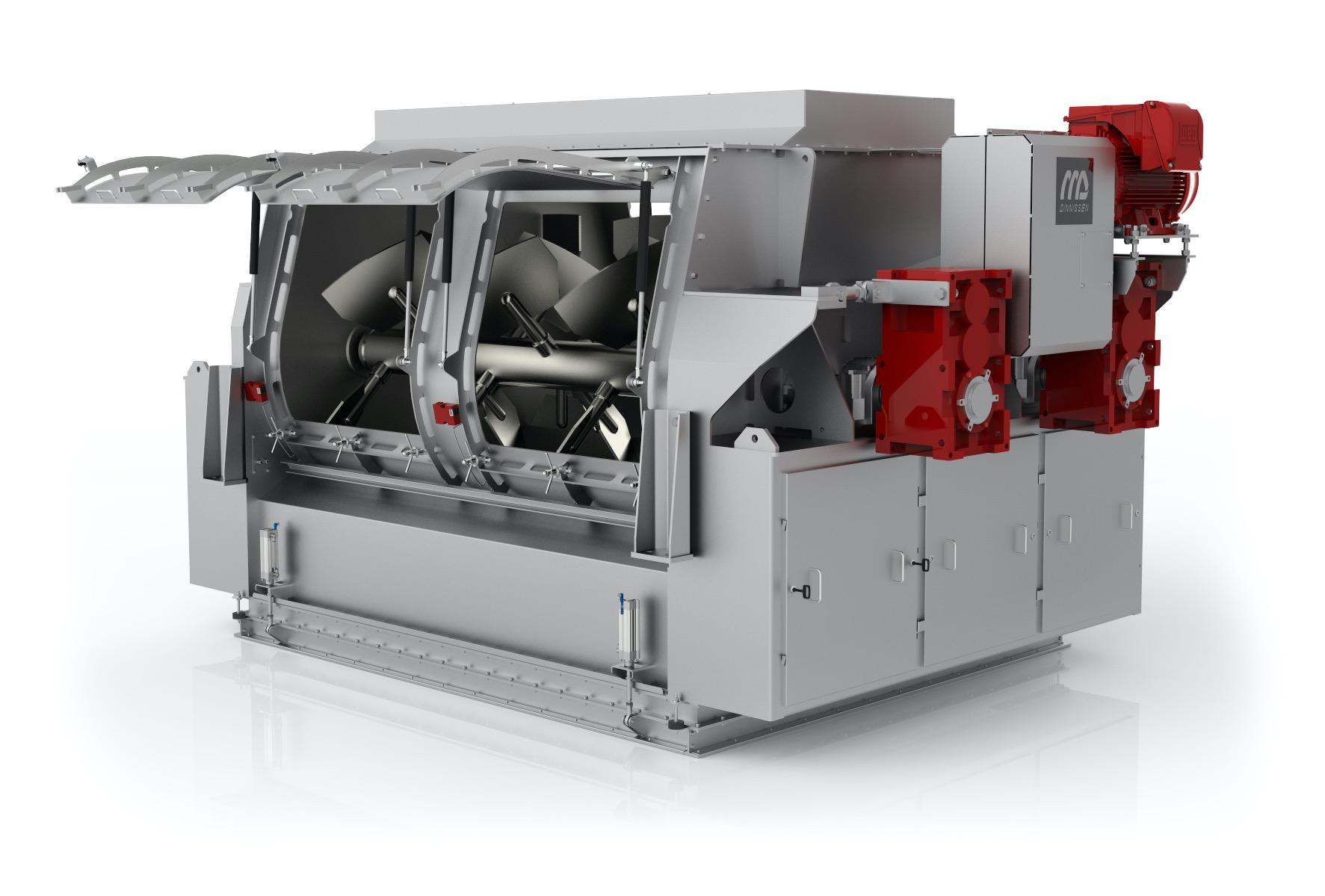

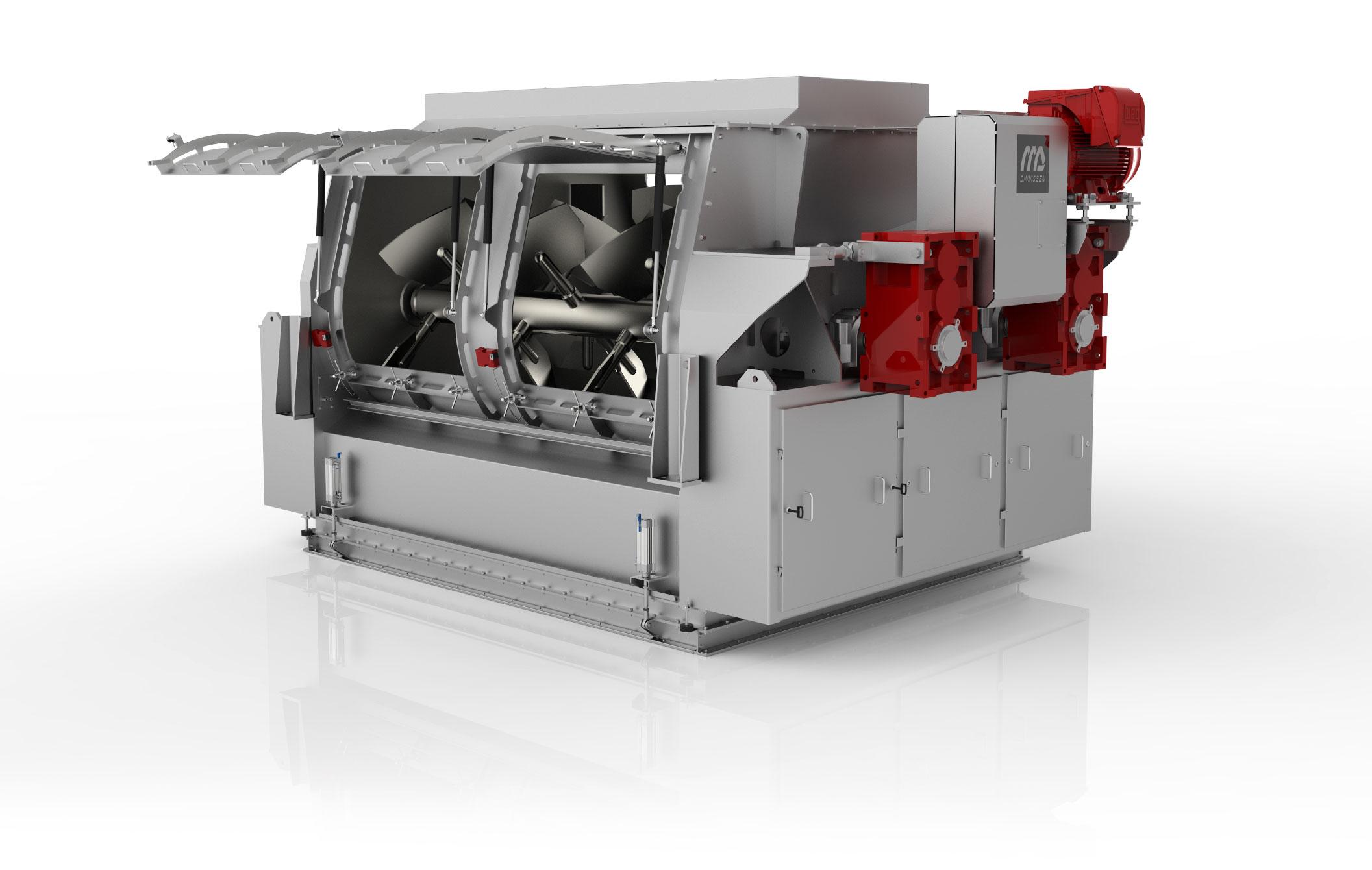

Fertilizer processing equipment

Machines designed specifically for fertilizer

Dinnissen Process Technology has worked on several projects related to processing of fertilizer. We offer a wide range of chemical specific equipments. As example the big-bag emptying station. As the name relates, the function of this machine is to empty big-bags. The way of docking of the big-bags is very ergonomic, big bags are lifted with a small crane and placed on the platform, this is called a traverse system. The hoisting is vertical, this results is no rotation.

The big-bag emptying station is one of the solutions for your process with fertilizer.

Dinnissen Process Technology has delivered several successful project for fertilizer. Below you can find the other solutions for processing with fertilizer.