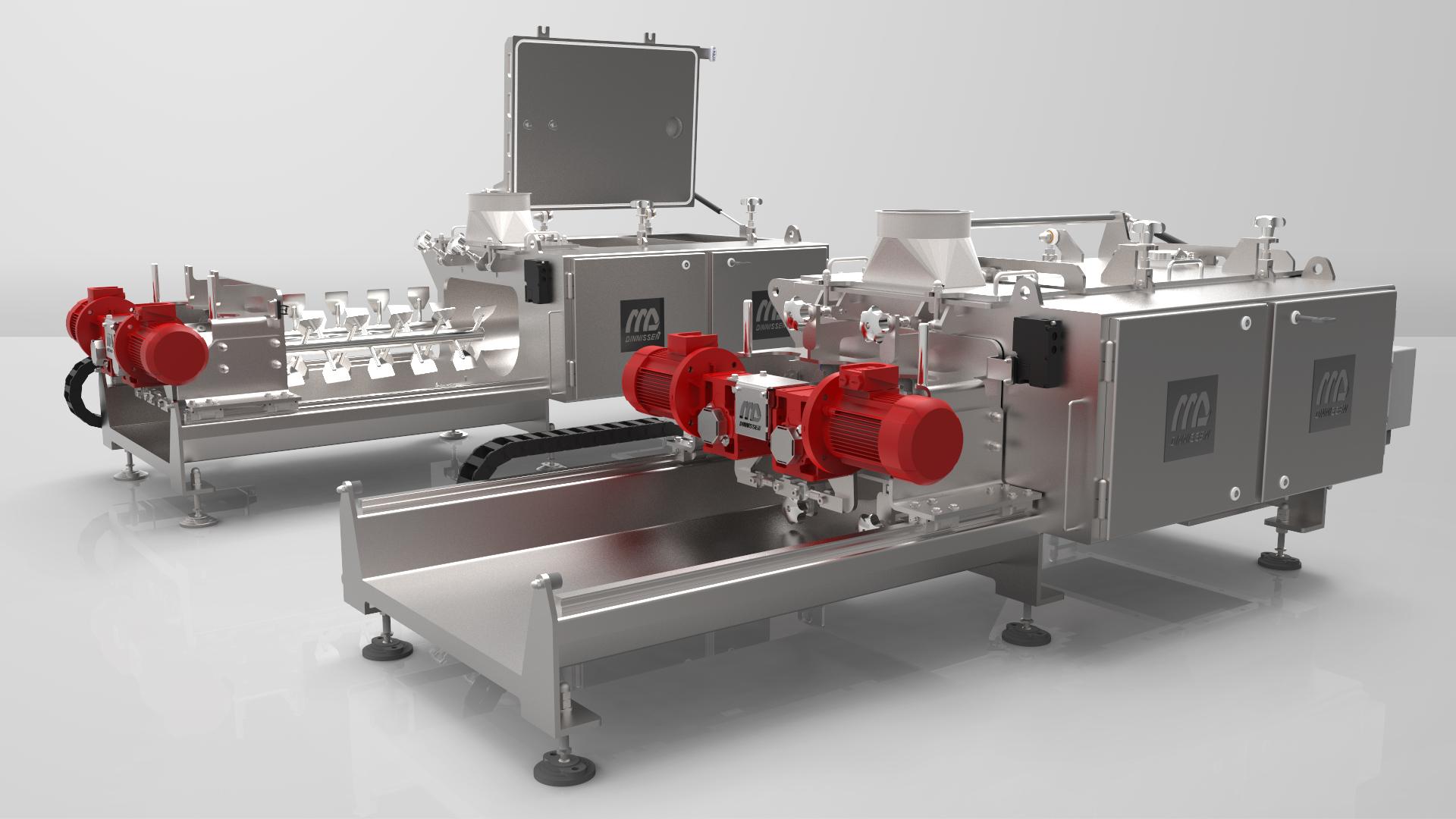

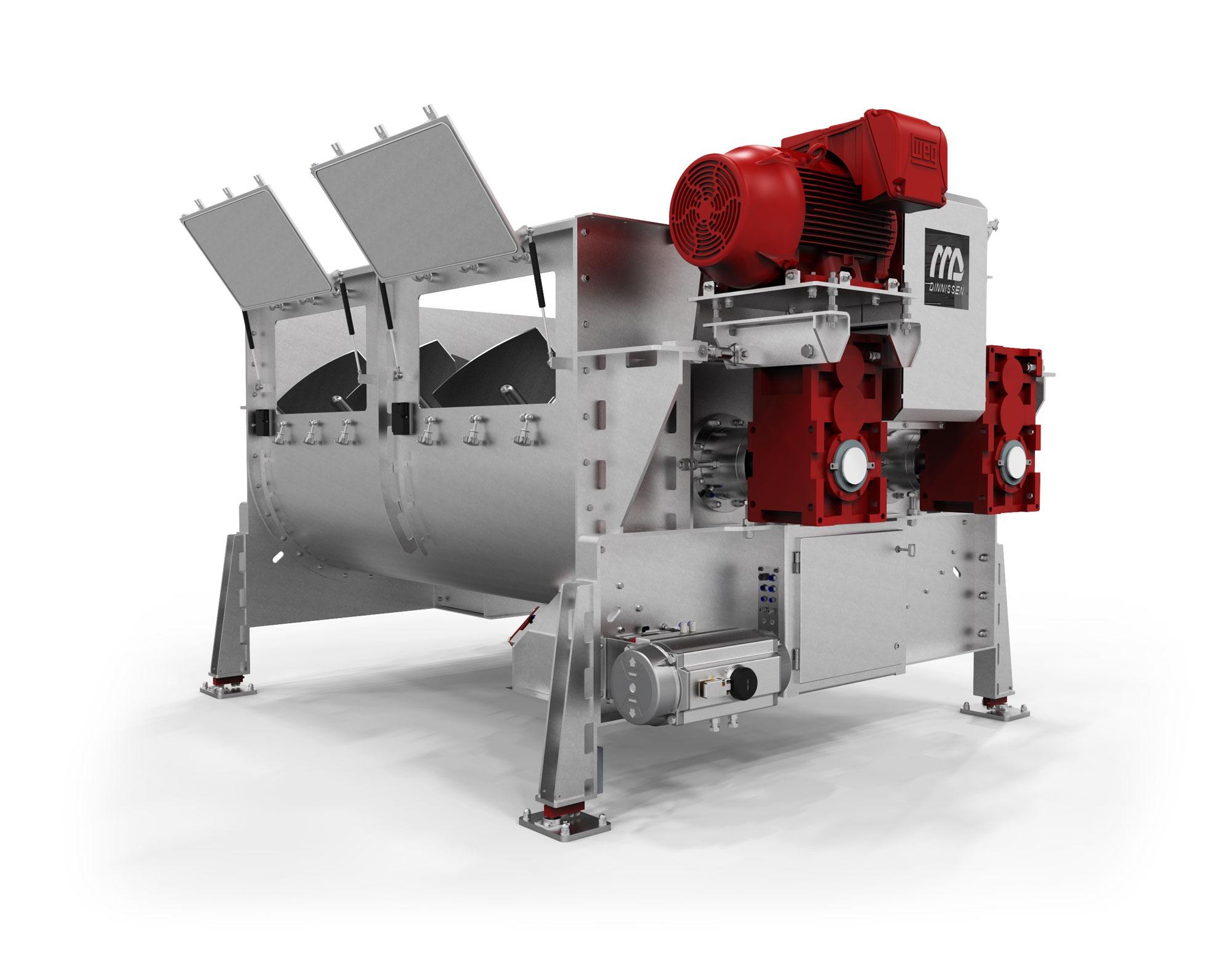

Algae processing

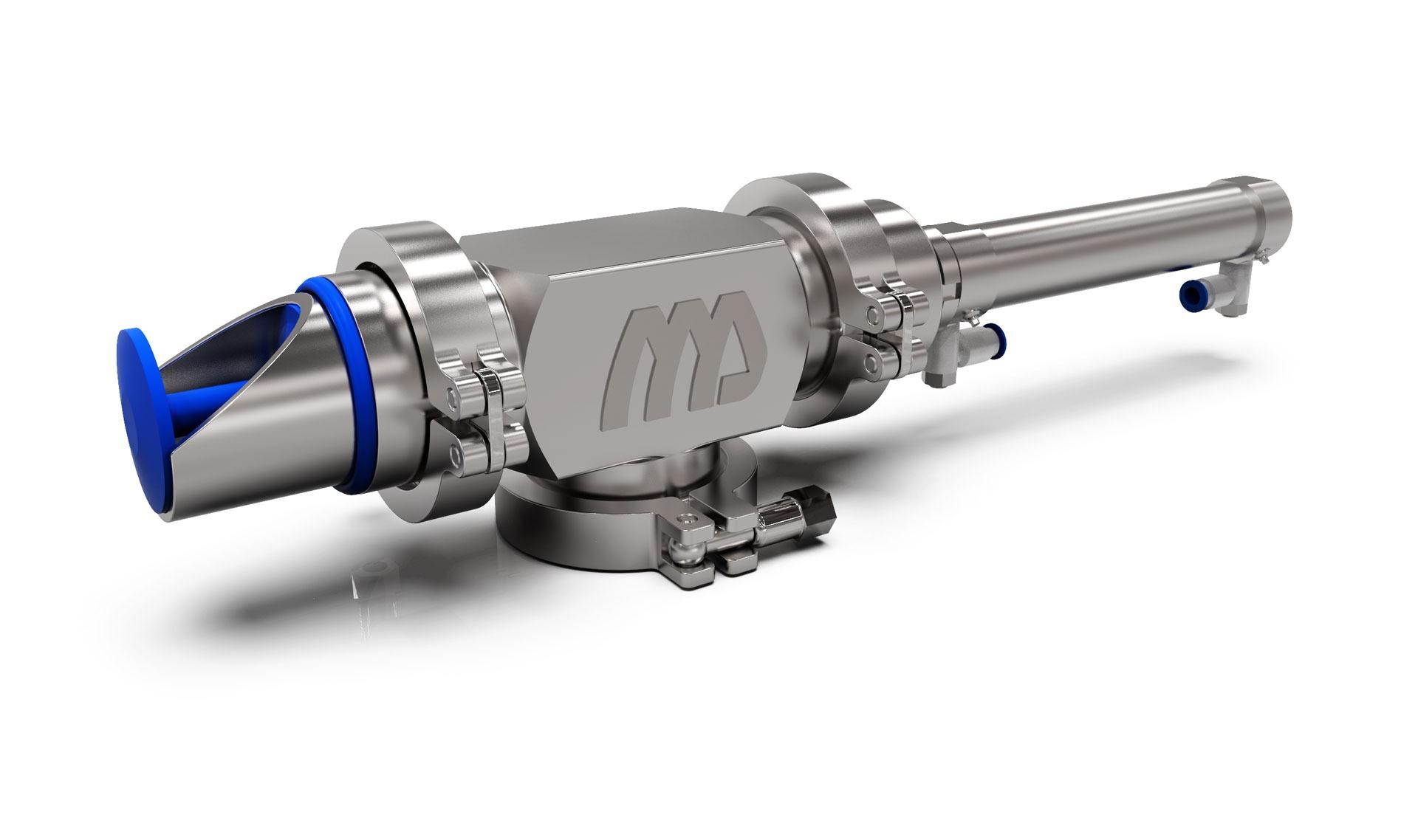

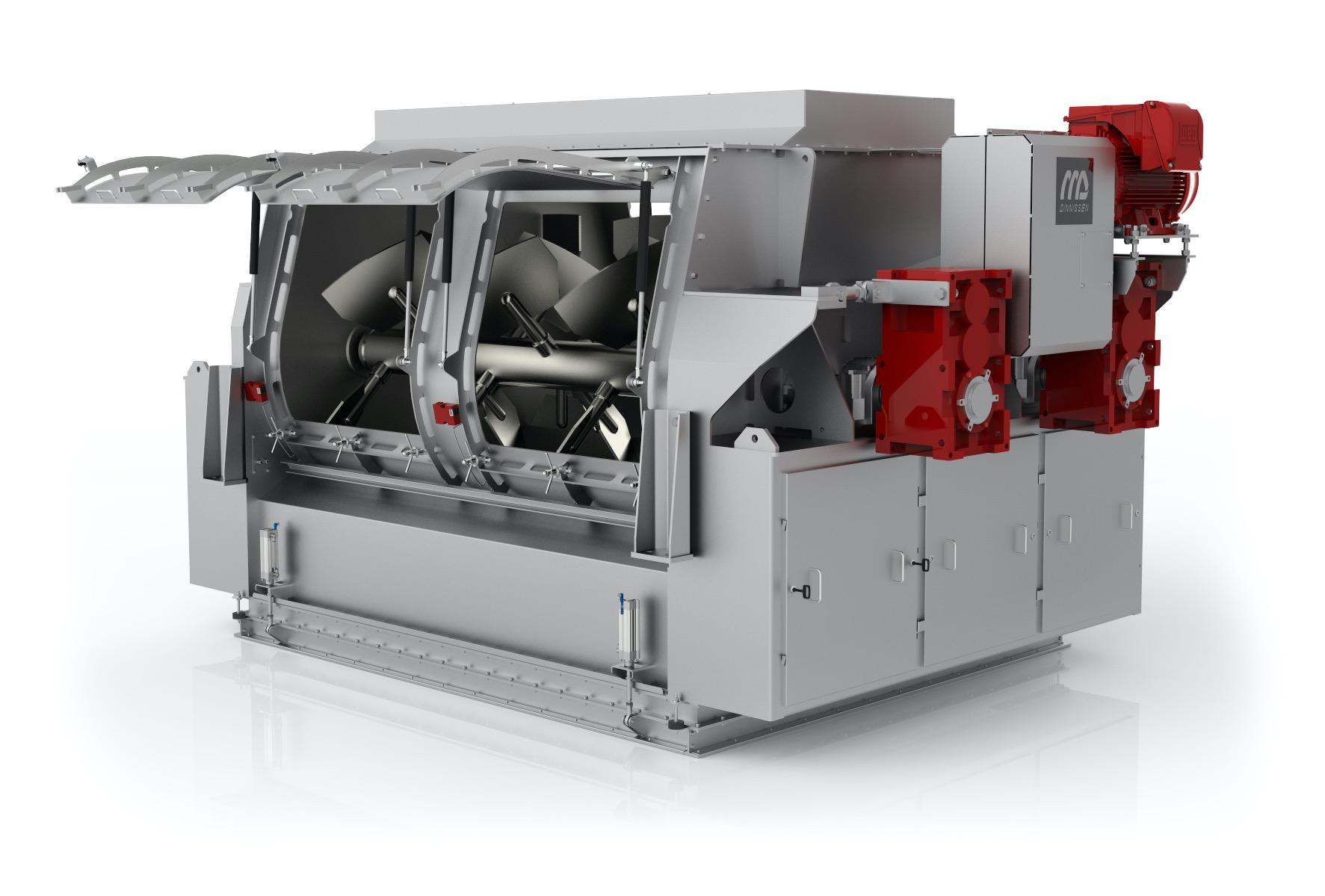

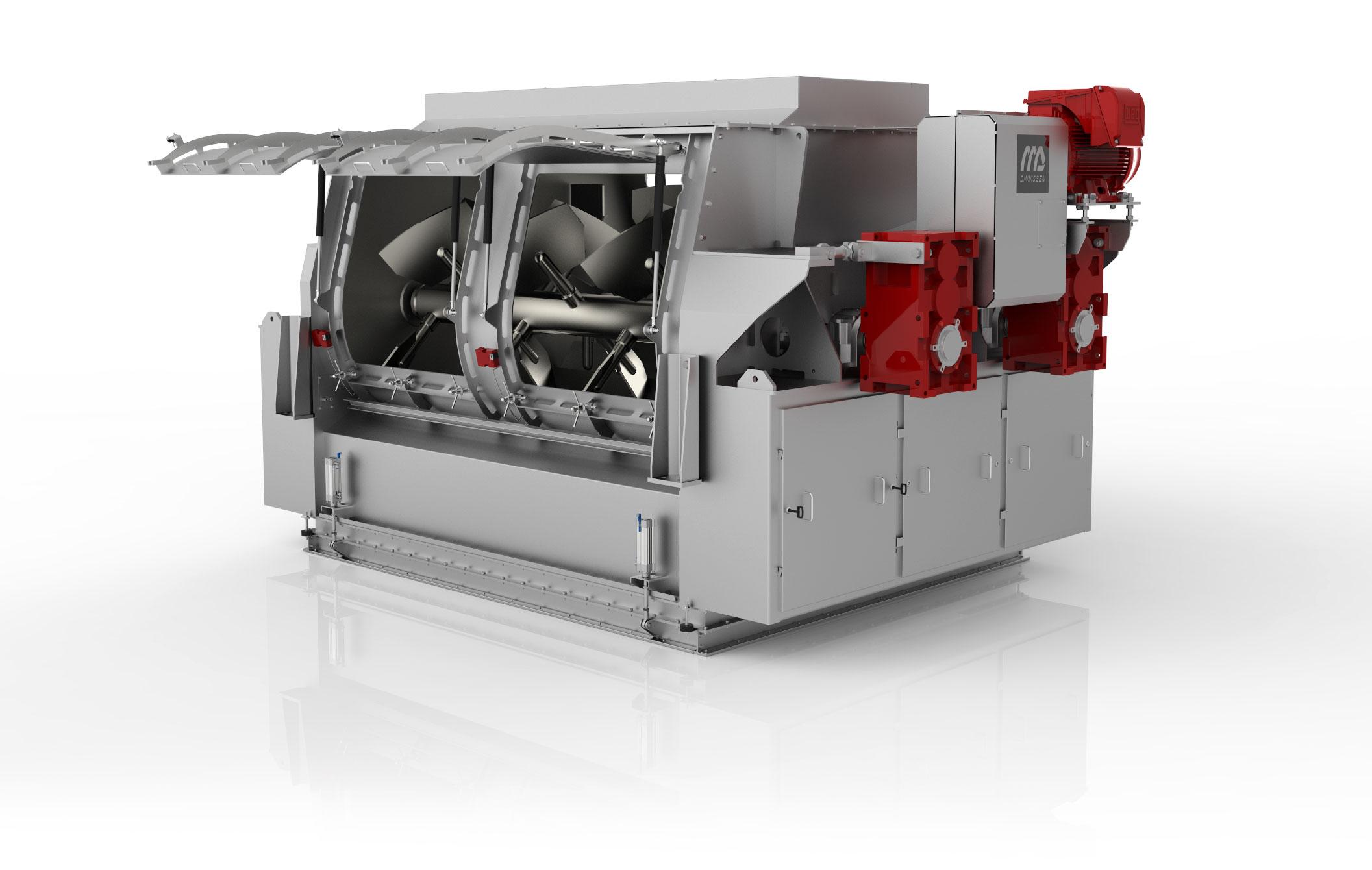

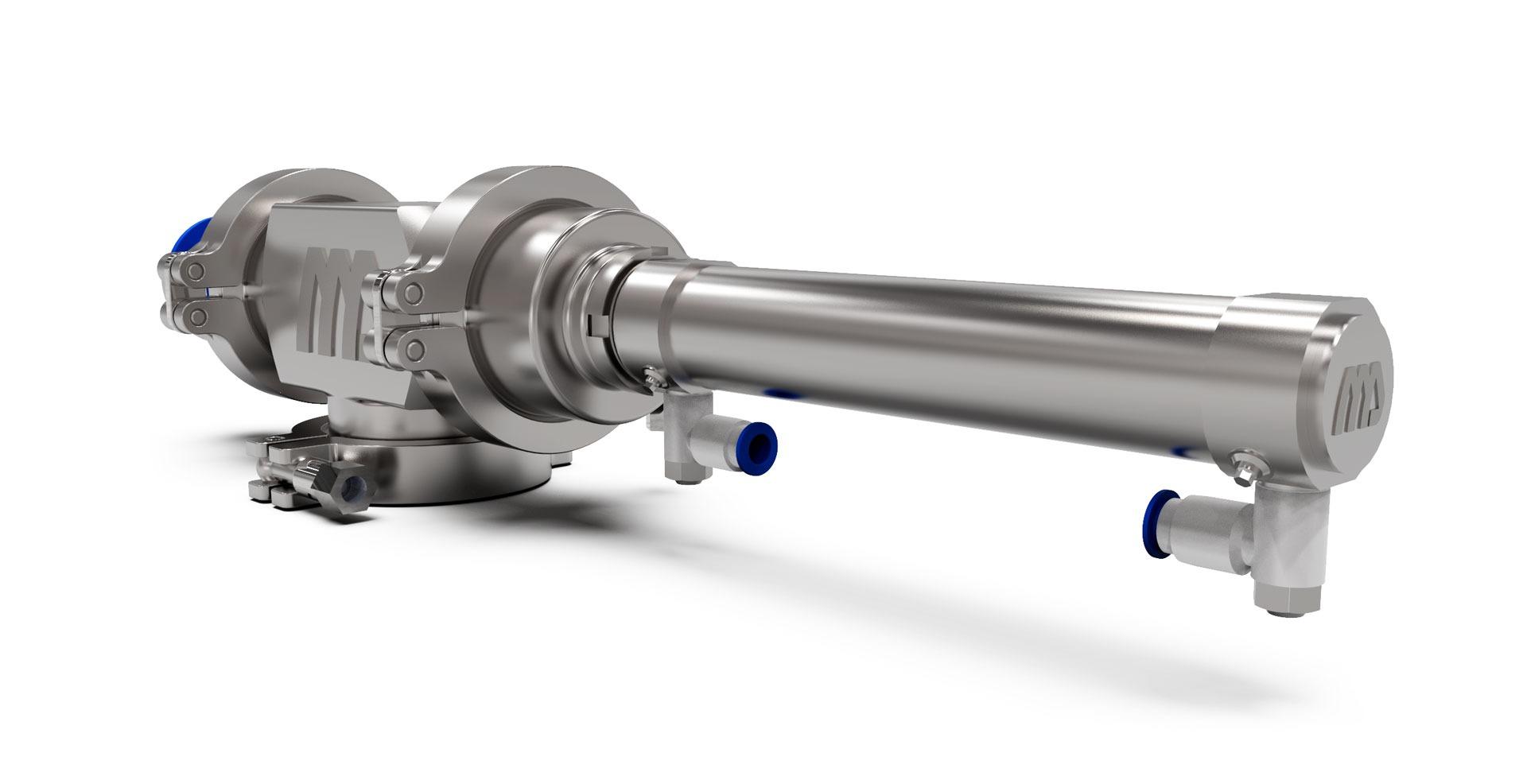

Dinnissen has developed several successful projects for the processing of algae. How does the Dinnissen sampling unit work? Is the sample unit hygienic enough for the food sector? Is there no damage on the product during the treatment? These are just some question our experts answers on a daily basis. Do you want to ask them something? Challenge them!