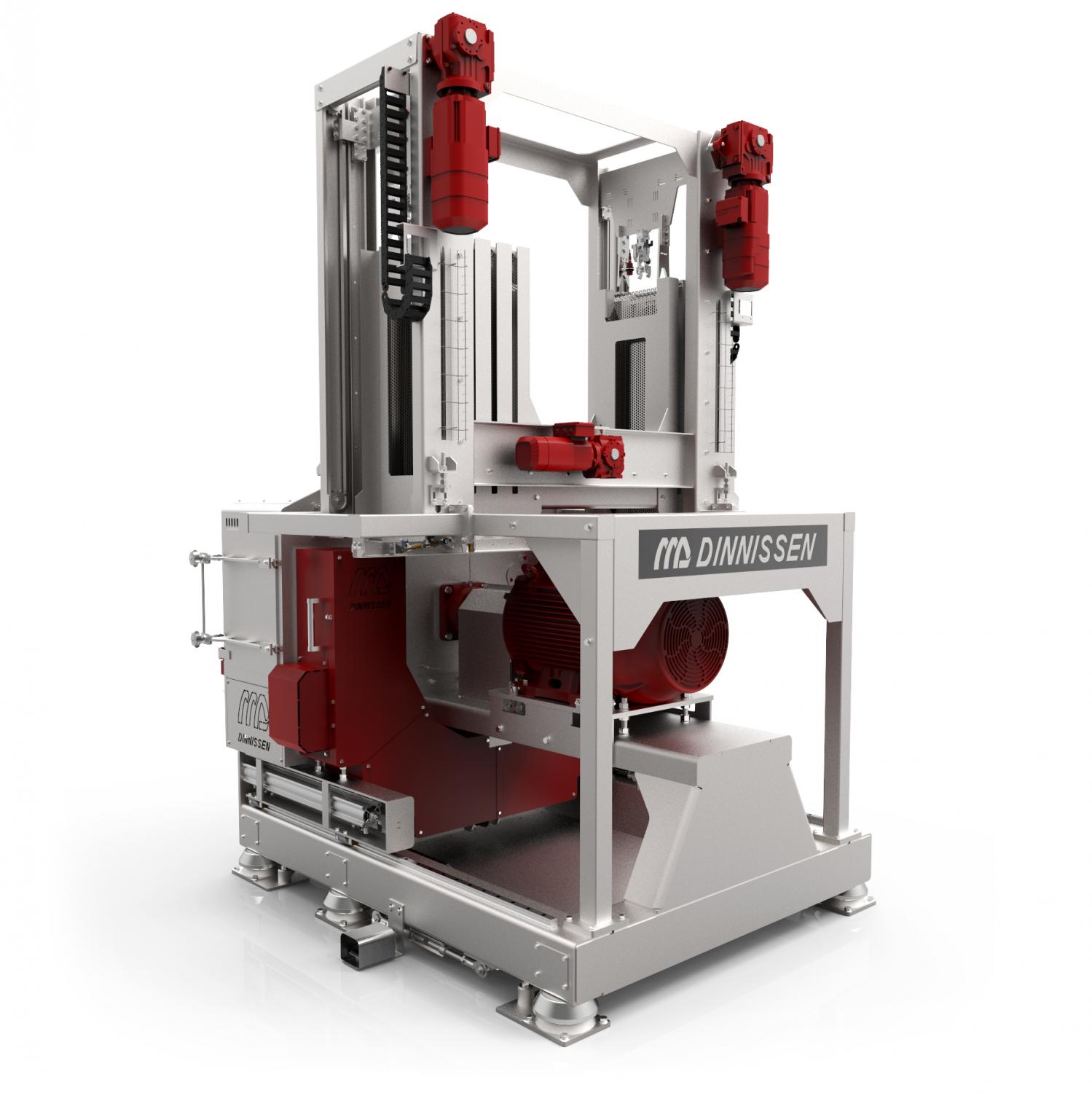

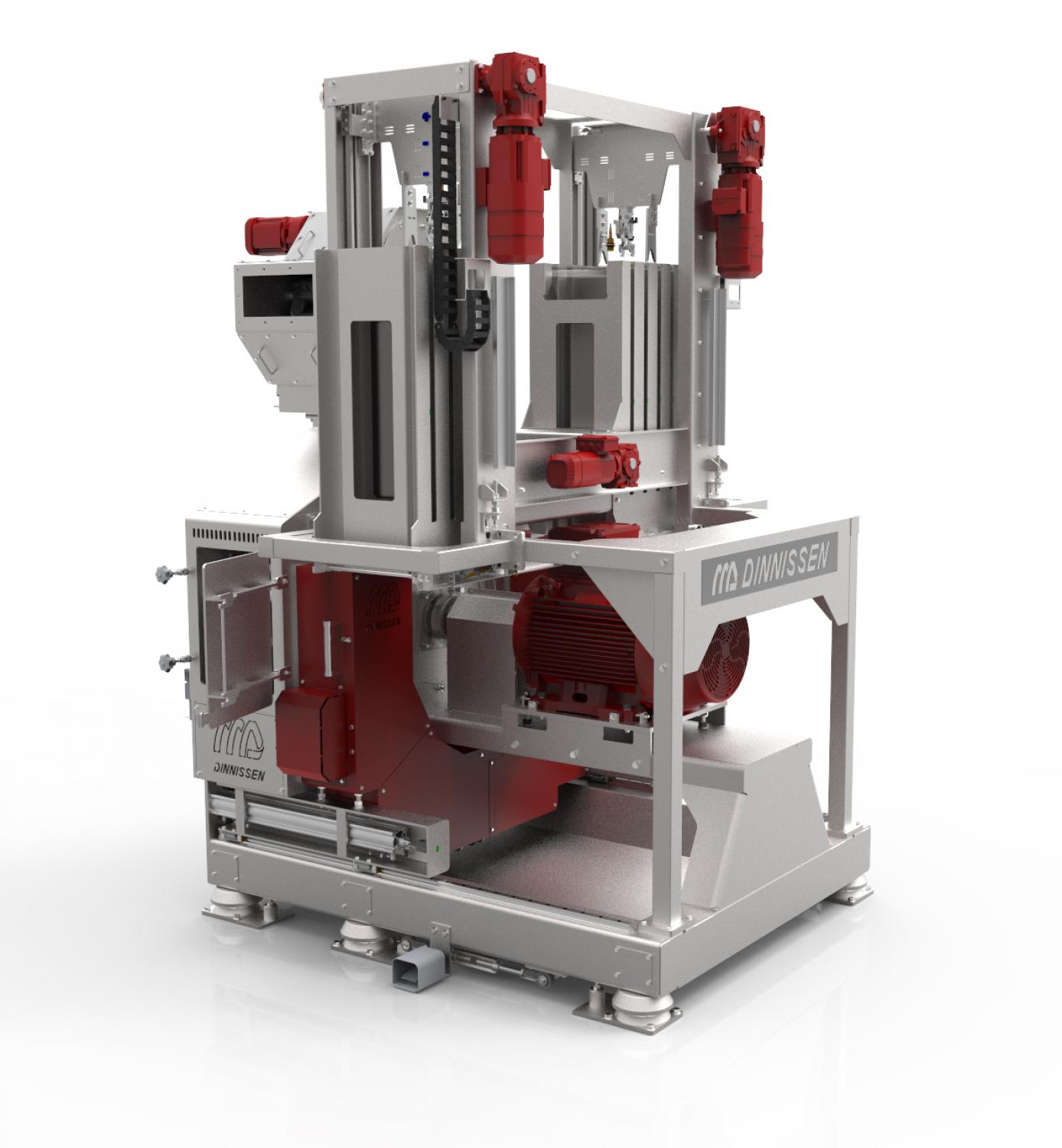

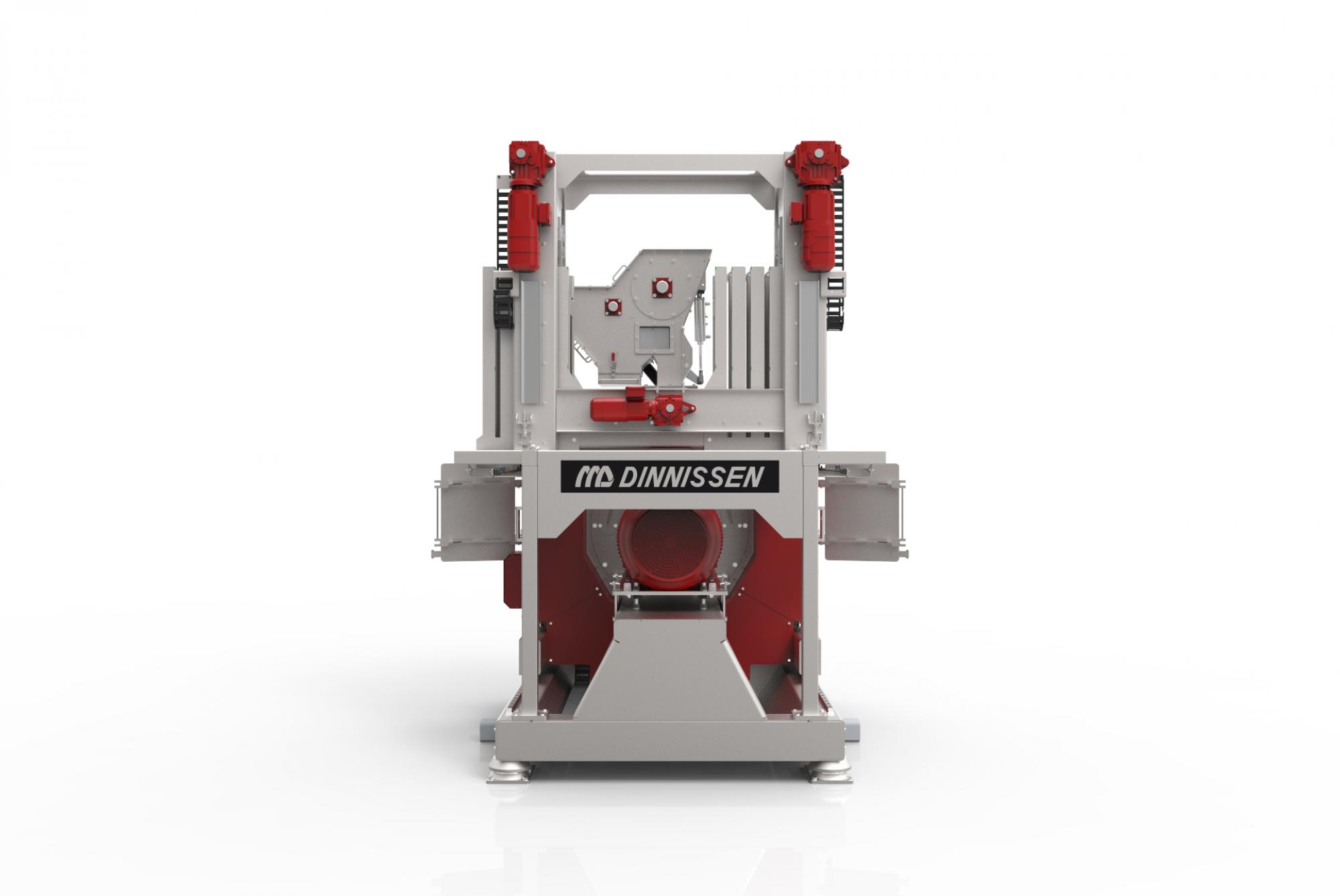

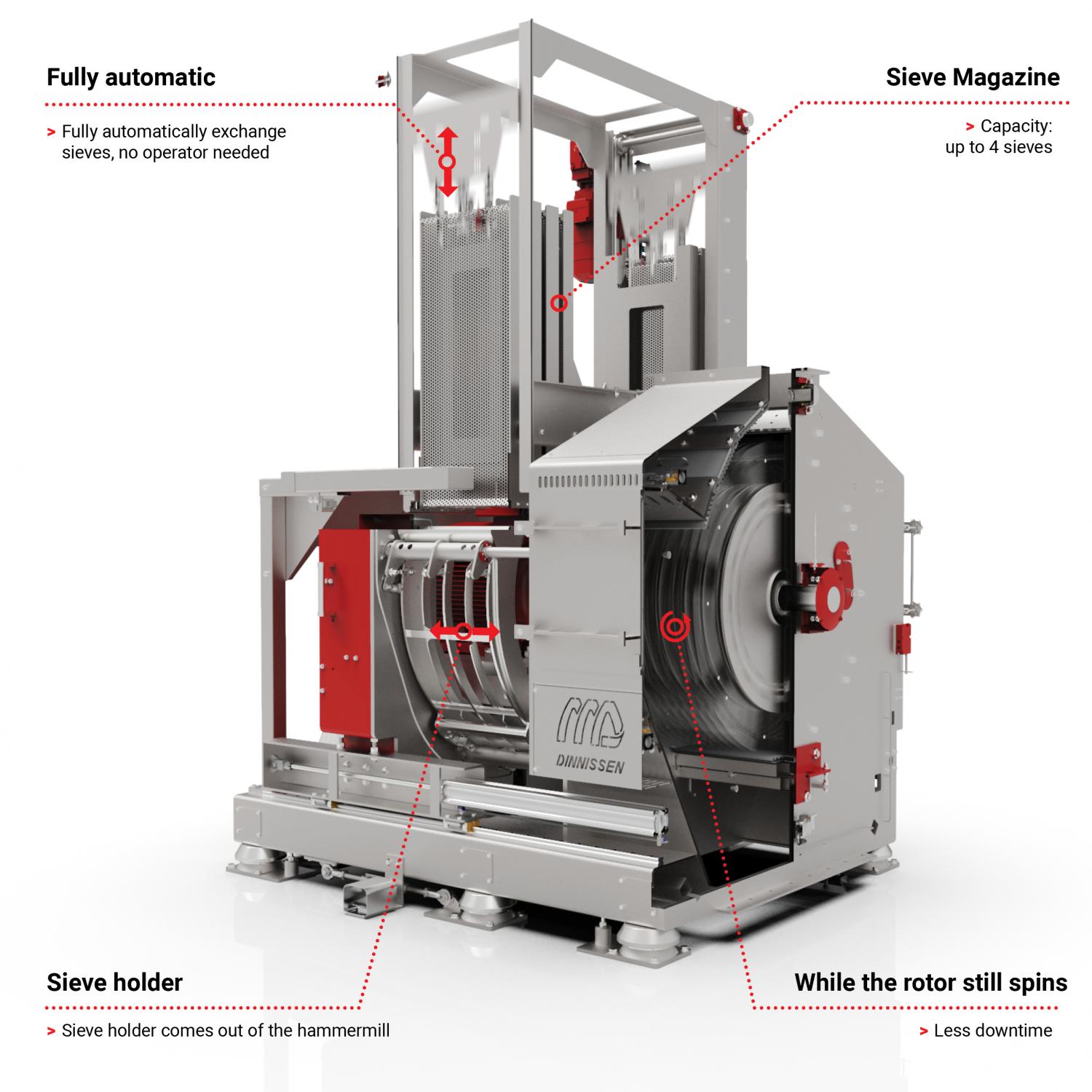

Fully automatic screen change

More efficient, safer and more secure grinding process

Normally, the hammer mill rotor has to come to a stop before the screens can be changed, which can take a long time. This can take a lot of time, especially if you want to change the sieve regularly. To ensure that manufacturers do not have to wait for this, Dinnissen has developed a fully automatic screen change system. With the Hamex® Full Automatic hammer mill, the sieve in its sieve holder is automatically driven out of the machine, after which the operator can quickly exchange or inspect the sieve manually. During this operation, the rotor can continue to rotate, which saves you approximately ten minutes of production time per screen change. That is the time it normally takes for the rotor to come to a standstill. A considerable time saving if you want to change products regularly.

During the exchange, the sieve in its sieve holder is driven out of the machine fully automatically, while the rotor continues to rotate and the housing remains closed. As a result, the hammer mill is only out of use for a short time and the safety of the operator is guaranteed. After that, the sieve is changed completely automatically, with a choice of 8 sieve positions and 4 different perforation sizes.

Would you like to know more about semi or fully automatic screen change systems? You can contact our specialists without obligation via [email protected], or call +31 77 467 35 55