Broiler feed processing equipment

Machines made by Dinnissen for broiler feed

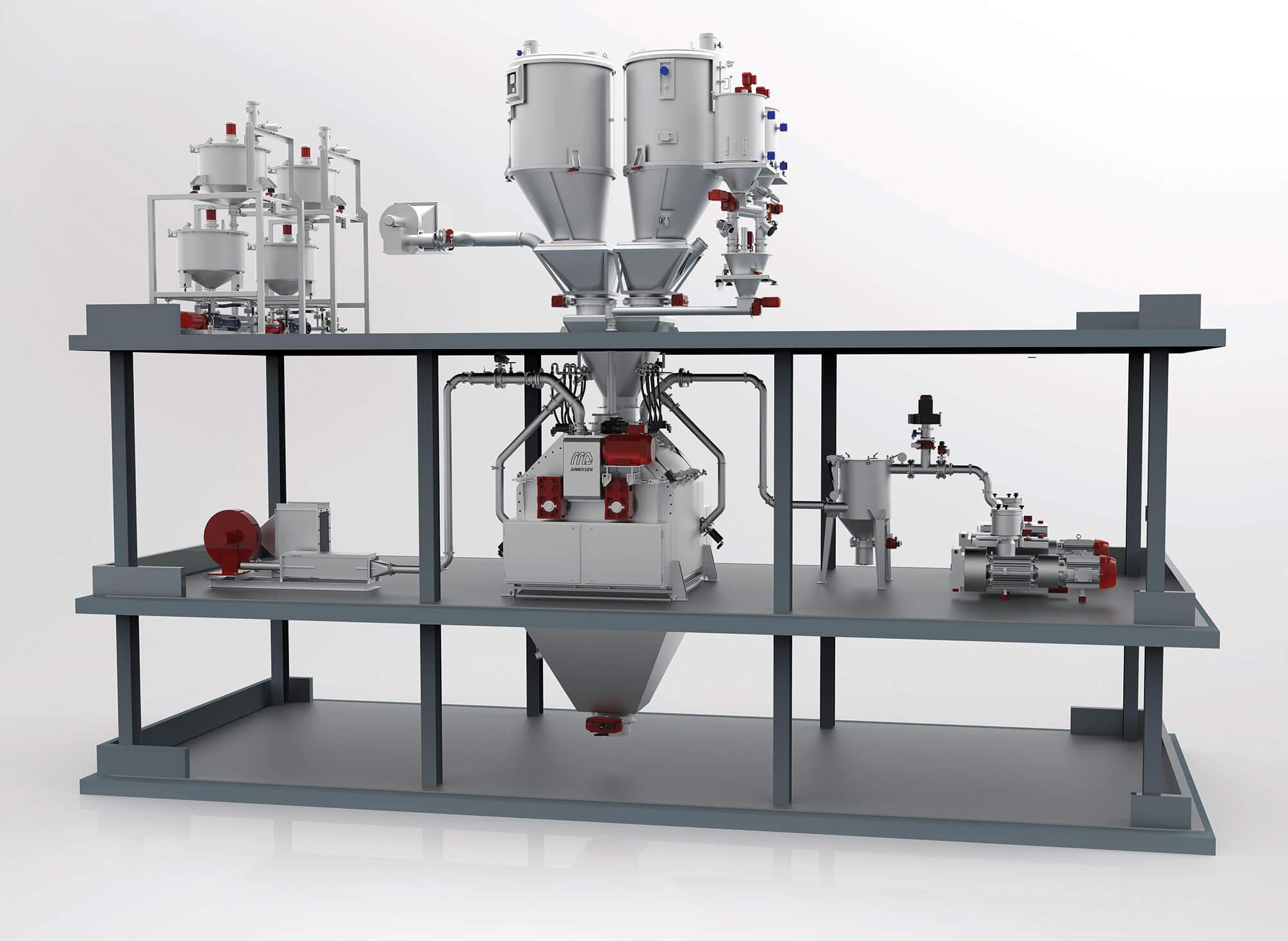

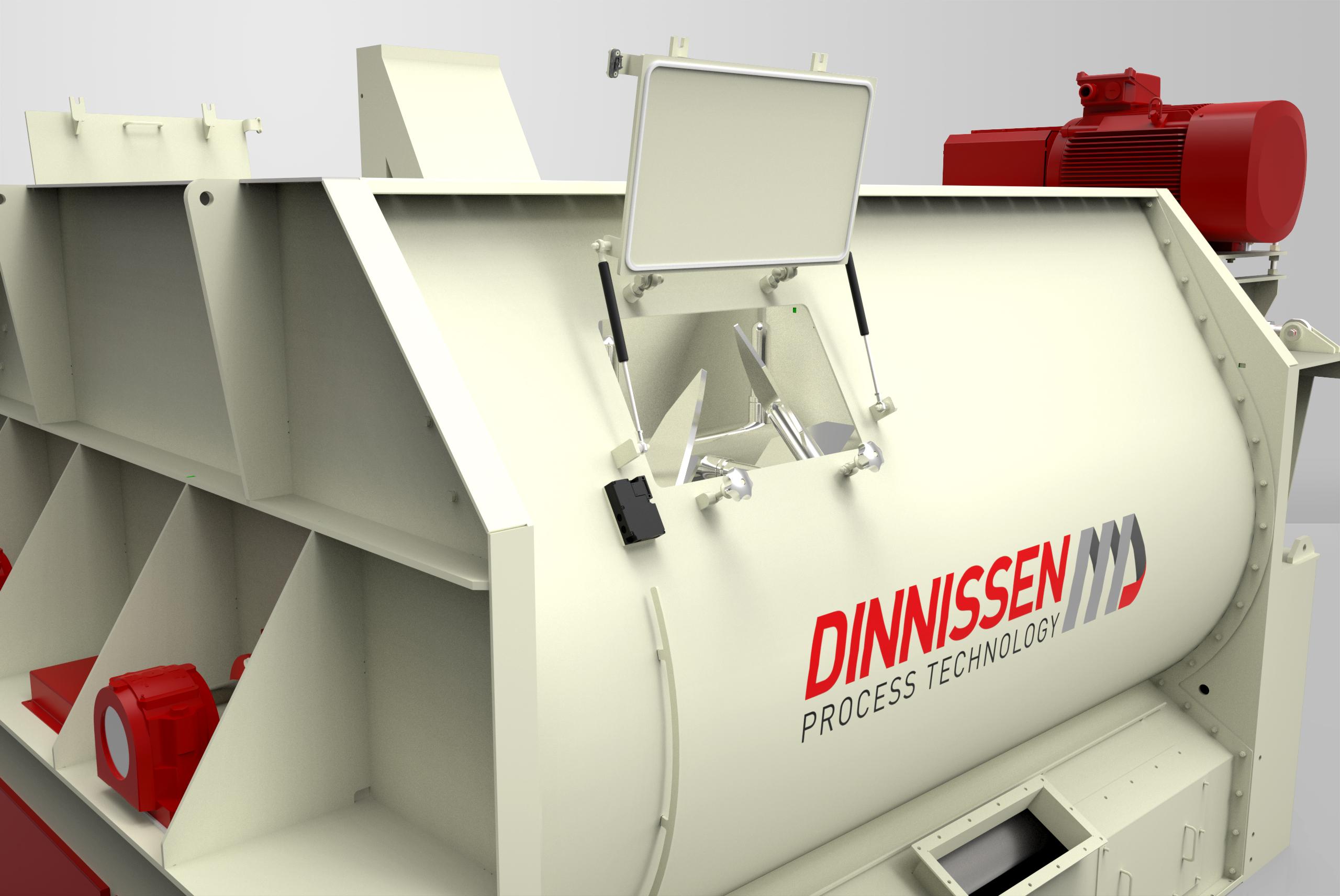

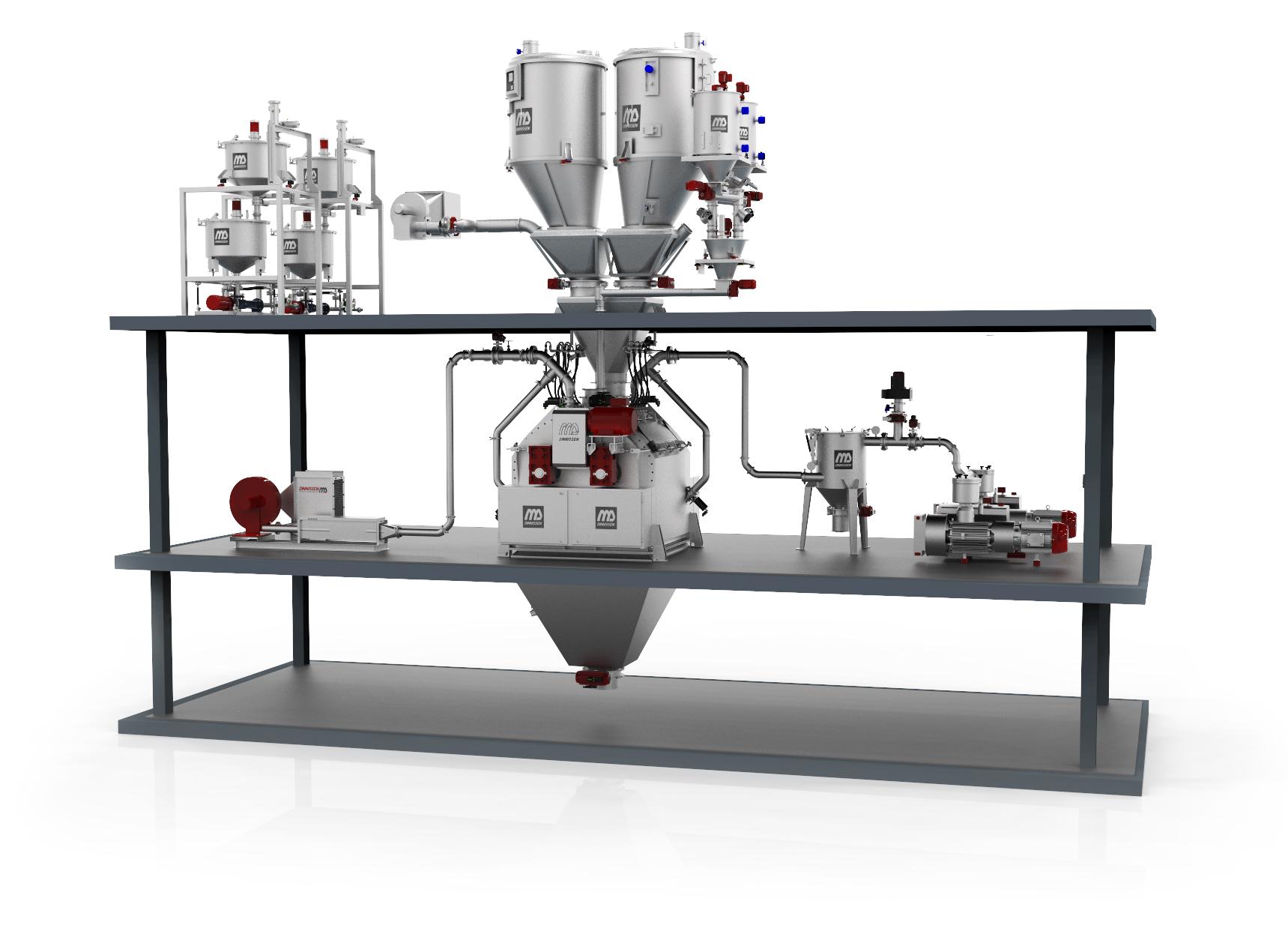

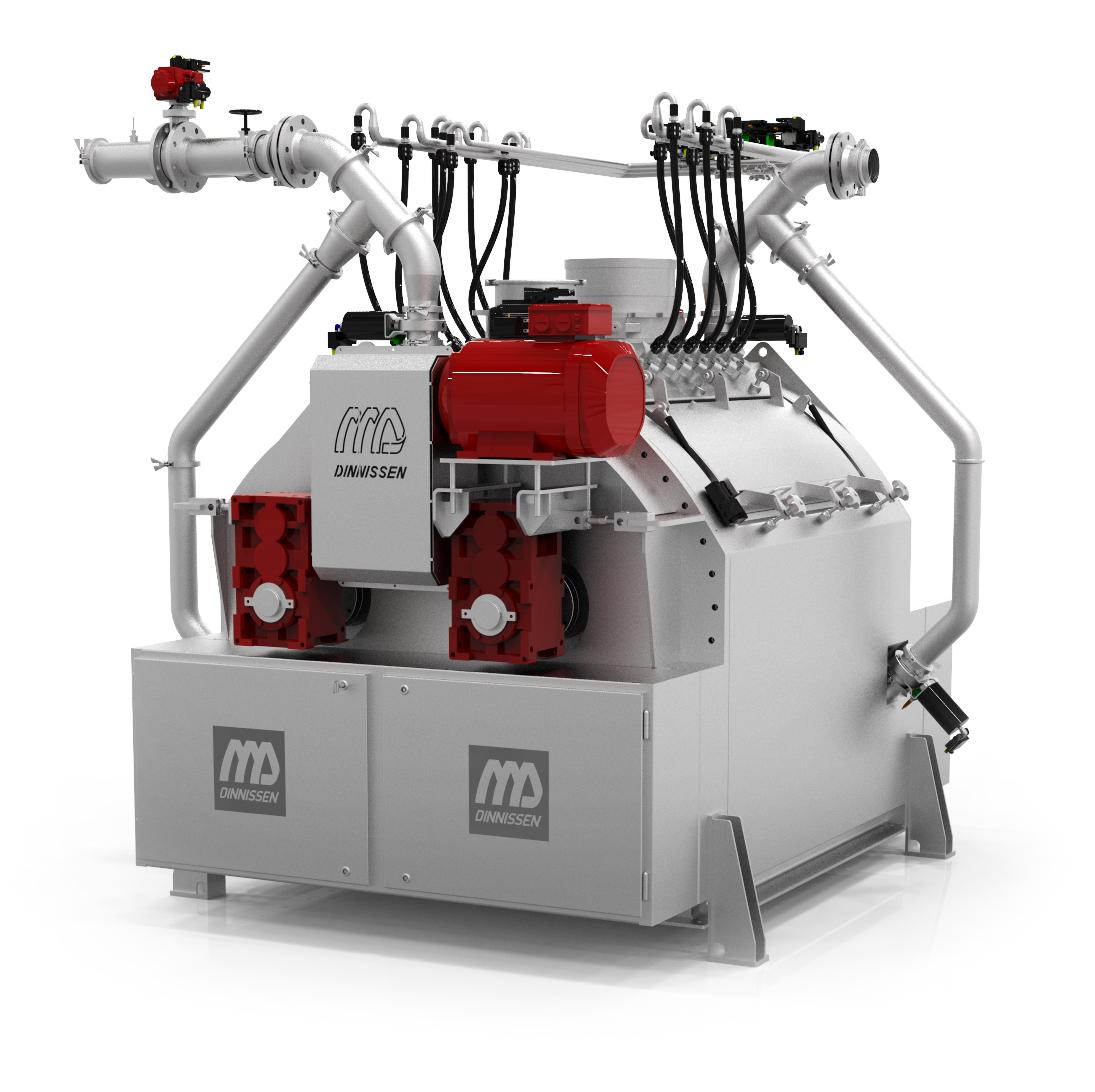

Dinnissen offers a wide range of feed specific processing equipment. Our Pegasus® MG-Mixer, Pegasus® Vacuum Coater or ZE-8 for example. These machines are tailor-made in the Dinnissen factory and meet the broiler feed requirements. The mixing time is short. The mixing process is gentle which leads to no temperature increase of the product during the mixing process.

Dinnissen Process Technology has worked on several projects related to broiler feed. We make sure that every machine is better than the last one, and we’re better than yesterday. Since our experts work closely together with our customers through the entire project we can deliver optimal solutions. Below you can find some examples of machines we made for the broiler feed industry.