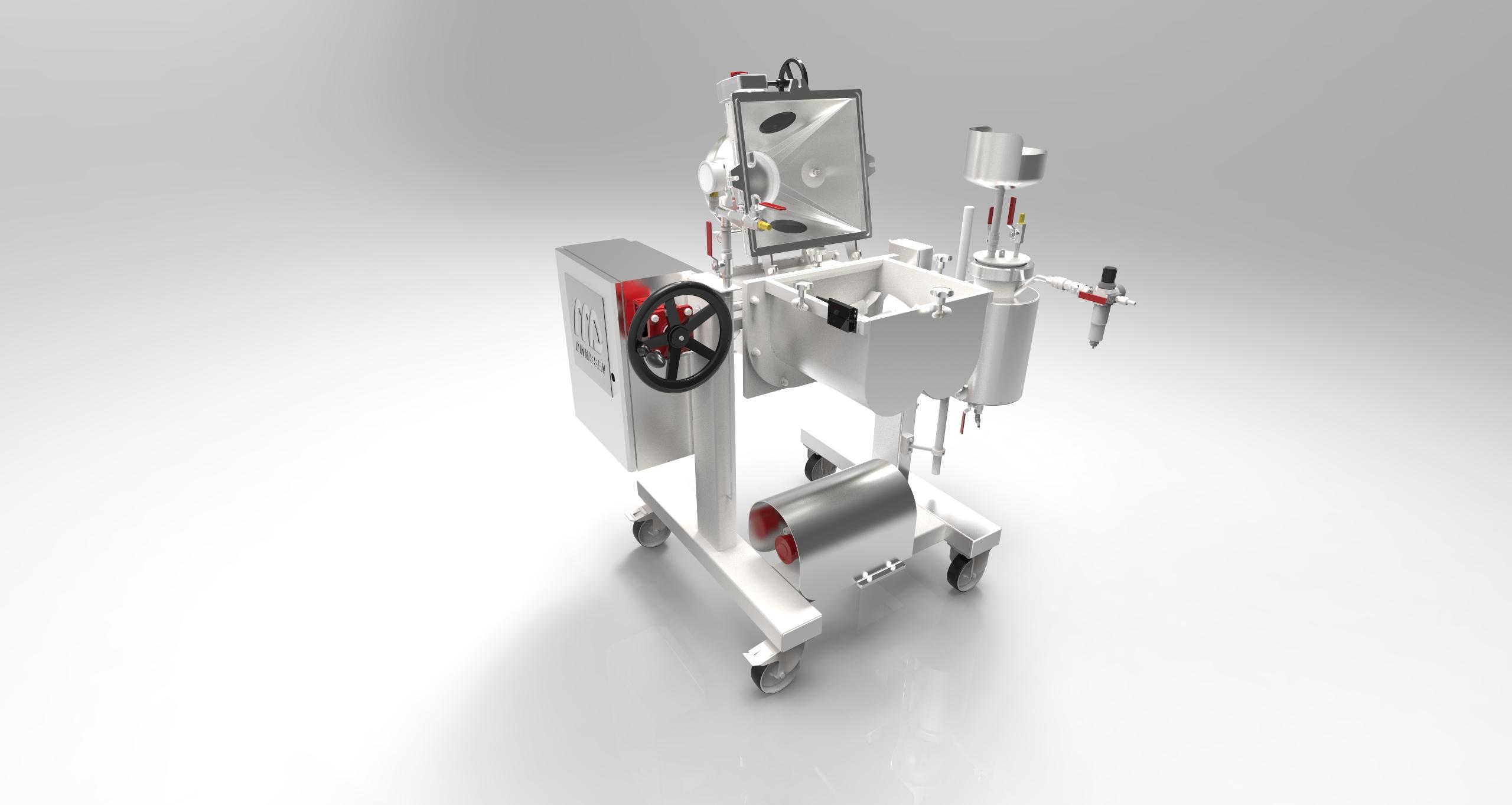

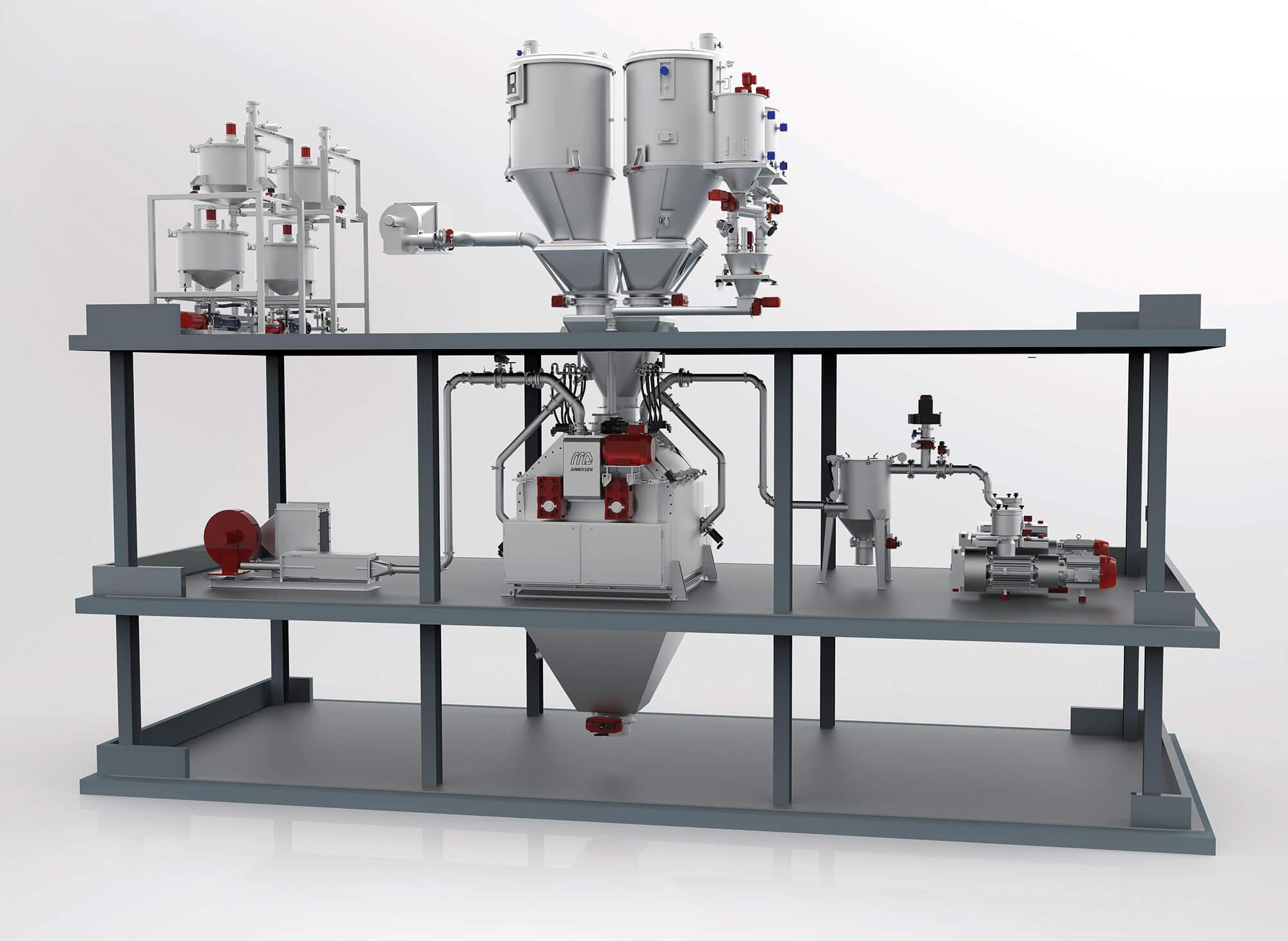

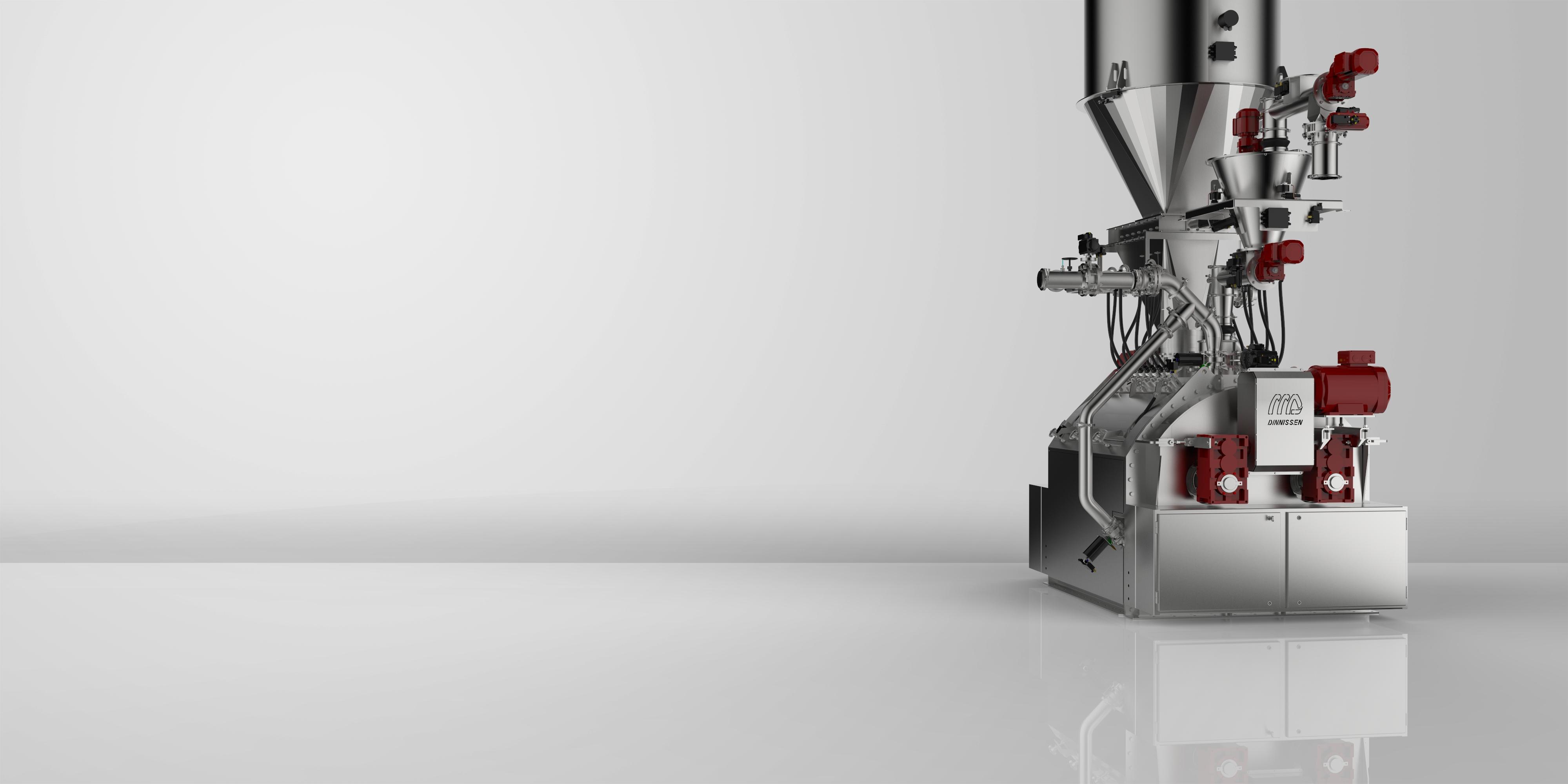

Magi-con® dosing system

Feed & Aquafeed

Animal feed manufacturers regularly face new challenges to meet their customers’ high level of quality requirements. With the Magi-con® you can flexibly produce a wide range of feed in small and large quantities in your own factory and deliver products that fully meet your customers’ specifications.